In the bustling realm of 3D printing,where innovation and creativity intertwine to produce wonders at the click of a button,lies an intriguing subset of materials that promise to push the boundaries of your imagination—flexible filaments. With their unique ability to bend, stretch, and conform, these materials transform the rigid world of 3D structures into a playground of possibilities. Whether you’re molding a custom-fit phone case or concocting a one-of-a-kind wearable piece of art, harnessing the power of flexible filaments can elevate your creations to new levels of dynamism and functionality. Join us as we dive into the captivating world of flexible filaments, sharing tips and tricks to ensure your prints are as seamless and resilient as your creativity demands. Welcome to a journey where flexibility is the new frontier, and your 3D printer is the gateway!

Mastering Stability in Your 3D Prints: Handling Flexibility with Precision

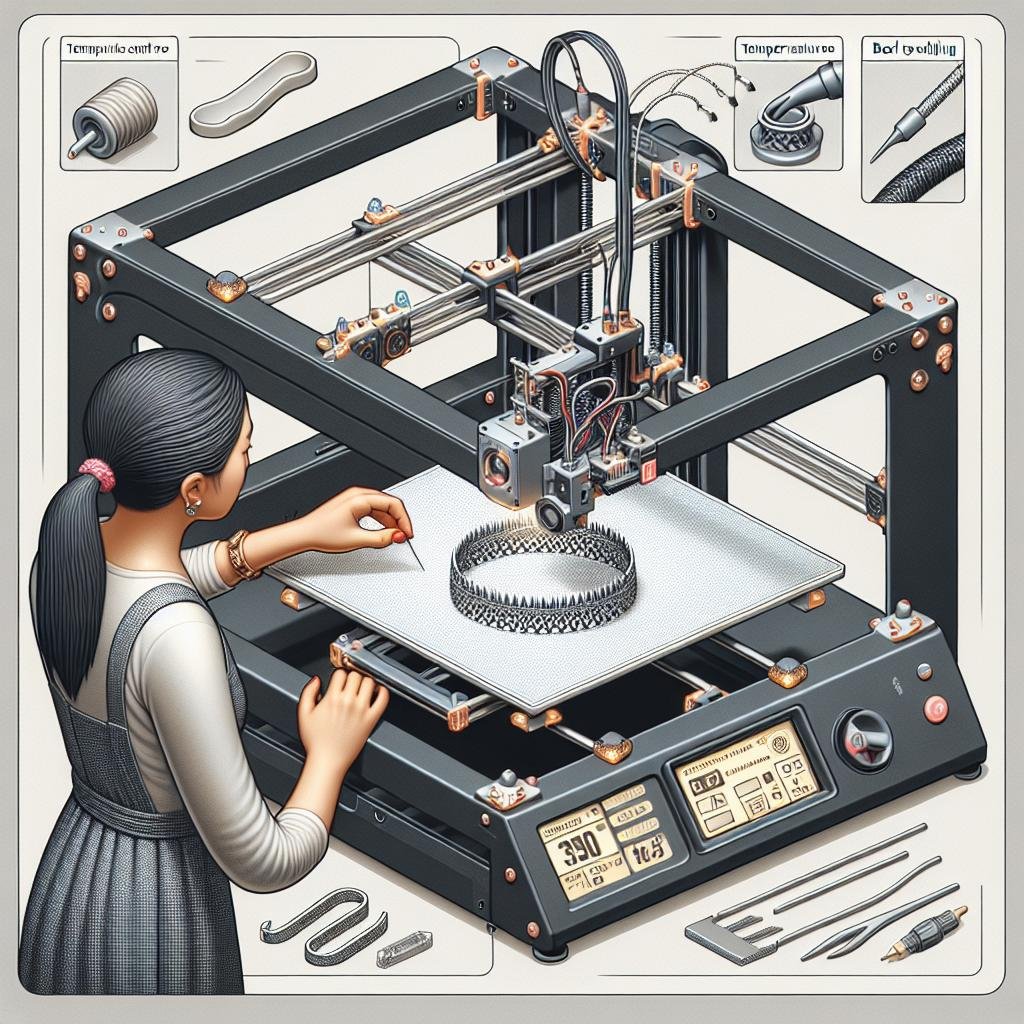

When it comes to tackling the challenges of 3D printing with flexible filaments, precision is key.Start by dialing in your printer settings. Adjust the temperature carefully, as flexible filaments like TPU and TPE are sensitive to temperature fluctuations. A good starting point is to set your nozzle temperature to around 200-240°C, but always check the filament manufacturer’s recommendations. Slowing down the print speed is another essential tweak; aim for 20-30 mm/s to avoid filament tangles and ensure smooth layering. Don’t forget to tweak the retraction settings to minimize stringing—experiment with lower retraction distances and speeds to find that sweet spot.

Consider upgrading your printer’s hardware to improve handling of flexible materials.A direct-drive extruder can provide more consistent tension and better control over the filament. Enabling cooling fans can also enhance print stability but use them sparingly to avoid part warping. Investing in a flexible build plate can make removing prints a breeze, minimizing potential damage to both your object and the setup. Additionally, take a look at the crucial factors when selecting flexible filaments:

| filament Aspect | Desirable Quality |

|---|---|

| shore Hardness | 70A – 95A for better flexibility |

| Diameter Consistency | ± 0.05 mm for smoother feeding |

| Moisture Absorption | Low to reduce printing issues |

Experimentation is your best friend here. Use a process of trial and error with various types of flexible filaments to find what combinations of temperature,speed,and retraction settings work best for your model’s complexity. Happy printing!

Taming the Stretch: Adjusting Printer Settings for Optimal Results

