In this exciting article, you will discover the latest trends and innovations shaping the future of 3D printing. From advancements in materials and designs to the endless possibilities for industries like healthcare, aerospace, and architecture, this technology is revolutionizing the way we create and manufacture objects. Get ready to explore the limitless potential of 3D printing and uncover the groundbreaking developments that are set to transform various sectors.

Advancements in Materials

Resins

In the world of 3D printing, the choice of materials plays a crucial role in determining the quality and properties of the printed object. Resins have seen significant advancements, offering a wide range of possibilities for various applications. From tough and durable resins suitable for engineering prototypes to flexible and transparent resins for creating intricate designs, the options are expanding. With improved resin formulations, 3D printing is now capable of producing high-quality, functional parts with exceptional detail and surface finish.

Metals

The ability to print with metals has revolutionized the manufacturing industry. With advancements in metal 3D printing technologies, complex and intricate metal parts can now be produced with precision. Metal powders such as titanium, aluminum, and stainless steel are used as the raw material, and through processes such as selective laser melting and electron beam melting, the metal particles are fused together to create solid, fully functional components. This has opened up a world of possibilities in aerospace, automotive, and even medical industries, where the strength and durability of metal parts are essential.

Biological Materials

One of the most exciting and promising areas in 3D printing is the use of biological materials. By incorporating living cells and biomaterials, researchers are exploring the potential of printing organs, tissues, and even human implants. This field of bioprinting holds immense potential for revolutionizing medicine, allowing for personalized and tailored solutions for patients. Through the precise layering of bioinks and the use of specialized printers, researchers are inching closer to creating functional organs that can be transplanted into patients in need.

Increased Speed and Efficiency

Improved Printing Processes

3D printing processes have come a long way since their inception, and significant improvements have been made to enhance the overall printing experience. Innovations such as continuous printing, where the printer can continuously produce objects, have resulted in significant time savings. Additionally, major strides have been made in reducing the need for supports during the printing process, resulting in more efficient material utilization and less time spent on post-processing.

Faster Printing Times

Advancements in hardware and software have led to faster 3D printing times. With the development of high-speed printing technologies, such as parallel printing and multi-nozzle systems, objects can now be printed in a fraction of the time it used to take. This not only improves productivity but also allows for rapid prototyping and on-demand manufacturing, enabling companies to bring products to market faster.

Enhanced Precision

Precision is a critical factor in 3D printing, especially when it comes to producing intricate and detailed objects. Recent advancements in printer technology and software algorithms have made it possible to achieve higher levels of precision. This means that even the most complex designs can be accurately translated into physical objects with minimal deviation. Enhanced precision opens up new possibilities in industries such as aerospace, where intricate and lightweight components are crucial for optimal performance.

Expanded Range of Applications

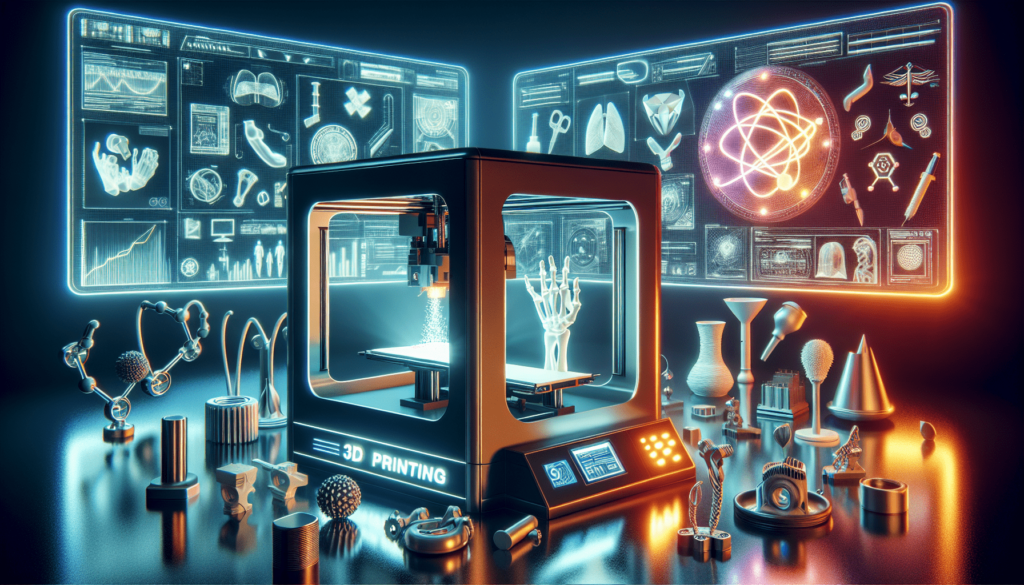

Medicine

The field of medicine has been revolutionized by 3D printing. From creating personalized prosthetics to printing complex anatomical models for surgical planning, 3D printing has become an indispensable tool in healthcare. Customized implants tailored to an individual’s anatomical structure can now be produced, leading to better patient outcomes. Additionally, the ability to print pharmaceuticals and drug delivery systems opens up new avenues for personalized medicine and improved treatment options.

