Imagine a world where nearly anything you can dream up can be brought to life at the press of a button. From bespoke furniture that fits perfectly in your living room to intricate, life-saving medical implants tailored just for you, the possibilities are as vast as your imagination. Welcome to the fascinating universe of 3D printing technology, a realm that has been evolving at a mind-boggling pace. As we venture deeper into this cutting-edge landscape, we find ourselves standing on the brink of a revolution that’s transforming industries, igniting creativity, and fundamentally reshaping how we manufacture and design.

In the spirit of exploration and innovation, let’s dive into the latest trends making waves in the world of 3D printing. Whether you’re a seasoned tech enthusiast, an inquisitive creator, or simply someone curious about the future, this journey promises to be as exciting as it is enlightening. Buckle up, and let’s explore!

Innovative Materials Shaping the Future of 3D Printing

Discovering the groundbreaking materials newly introduced into the 3D printing realm is akin to stumbling upon a treasure trove. Biodegradable polymers are leading the charge, rapidly gaining traction due to their sustainability and efficient lifecycle. These polymers, such as PLA (Polylactic Acid), are derived from renewable resources and offer a greener alternative to traditional petrochemical-based materials. Joining the sustainability tide are recyclable materials, which promote a circular economy by enabling the reuse of previously printed objects. Additionally, conductive filaments bring electronics into the 3D space, allowing for the creation of intricate circuits directly within the printed structures.

- Biodegradable Polymers

- Recyclable Materials

- Conductive Filaments

The introduction of composite materials is also transforming the capabilities of 3D printers. These composites, often enhanced with carbon fiber or glass fiber, deliver exceptional strength and durability while remaining lightweight. Metamaterials, designed with cellular structures, are making waves with their unique properties such as enhanced flexibility and impact resistance, paving the way for futuristic applications in aerospace and automotive industries. Even smart materials that react to stimuli like heat or light are now being explored, offering the potential for creating objects that can change shape or function dynamically.

| Material | Key Benefit |

|---|---|

| Biodegradable Polymers | Eco-friendly |

| Recyclable Materials | Promotes Circular Economy |

| Conductive Filaments | Enables Electronic Integration |

| Carbon Fiber Composites | High Strength-to-Weight Ratio |

| Metamaterials | Unique Flexibility |

| Smart Materials | Responsive to Stimuli |

Exploring Advanced Software for Smarter Printing

In the ever-evolving world of 3D printing, the adoption of advanced software is enabling creators to achieve unprecedented levels of precision and versatility. These cutting-edge programs are now offering intuitive user interfaces, helping even novices to bring complex designs to life with ease. Key features like real-time simulation and automated support generation are making the design process smoother and more efficient. Developers are focusing on enhancing the user experience by integrating capabilities such as AI-driven design optimization and cloud-based collaboration. As a result, teams can now seamlessly work together from different corners of the globe, sharing and refining their creations in real-time.

Several groundbreaking software solutions are leading the charge in smarter printing. For instance, tools are now offering parametric design functionalities that allow users to easily adjust and customize models without restarting the design from scratch. Below is a snapshot of some notable features these advanced programs provide:

- AI-driven support structures that minimize material use

- Cloud-based render farms for faster processing

- Integrated material libraries for better accuracy in results

- Real-time error detection and correction

| Software Feature | Benefit |

|---|---|

| AI Optimization | Top-notch precision and efficiency |

| Cloud Collaboration | Seamless global teamwork |

| Error Detection | Real-time correction for flawless prints |

Eco-Friendly Practices: Sustainability in 3D Printing

As the world increasingly embraces sustainability, eco-friendly practices have garnered significant attention within the realm of 3D printing. One innovative approach involves the use of recycled materials that breathe new life into waste products. For instance, discarded plastic bottles and ocean debris are being transformed into high-quality filament, reducing pollution and curbing resource depletion. Moreover, bio-based filaments, created from renewable materials such as corn starch and algae, provide an eco-conscious alternative to traditional petroleum-based options.