Diving into printer settings can feel intimidating, especially when dealing with the unique quirks of flexible filaments. Begin with slowing down the print speed, as flexible materials benefit from a more leisurely approach. This reduces the chance of filament kinking, a common hurdle with these forgiving yet tricky materials. Another key setting is the retraction distance, which minimizes the occurrence of stringing—an annoying webbing effect that can mar the surface of your prints. Minimize retraction to allow the filament to seamlessly flow and avoid creating awkward gaps.

To further enhance print quality, you might want to explore the use of a direct drive extruder, which provides better control over filament feeding. Consider the following additional adjustments:

- Hotend temperature: Increase slightly, just enough to encourage smooth extrusion.

- Ensure a clean nozzle: Residue can obstruct smooth flow, causing errors.

- Cooling settings: Use more directed cooling to avoid warping.

| Adjustment | Recommendation |

|---|---|

| Print Speed | 30-40 mm/s |

| Retract Distance | 1-2 mm maximum |

| Hotend Temperature | 210-230°C |

Building a Strong Foundation: Essentials of Bed Adhesion with Flexible Filaments

When it comes to printing with flexible filaments, ensuring your print adheres to the bed can make or break your project. A well-prepared print bed is your first step toward achieving successful prints. Here are some essentials to consider:

- Bed Temperature: Flexible filaments tend to require specific bed temperatures to ensure proper adhesion. Verify the optimal temperature setting for your particular filament to prevent warping or detachment.

- Surface Type: Certain surface types, like glass or a PEI sheet, work better with flexible materials. Experiment to find the one that gives you the best adherence.

- Adhesive Aids: Utilizing adhesives such as glue sticks, hair spray, or painter’s tape can substantially enhance the adherence of your prints, especially on tricky surfaces.

Understanding the nuances of flexible materials can immensely improve your printing experience. A creative addition to your process is maintaining the perfect nozzle height. Too close, and the nozzle might end up dragging; too far, and the model might not stick. Here’s a fast reference to guide you:

| Action | Outcome |

|---|---|

| Adjust Nozzle Height | Prevents dragging, ensures smooth layers |

| Level the Bed | Promotes even layering, reduces errors |

By paying attention to these foundational elements, you can transform your 3D printing projects with flexible filaments from just another task to a captivating craft.