Architecture

Architects and designers are embracing 3D printing to push the boundaries of traditional construction methods. By using large-scale 3D printers, it is now possible to create intricate and complex architectural structures with ease. 3D printing allows for greater design freedom, enabling unique and innovative designs that were previously difficult or costly to achieve. This technology also facilitates sustainable construction practices by optimizing material usage and reducing waste.

Automotive Industry

The automotive industry has embraced 3D printing for a variety of applications, including prototyping, tooling, and even end-use parts. With the ability to produce complex geometries and lightweight components, 3D printing offers significant advantages in terms of vehicle performance and fuel efficiency. Additionally, 3D printing enables customization and personalization of interior components, allowing car manufacturers to cater to the specific preferences of their customers.

Fashion

The intersection of technology and fashion has led to exciting developments in the world of 3D printing. Designers are using 3D printers to create intricate and avant-garde fashion pieces that push the boundaries of traditional garment construction. 3D-printed textiles, accessories, and even entire garments are becoming more prevalent in the fashion industry. The ability to produce customized and tailored fashion items offers new opportunities for designers to create unique pieces that reflect individual style and expression.

Food

The realm of 3D printing has expanded to include the production of food. With specialized food printers, it is now possible to create intricate and visually appealing dishes. 3D food printers can precisely deposit layers of edible materials, allowing for the creation of complex and artistic food designs. This technology has the potential to revolutionize the culinary industry, enabling customized meals tailored to individual dietary needs and preferences.

Integration of AI and Machine Learning

Smart Printers

Advancements in artificial intelligence (AI) and machine learning have made it possible to create smart printers that can optimize the printing process. These printers can analyze and adjust various parameters in real-time, resulting in improved print quality and reduced errors. Smart printers can detect and compensate for any issues that may arise during the printing process, ensuring a smooth and seamless experience. This integration of AI and machine learning not only enhances efficiency but also reduces the need for manual intervention, allowing for greater automation in the printing workflow.

Optimized Designs

AI and machine learning algorithms can also be used to optimize designs for 3D printing. By analyzing data and leveraging computational design techniques, designers can create optimized structures that maximize strength, minimize weight, and reduce material usage. This results in more efficient and cost-effective designs that are specifically tailored for the 3D printing process. Additionally, AI-powered design tools can generate complex lattice structures and geometries that would be virtually impossible to create using traditional manufacturing methods.

Automated Quality Control

Ensuring the quality of printed objects is crucial, especially in industries where safety and reliability are paramount. AI and machine learning algorithms can automate quality control processes, analyzing printed parts to detect defects or deviations from the desired specifications. This allows for real-time feedback and adjustments, significantly reducing the time and effort required for manual inspection. Automated quality control not only improves efficiency but also increases the overall reliability and consistency of 3D printed products.

Mass Customization

Tailored Consumer Products

Mass customization is a growing trend in various industries, and 3D printing plays a key role in enabling this shift towards personalized products. By leveraging the flexibility and scalability of 3D printing, companies can offer customizable consumer goods to cater to individual preferences. From personalized smartphone cases to customized jewelry, 3D printing allows for the quick and cost-effective production of unique products. This customization not only enhances the consumer experience but also fosters brand loyalty and differentiation.

Personalized Prosthetics

One of the most impactful advancements in 3D printing is the ability to create personalized prosthetics. Traditional prosthetics can be expensive and time-consuming to manufacture, often requiring manual adjustments to fit an individual’s unique body structure. With 3D printing, prosthetics can be precisely tailored to the individual, resulting in a more comfortable and functional solution. This technology has transformed the lives of countless individuals, providing them with prosthetic limbs that are not only affordable but also aesthetically pleasing.

