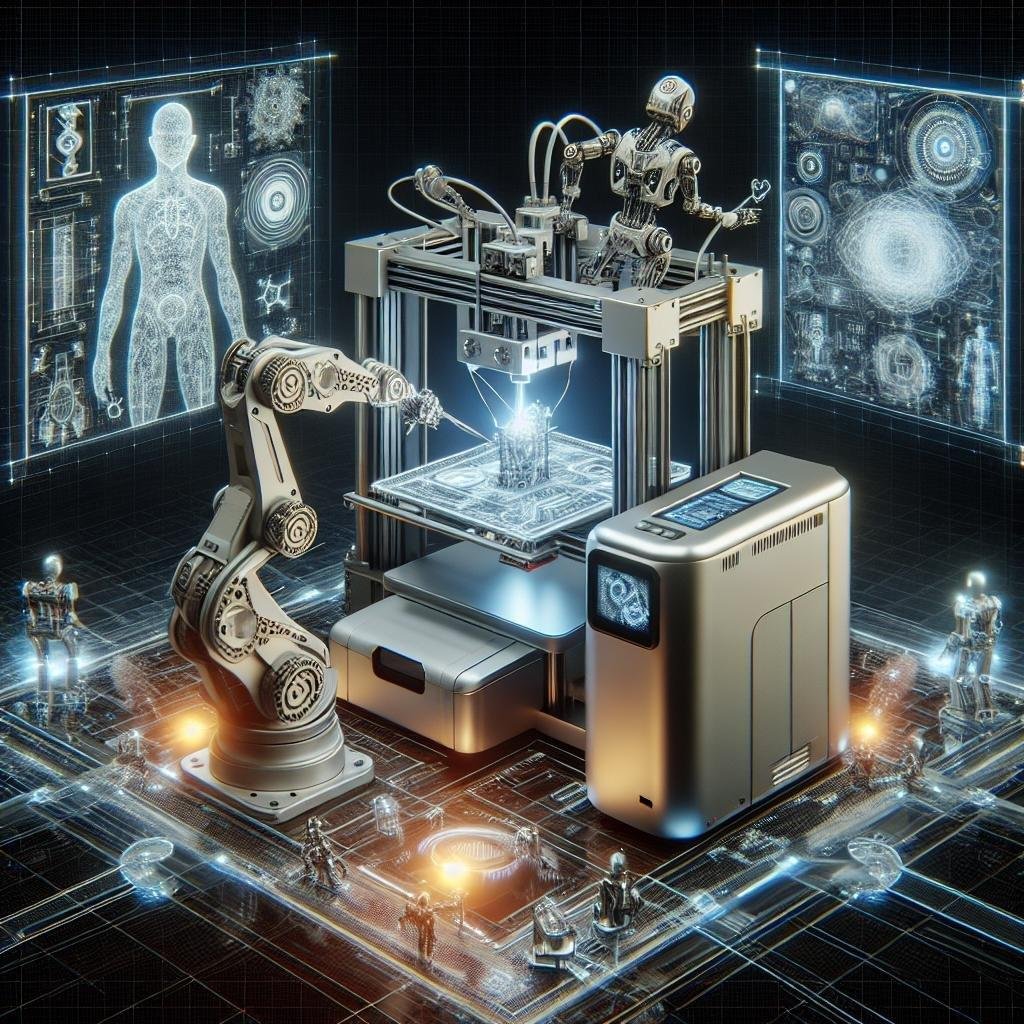

In a world where technology is perpetually pushing the boundaries of what’s possible, a interesting convergence is taking place: the union of 3D printing and robotics.Imagine a realm where creativity knows no limits and machines build themselves, component by component, with the grace of an artist and the precision of a craftsman. This is not science fiction; this is the exhilarating reality unfolding at the intersection of two revolutionary fields.As 3D printing breathes life into digital designs and robotics awakens them into motion, we are on the cusp of a technological renaissance.This confluence promises not just to reshape industries but to redefine our imaginations. Welcome to the captivating dance between the makers and the movers, where each innovation paves the way for a new dimension of possibility. Join us as we explore how these technological marvels are coming together to transform the way we create,build,and think.