In addition to material innovation, the efficiency of the 3D printing process itself has seen green improvements. New low-energy printers operate with reduced power consumption without sacrificing performance. Techniques such as multi-head printing lower material waste by utilizing multiple print heads that minimize errors and iterations, optimizing material use. Additionally, closed-loop systems have emerged, ensuring that excess filament from previous prints can be repurposed, further cutting down on waste.

| Eco-Friendly Innovation | Description |

|---|---|

| Recycled Filament | Made from waste products like plastic bottles and ocean debris |

| Bio-based Filament | Sustainable alternatives derived from renewable sources |

| Low-energy Printers | Devices designed to consume less power without compromising on print quality |

| Multi-head Printing | Utilizes multiple heads to reduce errors and material wastage |

| Closed-loop Systems | Recycles excess filament, reducing overall waste |

Unlocking Potential: Applications Driving Change

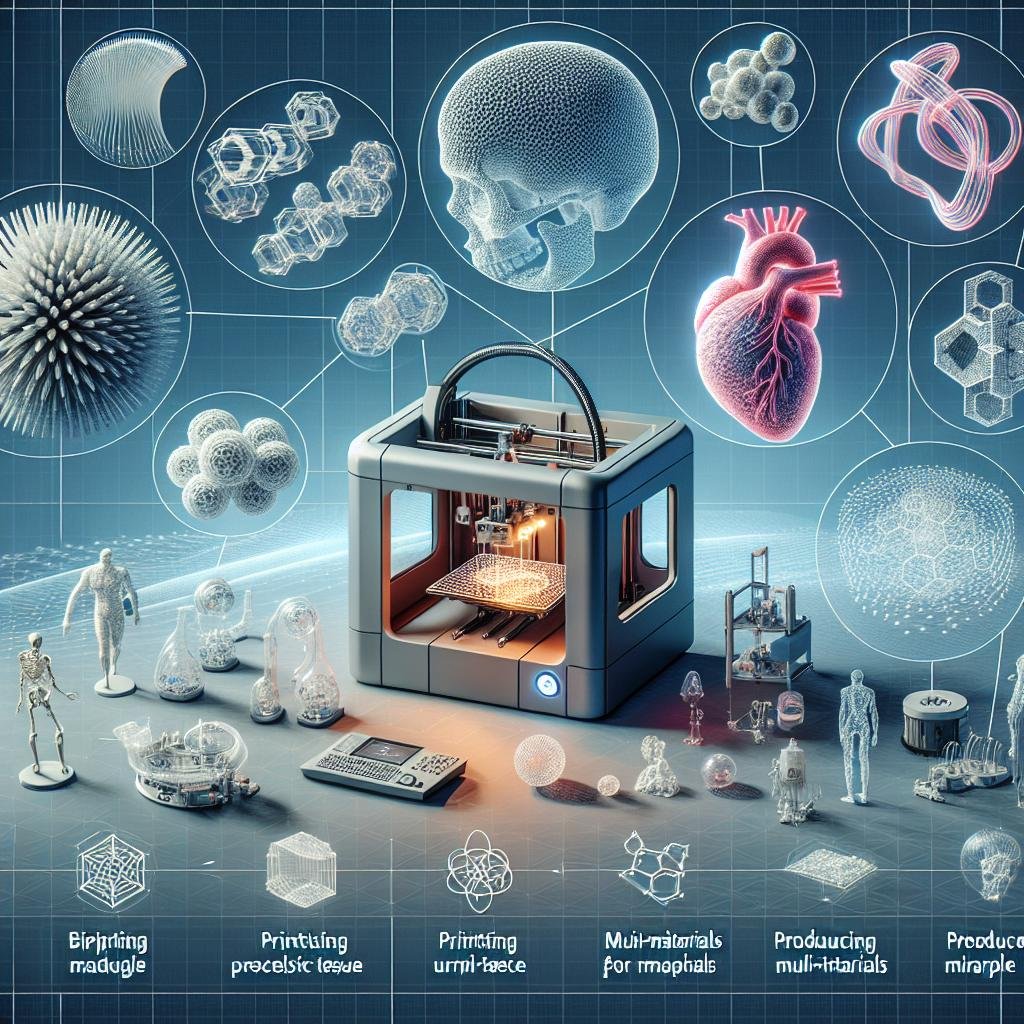

The landscape of 3D printing technology is evolving at a rapid pace, bringing a plethora of innovative applications to life. Healthcare is one of the frontrunners in leveraging 3D printing to make significant strides. From creating patient-specific implants and prosthetics to crafting detailed anatomical models for surgical planning, the medical field is reaping immense benefits. In addition, bio-printing is breaking new ground by fabricating tissues and even rudimentary organs using living cells. Educational institutions are also embracing 3D printing, using it as a tool for immersive learning experiences in subjects like biology, engineering, and design.

