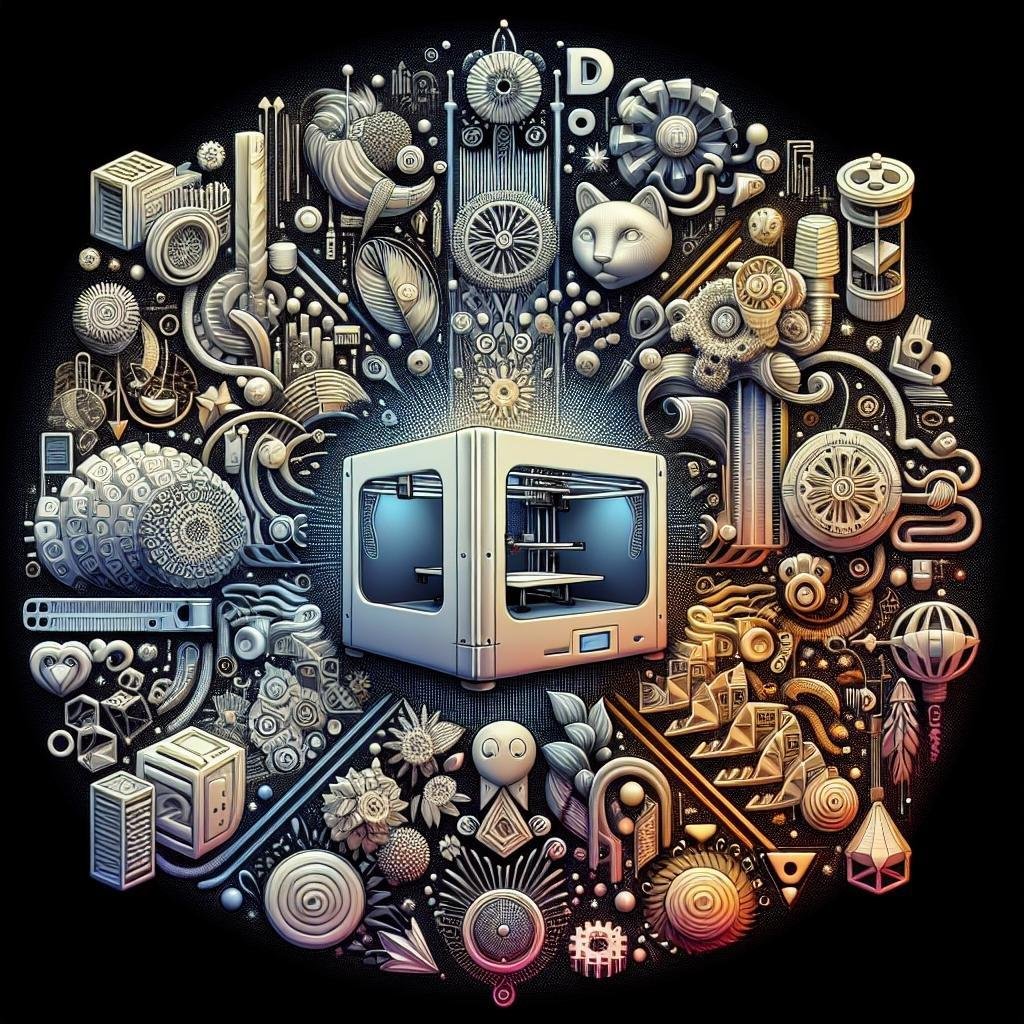

In a world where imagination knows no bounds, 3D printing stands at the intersection of innovation and creativity, reshaping the way we think about production and design. Once a niche hobby reserved for tech enthusiasts and the occasional inventor, 3D printing has burst into the mainstream, captivating the attention of industries and hobbyists alike. This year, as the technology continues to evolve and inspire, it has taken center stage, unveiling a tapestry of exciting trends that are transforming the fabric of our everyday lives. From lasting solutions to breath-taking artistic creations, let’s embark on a engaging journey through the top 10 3D printing trends of the year, where the only limit is the sky—or perhaps, your imagination!

Revolutionizing Industries with 3D Printing Brilliance

- Mass Customization: The melding of personalized design and mass production has taken center stage as 3D printing empowers industries to offer tailor-made products with unparalleled precision. Fashion brands are sculpting bespoke footwear that aligns with individual foot contour, while the healthcare sector is crafting patient-specific prosthetics that ensure both comfort and effectiveness. This harmonious blend between mass availability and uniqueness supports a vibrant consumer experience, transforming how products are imagined and delivered.