3D Printing and Robotics: Crafting a Future of Limitless Possibilities

As technology continues to advance, the marriage of 3D printing and robotics is crafting a horizon brimming with innovation and possibilities. These two cutting-edge technologies, when intertwined, create a symphony of precision and adaptability that is revolutionizing various industries. Imagine automated robots equipped with 3D printers, producing intricate components on-the-fly, reducing waste, and optimizing design like never before. Picture a filament-fed robotic arm sculpting bespoke prosthetics tailored to individual needs, or autonomous drones repairing infrastructure with seamless efficiency. The agility of robotics, paired with the versatility of 3D printing, forms a partnership where creativity knows no bounds.

The benefits of integrating these technologies are manifold, ranging from increased efficiency to transformative ecological impacts. A few key advantages include:

- Cost Efficiency: Minimizing material waste and energy consumption.

- Customization: Tailoring products to specific user requirements with ease.

- Accessibility: Bringing manufacturing capabilities to remote or underserved locations.

Industries like healthcare, aerospace, and construction are reaping the benefits, making strides towards creating a enduring future. With ongoing research and development, we stand on the precipice of a new era where the onyl limitation is our creativity.

| Applications | Industry |

|---|---|

| Prosthetic Development | Healthcare |

| Automated Assembly | Manufacturing |

| Aerial Inspection & Repair | Infrastructure |

From Blueprint to Reality: How 3D Printing is Revolutionizing Robotics Design

In recent years, advances in 3D printing technology have redefined traditional boundaries in robotic design, bringing once-impossible concepts to life.The ease with which a mere software blueprint can translate into a tactile robot through 3D printing bridges the gap between conceptual and practical domains. Key advantages of this technology include:

- Rapid Prototyping: Designers can quickly convert digital designs into physical models, allowing for fast iterations and immediate testing.

- Customization and Complexity: Intricate geometries, which were once impractical or expensive to achieve using conventional methods, can now be effortlessly created.

- Cost Efficiency: Material waste is minimized, and the need for expensive tooling is eliminated, making the design process more affordable.

Roboticists are thrilled about how these capabilities enhance efficiency and foster innovation. A great example is the integration of modular components, which has become seamless, thanks to 3D printing.Engineers can fabricate parts that fit together like puzzle pieces, allowing robots to evolve and adapt for various tasks. To illustrate this transformation:

| Aspect | Traditional Methods | 3D Printing |

|---|---|---|

| Component Turnaround | Weeks | Hours |

| Design Flexibility | Restricted | Highly Flexible |

| Cost Per Prototype | High | Low |

This fusion of 3D printing with robotics not only accelerates development but also emboldens the imagination, by allowing creators to explore new design paradigms without the fear of costly experiments. The world of robotics stands on the precipice of unprecedented innovation,catalyzed by these technological advancements.

Amplifying Efficiency: The Role of 3D Printing in Streamlining Robotic Manufacturing

The synergy of 3D printing and robotics is a game-changer in modern manufacturing, creating pathways for unprecedented efficiency. By enabling the rapid prototyping of parts and components,3D printing significantly reduces lead times and facilitates swift iterations. This flexibility allows manufacturers to adapt quickly to design changes and demand fluctuations, keeping the production line agile. With fewer constraints in component design, robotics can be customized to perform highly specialized tasks, enhancing their capability and versatility.

Integrating 3D printing into robotic manufacturing not only streamlines the production process but also contributes to sustainability by minimizing waste and optimizing resource use. The ability to produce only what’s needed, precisely when it’s needed, aligns with lean manufacturing principles. Key benefits of this integration include:

- Cost efficiency: By reducing material waste and speeding up the design-to-production cycle.

- customization: Tailoring specific parts for unique robotic functionalities.

- Innovation: Encouraging experimental designs and rapid market introduction.

| Benefit | Impact |

|---|---|

| Rapid Prototyping | Decreases time from design to production |

| Reduced Waste | Optimizes material use |

| enhanced Customization | Allows for innovative request designs |

embrace the Tech Duo: Guidelines for Integrating 3D Printing into Robotics Development

Diving into the collaboration between 3D printing and robotics unveils a symphony of opportunities, allowing for unprecedented creative freedom in prototyping and production. The first step is understanding the compatibility and potential synergy between these two technologies. By utilizing 3D printing, you can produce custom, lightweight components swiftly, frequently enough at a fraction of the traditional manufacturing costs. This flexibility not only speeds up the innovation cycle but also introduces a new level of artistry in design. Key considerations include selecting materials that match the operational needs of your robot and ensuring dimensional accuracy.The beauty of this integration is that it doesn’t demand a complete redesign of current systems; rather, it encourages adaptive evolution.