Another exciting frontier is sustainable manufacturing, where 3D printing is helping to reduce waste and promote eco-friendly practices. Traditional manufacturing methods often result in excess material, but additive manufacturing, typical of 3D printing, minimizes this issue. Additionally, customized fashion and wearables are another burgeoning area. Designers and engineers are now creating unique, tailored garments and accessories that fit the wearer perfectly and showcase intricate, previously impossible designs. There’s also a surge in home and office DIY projects, empowering individuals to create anything from furniture to small household items, adding a touch of creativity and personalization to everyday life.

| Application | Benefits | Impact Areas |

|---|---|---|

| Healthcare | Custom implants, Surgical models | Patient care, Surgical precision |

| Bio-printing | Fabricating tissues and organs | Regenerative medicine |

| Sustainable Manufacturing | Minimized waste, Eco-friendly | Environmental sustainability |

| Fashion and Wearables | Tailored fit, Unique designs | Fashion industry, Personal customization |

| DIY Projects | Personalized items, Creative freedom | Home improvement, Creativity |

Q&A

Q&A: Exploring the Latest Trends in 3D Printing Technology

Q1: What’s creating a buzz in the 3D printing world right now?

A: Oh, so much! One of the coolest trends is the rise of bioprinting. Imagine printing living tissues and organs! It’s a game-changer for medical research and could revolutionize transplant surgery someday. Also, sustainability is making big waves. Companies are focusing on eco-friendly materials and recycling old printed products into new creations.

Q2: That sounds futuristic! Any developments for everyday folks like me?

A: Absolutely! Desktop 3D printers are becoming more user-friendly and affordable, making it easier for hobbyists and small businesses to create their own intricate designs. Think personalized phone cases, custom jewelry, or even parts for your DIY home projects. It’s like having a mini factory right on your desk!

Q3: What about speed? Are 3D printers still as slow as molasses?

A: Speed has taken a quantum leap! Enter continuous liquid interface production (CLIP) and multijet fusion (MJF). These technologies drastically cut down on printing time while maintaining high resolution. Some printers are now capable of spitting out objects in minutes rather than hours. Talk about a time-saver!

Q4: How are different industries leveraging 3D printing?

A: Oh, the possibilities are endless! In fashion, designers are pushing the boundaries with custom-fitted, on-demand clothing and accessories. The automotive industry is printing lightweight car parts, reducing manufacturing time and costs. Even culinary arts are getting in on the action with 3D-printed food. Chocolate sculptures, anyone?

Q5: What’s the latest in 3D printing materials?

A: The material game is strong! Developers are creating new composite materials that are stronger, lighter, and more versatile. From flexible filaments ideal for wearable tech to metal powders for aerospace engineering, the array of options is mind-blowing. And let’s not forget the biodegradable plastics for a greener planet!

Q6: Are there any new software advancements related to 3D printing?

A: You bet! New AI-powered design software is helping even novices create complex models with ease. These programs can optimize designs for strength, weight, and material efficiency, often suggesting improvements you wouldn’t think of. It’s like having a design assistant on your computer!

Q7: Anything for the tech geeks to geek out over?

A: Oh, totally! The integration of IoT (Internet of Things) and 3D printing is a real kick. Imagine a printer that can monitor its own performance, predict maintenance needs, and even order its own replacement parts. Perfect for those who love the perfect blend of hardware and smart tech!

Q8: What does the future hold for 3D printing?

A: The sky’s the limit! We’re talking about space-grade 3D printers that can build habitats on other planets, and hyper-customization in everyday products tailored to individual needs. As innovation continues to surge, 3D printing is poised to transform not just industries, but the very fabric of how we create and interact with the world.

Q9: Any final thoughts for someone interested in jumping into the 3D printing scene?

A: Dive in, have fun, and don’t be afraid to experiment! The 3D printing community is super supportive, and there’s a treasure trove of resources out there to get you started. Whether you’re a curious newbie or a seasoned tinkerer, there’s never been a better time to explore this incredible technology. Happy printing!

To Wrap It Up

And there you have it! The ever-evolving realm of 3D printing technology continues to expand, pushing the boundaries of creativity and innovation. From awe-inspiring bio-prints to groundbreaking uses in sustainable manufacturing, the future is being layered one print at a time. Keep your eyes peeled and your imaginations churning, because the next big shift might just be a filament away. So, whether you’re a tech enthusiast, an inventive hobbyist, or a curious newcomer, dive into the world of 3D printing and watch as your wildest ideas take shape. Happy printing!