- Sustainable Material Innovations: With a growing focus on eco-friendliness, researchers and companies are continually developing biodegradable materials that reduce the environmental footprint. From recycled plastics to plant-based polymers, these innovative materials not only bolster ecological conservation but also maintain strength and versatility across applications.Embracing sustainability, the newfound capabilities facilitate a greener production process while capturing the imagination of creators seeking conscious alternatives.

| Industry | Application | Impact |

|---|---|---|

| Aerospace | Lightweight Parts | Fuel Efficiency |

| Healthcare | Custom implants | Improved Patient Outcomes |

| Fashion | Custom Apparel | Unique Designs |

Automation Synergy is fostering unprecedented speed and accuracy within the manufacturing domain. Advanced printers, paired with AI and robotics, are automating processes, drastically cutting down production times and minimizing human error. By seamlessly embedding machine learning, the technology intuitively adapts to optimize designs and materials, heralding an era where creation occurs at the pace of thought.Meanwhile, the construction industry is erecting structures at a breath-taking pace, with 3D printed houses vastly reducing labor costs and time frames.This industry-wide renaissance is paving the way for communities around the globe to access affordable,efficient,and resilient infrastructure solutions.

Innovative Materials Shaping the Future of Fabrication

In recent times, the field of 3D printing has been revolutionized by innovative materials that open new possibilities across various industries. These cutting-edge substances are not merely pushing the boundaries of what’s possible but are also redefining how we perceive manufacturing and craftsmanship. From biodegradable plastics to conductive filaments, the versatility of materials available today empowers creators to experiment and innovate like never before.For instance, biodegradable materials are notably promising for sustainable manufacturing processes, providing ecologically responsible alternatives to traditional, petroleum-based plastics.Similarly, conductive filaments are enhancing the realm of wearable technology, integrating wiring directly into fabric-like surfaces, which delights both tech enthusiasts and fashion iconoclasts.

The diversity of materials also includes things like food-grade composites and metal-infused plastics, sparking transformation in culinary arts and heavy industries alike. While metal-infused plastics enable intricate designs with the durability of metal,food-grade composites contribute to customized culinary experiences,leading to unique,three-dimensional food designs that alter the dining landscape. These materials can serve as the building blocks for everything from luxury dining experiences to complex engineering structures. Below, you can find a concise table listing some remarkable materials and their applications:

| Material Type | Common Applications |

|---|---|

| Biodegradable plastics | Eco-friendly Packaging |

| Conductive Filaments | Wearable Tech |

| Food-grade Composites | 3D Printed Foods |

| Metal-infused Plastics | Automotive Parts |

Navigating the Eco-friendly Path in additive Manufacturing

Adopting eco-friendly practices in 3D printing isn’t just a trend—it’s becoming an essential shift in the industry. Sustainable materials are leading the charge, with a focus on biodegradable and recycled filaments. Not only do these materials reduce the environmental footprint, they also open up an avenue for innovators to experiment with new textures and strengths. On a larger scale, companies are now prioritizing energy-efficient printing processes. Eco-conscious manufacturers are implementing machines that consume less power, helping to minimize operational costs while supporting environmental goals.These efforts aren’t limited to production; they’re expanding to the supply chain, reducing emissions, and promoting responsible sourcing of raw materials. By focusing on sustainability, the industry challenges companies to continuously push the boundaries of what’s possible.

- Biodegradable Filaments

- Recycling Initiatives

- Energy-Efficient Machines

Companies are also tapping into the potential for waste reduction by optimizing design and manufacturing. By leveraging software capable of creating precise geometries, additive manufacturing minimizes excess material use. Trial and error are less of a waste when designs are perfected digitally before production begins. A noteworthy trend is the increase in collaborative movements, where innovators and organizations partner to share best practices, advancing green technologies across sectors. This harmony of innovation and collaboration is setting a powerful precedent, one where profits and the planet can coexist.Energy and waste-consumption tables are becoming vital, showcasing not just what is feasible, but what is necessary for a circular, sustainable economy.

| Aspect | Description |

|---|---|

| Materials | Biodegradable, Recycled |

| Processes | Energy Efficient, minimal Waste |

| Collaboration | Global Innovation Alliances |

Mastering Customization: Practical Tips for Tailored Designs

When it comes to crafting unique and personalized creations with 3D printing, the key lies in understanding the possibilities at your fingertips. One essential approach is to experiment with materials beyond the typical PLA or ABS.Flexible filaments,wood-infused composites,and metal-infused materials offer exciting alternatives that can radically change the aesthetic and functional aspects of your projects. Furthermore, tapping into the potential of multi-color and multi-material printing will allow you to blend textures and colors seamlessly, elevating the visual and tactile appeal of your design.It’s all about challenging traditional boundaries to bring your ideas to life.