To optimize this tech duo, adhere to these core guidelines:

- Design with Modularity in Mind: Create components that can be easily upgraded or replaced.

- Leverage Customization: Use 3D printing’s unique ability to tailor forms to the specific requirements of your robotics project.

- Choose the Right Material: Balance functionality with strength and weight, selecting polymers, composites, or metals as needed.

- Iterate Rapidly: Embrace an iterative prototyping approach to fine-tune designs, saving both time and money.

| Benefit | Description |

|---|---|

| Cost Efficiency | Reduced production costs with minimal material waste. |

| Speed | Faster prototyping allows for quicker project rollouts. |

| Flexibility | Design freedom enables varying levels of customization. |

Each layer of filament, each motorized function, tells a story of innovation. For every robotic creation lies a custom-designed support structure—proof that when integrated thoughtfully, 3D printing can transform the robotics landscape. Next, let’s reinforce our understanding of testing and validation to ensure robustness and reliability in our developments.

Q&A

Q&A: The Intersection of 3D Printing and Robotics

Q: What exactly is the intersection of 3D printing and robotics?

A: Imagine a world where robots can not only perform complex tasks but also evolve their own designs and tools using 3D printers. This intersection is precisely where the innovative capabilities of 3D printing meet the clever functionalities of robotics. It’s like a creative dance where robots can 3D print parts to repair themselves or customize their accessories on the go!

Q: How are these technologies currently being integrated?

A: Currently,3D printing is predominantly used to create robotic components,from intricate joint mechanisms to customizable grippers. Engineers design parts specifically for robotic functions and print them using durable materials. Moreover, some advanced robots are already equipped with built-in 3D printers, allowing them to fabricate new components as needed, almost like a high-tech, self-sustaining toolbox!

Q: What are some real-world applications?

A: The possibilities are endless! In healthcare, researchers are developing robotic prosthetics that are tailored to individual patients using 3D printing, ensuring a perfect fit and unique functionality. In the aerospace industry,robotic drones equipped with 3D printers can create parts mid-flight for swift repairs or adaptations. It’s a bit like having your very own superhero maintenance crew in the sky!

Q: How does this intersection impact sustainability?

A: This collaboration can greatly enhance sustainability efforts. 3D printing minimizes waste by using only the necessary materials, while robots can efficiently assemble these parts with precision. With robots being able to repair and recycle their own components, we could perhaps reduce the technological waste that frequently enough plagues our environment.It’s a green tech dream team!

Q: What challenges do these technologies face when working together?

A: One of the main challenges is material compatibility.Finding materials that are both robust enough for robotic operations and suitable for 3D printing can be tricky. Additionally, the software integration required to coordinate between complex robotic systems and precise printing operations is an ongoing puzzle. But tech visionaries are on the case!

Q: Are there any exciting future prospects we should be aware of?

A: Absolutely! On the horizon are advanced manufacturing facilities where robots could autonomously create entire systems or infrastructures using 3D printing. Imagine exploring Mars with robots that build our habitats from local resources! We’re witnessing the dawn of a new era in adaptable, intelligent manufacturing, and it’s just getting started.Q: How can I get involved or learn more about this field?

A: Dive into online courses focusing on robotics and 3D printing, join community maker spaces, or participate in forums and competitions. It’s a field brimming with creativity and innovation, welcoming both seasoned engineers and curious newbies.Whether you’re looking to contribute to cutting-edge research or embark on DIY projects, the gate to this industrial revolution is wide open!

To Wrap It Up

As we reach the end of our exploration into the fascinating world where 3D printing meets robotics, we’re left with a vision of the future that glimmers with possibility. This intersection is not just a crossing of technologies; it’s a vibrant meeting place where innovation knows no bounds.From crafting intricate machinery to sparking a new wave of sustainable practices, these two fields are dynamically reshaping industries and daily life. As we forge ahead, let us embrace the spirit of creativity and collaboration inherent in this blend, ready to tackle challenges and surprise ourselves with the wonders yet to be discovered. Whether you’re an engineer, a hobbyist, or simply an enthusiast, the journey of melding 3D printing with robotics is only just beginning. Together, let’s keep pushing the boundaries of what’s possible, one layer and one robot at a time. Until next time, imagine boldly and create passionately!