Materials Matter: Choosing the Right Flexible Filament for Your Project

When diving into the world of flexible filaments for 3D printing,it’s essential to recognize their unique properties and how they align with the demands of your project. Thermoplastic Elastomers (TPE) and Thermoplastic Polyurethane (TPU) are among the most popular choices due to their elasticity and robustness. They each bring different benefits to the table. Here’s a quick rundown:

| Type | key Feature | Best Used For |

|---|---|---|

| TPE | Highly flexible | Wearables, phone cases |

| TPU | Resilient and durable | Car parts, gaskets |

Choosing the right filament involves more than just material properties. You’ll want to consider the Shore Hardness, which indicates how soft or hard your printed piece will be. Lower Shore values mean softer, more elastic prints, ideal for intricate details or custom grips. Here are a few things to keep in mind when selecting your filament:

- Compatibility with your printer: Not all printers handle flexible materials well; check if you need a direct drive extruder.

- Speed and temperature settings: Flexible filaments often require slower print speeds and precise temperature control.

- Project requirements: Consider mechanical stress, flexibility needs, and environmental conditions.

Approach your selection like a tailor choosing fabric — the perfect filament is key to a functional, enduring, and aesthetically pleasing creation.

Q&A

Article Title: Mastering the Art of Flex: Tips for 3D Printing with Flexible filaments

Q1: What makes flexible filaments different from standard filaments like PLA or ABS?

A1: Great question! The magic of flexible filaments lies in their elasticity. Unlike rigid filaments such as PLA or ABS, flexible filaments like TPU or TPE can stretch and bend without breaking.This makes them perfect for projects needing a bit of give, like phone cases or custom-fit wearables. Imagine having your very own stretch Armstrong—now you can print it!

Q2: Are there any special printer settings I need to tweak for flexible filaments?

A2: Absolutely! Flexibility requires a gentle hand, or in this case, a gentle nozzle.Start by lowering your print speed to reduce strain on the filament. It’s like walking instead of running—slow and steady wins the race! Set the retraction speed lower and shorten the distance to avoid clogging. Keep your print bed warm (around 40-60°C), and don’t forget to double-check that your filament path is as smooth as a ballroom dance floor.

Q3: Do I need any specific 3D printer to work with flexible filaments?

A3: while any printer can potentially work with flexible filaments, direct drive extruders work best.Why, you ask? They minimize the distance the filament travels from the extruder gear to the nozzle. Think of it like a short, sweet commute rather of a long, winding road. Bowden setups can be trickier but not impossible once you master the art of tinkering!

Q4: Why is bed adhesion such a big deal with flexible filaments?

A4: Imagine trying to build a house on an ice skating rink—it’s not ideal! Similarly, flexible filaments need a good grip on the print bed to keep from peeling or warping. Use a quality adhesive like a glue stick or painter’s tape, and consider adding a brim for extra sticking power. The better the grip, the smoother the final product!

Q5: Any pro tips for avoiding common pitfalls with flexible filaments?

A5: Without a doubt! First, keep an eye on your filament storage; hygroscopic materials like flexible filaments love absorbing moisture. Store them in a dry place or use a filament dryer. Second, patience is key—flexible filaments may require a few trial runs to find the perfect settings. Lastly, celebrate small successes. Each twist, bend, and stretch is a step toward becoming a flexible filament maestro!

Q6: What exciting projects can I try with flexible filaments?

A6: Oh, the possibilities are as vast as your imagination! From stress balls and ergonomic grips to cosplay costumes and custom gaskets, flexible filaments open up a world of creative potential. Feeling adventurous? Try designing a pair of agreeable, personalized insoles or test the limits with a flexible drone frame! Each project will teach you something new and might just bend your mind in the process.

Feel free to dive into the world of flexible filaments, where creativity knows no bounds! Happy Printing!

to sum up

As we wrap up our journey through the world of 3D printing with flexible filaments, its clear that this versatile material can truly stretch the limits of your creativity. Whether you’re fashioning a custom phone case, crafting a pair of stylish yet comfortable shoes, or designing the next innovative gadget, these tips are sure to give your projects the flexibility they deserve. Remember, patience and practise are your greatest allies in mastering this bendy medium. So,keep experimenting,keep learning,and most importantly,keep printing. Before long, you’ll be bending the rules and reshaping the possibilities of your 3D creations. Until next time, may your prints be as flexible as your imagination!