Beyond material choices, honing the precision of your designs can substantially enhance customization. Tools and software that enable parametric design allow for the dynamic adjustment of specific features, tailoring them to individual preferences or specific requirements.Utilizing such capabilities, designers can create collections that are designed to be modified easily, ensuring broader appeal and personal nuances. Consider integrating the following strategies to push your designs to the next level:

- Leverage online forums to gather insights and feedback from fellow printing enthusiasts.

- Employ batch printing techniques to experiment rapidly with varied designs and configurations.

- Maintain a detailed project journal for tracking iterations and optimizations.

Adopting these practices not only sharpens the customization process but also strengthens the connection between creator and creation, paving the way for truly unique 3D printed wonders.

Q&A

article Title: Unveiling the Future: Top 10 3D Printing Trends of the Year

Q&A Section

Q1: What makes 3D printing so revolutionary in the current year compared to previous years?

A1: Ah, the winds of innovation have blown favorably for 3D printing this year! The technology has not only matured but also diversified, making it more accessible than ever. With reduced costs and enhanced capabilities,from complex bio-printing to full-scale construction,3D printing is turning unachievable ideas into touchable reality.

Q2: How is sustainability being addressed in 3D printing trends this year?

A2: Sustainability is trending hotter than a filament extruder nozzle! Many companies are prioritizing eco-friendly materials and processes. This includes using recycled plastics and biodegradable materials within 3D printing. The beauty is that this tech not only minimizes waste by printing precisely what’s needed but is also exploring ways to use renewable energy sources.

Q3: What are the most exciting materials popping up in 3D printing?

A3: Materials this year are as exciting as a color palette in an artist’s studio. We’re seeing a surge in the use of advanced composites, conductive materials for electronics, and even edible substances for innovative cuisine creations. Then there are the cutting-edge newcomers like graphene-infused filaments and biodegradable polymers leading the charge.

Q4: Is AI being used in 3D printing, and if so, how?

A4: Absolutely, AI is the brain behind the brawn! Artificial intelligence is supercharging 3D printing with more efficient design processes, predictive maintenance, and adaptive learning systems. This smart tech is enabling printers to optimize prints in real-time, ensuring error-free and high-quality outputs.

Q5: Are there any notable breakthroughs in medical 3D printing this year?

A5: The medical field is experiencing a renaissance with 3D printing this year! From printing customized prosthetics and implants to even bio-printing tissues and organs, the healthcare applications seem boundless. It’s not just innovation; it’s revolutionizing patient care by enhancing precision, personalization, and cost-effectiveness.

Q6: How has 3D printing affected the manufacturing industry this year?

A6: 3D printing has spun the manufacturing industry on its axis! Known as additive manufacturing, it’s reducing lead times and costs while enabling unparalleled customization and on-demand production capabilities. This shift is not only for prototyping but is also setting the stage for direct production models.

Q7: What’s the buzz around 3D printing in the food industry?

A7: The culinary world is being delightfully disrupted by 3D printing. Imagine creating intricate chocolates or custom-shaped pizzas with the push of a button! This year, 3D printing is expanding chefs’ creativity while addressing food sustainability, making it a gourmet game-changer.

Q8: Is there a focus on education within 3D printing this year?

A8: Schools and universities are adopting 3D printing like never before! It’s not just about making cool models; it’s a powerful tool for hands-on STEAM education. Students are learning about design, engineering, and problem-solving in creative ways, preparing them for the future.

Q9: What future trends can we expect to see emerge from today’s developments?

A9: Fasten your seatbelt; the journey is thrilling! Looking into the crystal ball reveals trends like the widespread adoption of decentralized manufacturing, further advances in bio-printing, enhanced multi-material printing, and even the advent of consumer 3D printing networks for everyday items. Onward to new possibilities!

Q10: How can someone get started with 3D printing today?

A10: Embarking on a 3D printing adventure is easier than ever! Start by researching affordable starter kits and online communities. There are loads of free resources, tutorials, and design software available to tinker with.Dive in, experiment, and watch your ideas take shape before your eyes. Welcome to the world of makers!

The Way Forward

As we wrap up our exploration of the top 10 3D printing trends of the year, it’s clear that the landscape of innovation is more dynamic than ever. From cutting-edge materials to breakthroughs in sustainability, 3D printing is not just reshaping industries—it’s reimagining possibilities. Whether you’re a hobbyist getting your hands on the latest tech or a professional trailblazer pushing the boundaries, these trends offer a thrilling glimpse into the future. So, let’s keep our printers primed and creativity flowing, as next year’s horizon is full of even more remarkable discoveries. Until next time, keep dreaming, designing, and transforming the way we create our world!