Customized Manufacturing

3D printing has disrupted traditional manufacturing by enabling customized production on a large scale. Instead of mass-producing identical objects, manufacturers can create products based on specific customer requirements. This customization allows for greater product differentiation, increased customer satisfaction, and reduced inventory costs. For industries such as aerospace and healthcare, where each product may have unique specifications, 3D printing offers a cost-effective and efficient solution for customized manufacturing.

Sustainability and Eco-friendly Practices

Recycled Materials

Sustainability is a growing concern across industries, and 3D printing offers opportunities for more environmentally friendly practices. By using recycled materials as feedstock, 3D printing can reduce waste and minimize the reliance on virgin resources. Recycled plastics and metals can be processed into filament or powder suitable for 3D printing, offering a sustainable alternative to traditional manufacturing processes. This circular approach to material usage aligns with the principles of a circular economy, reducing the overall environmental impact of production.

Reduced Waste

Traditional manufacturing processes often generate a significant amount of waste material. 3D printing, on the other hand, is inherently more efficient in terms of material utilization. With additive manufacturing, objects are built layer by layer, only using the amount of material required. This eliminates the need for cutting or machining, reducing waste and minimizing energy consumption. By adopting 3D printing, industries can contribute to waste reduction efforts and embrace more sustainable manufacturing practices.

Bio-based Filaments

Another sustainable approach in 3D printing involves the use of bio-based filaments. These filaments are derived from renewable resources such as plant-based materials or biodegradable polymers. Bio-based filaments not only offer similar performance characteristics to their petroleum-based counterparts but also have a lower carbon footprint. By replacing traditional materials with bio-based alternatives, 3D printing can significantly reduce the environmental impact of production while maintaining the desired quality and functionality of printed objects.

Nanotechnology and 4D Printing

Nano-scale Printing

The integration of nanotechnology with 3D printing has opened up new frontiers in precision and miniaturization. Nanoscale 3D printing allows for the creation of structures with dimensions on the nanometer scale, offering unprecedented control over material properties and functionality. This technology has applications in various fields ranging from electronics and photonics to medicine and energy. Nanoscale 3D printing enables the fabrication of intricate and functional devices at a level previously considered unimaginable.

Self-assembling Structures

4D printing takes the concept of 3D printing one step further by incorporating the element of time. With 4D printing, objects can be printed with materials that have the ability to respond to external stimuli, such as temperature or humidity, and self-assemble or change shape over time. This allows for the creation of dynamic and adaptive structures that can respond to their environment. The potential applications of 4D printing are vast, ranging from self-assembling furniture to biomedical implants that can adapt to the patient’s needs over time.

Collaborative and Sharing Economy

Open-source Designs

The advent of 3D printing has brought about a culture of collaboration and sharing in the design community. Open-source designs and repositories have emerged, allowing designers to share their creations with others. This collaborative approach fosters innovation and knowledge exchange, enabling designers to build upon each other’s work and create innovative solutions. Open-source designs democratize access to 3D printing technologies and empower individuals around the world to participate in the design and manufacturing process.

Shared Printing Services

The cost of acquiring and maintaining a 3D printer can be a barrier for individuals or small businesses. Shared printing services, also known as 3D printing hubs or bureaus, have emerged to address this issue. These services allow individuals or businesses to upload their design files and have them printed by a professional service provider. Shared printing services not only provide access to 3D printing technology but also offer expertise and guidance throughout the printing process. This shared economy model promotes resource-sharing and reduces the entry barrier for individuals and businesses interested in 3D printing.

Integration with Other Technologies

Internet of Things (IoT)

The integration of 3D printing with the Internet of Things (IoT) has opened up new possibilities in terms of customization and functionality. By combining 3D printing with IoT-enabled devices, objects can be printed with embedded sensors, connectivity, and interactivity. This integration allows for the creation of smart and personalized products that can interact with their environment or provide real-time data. From smart wearables to smart home devices, the combination of 3D printing and IoT enables the development of intelligent and connected objects.

Virtual Reality (VR)

Virtual reality (VR) technology is being integrated with 3D printing to enhance the design and prototyping process. With VR, designers can immerse themselves in a virtual environment, allowing for more intuitive and immersive design experiences. By combining VR with 3D printing, prototypes can be quickly produced and evaluated in a virtual space, accelerating the design iteration process. This integration enables designers to test and refine their creations in a realistic and interactive virtual environment before committing to physical production.

Augmented Reality (AR)

Augmented reality (AR) complements 3D printing by overlaying digital information onto the physical world. By using AR-enabled devices, users can visualize and interact with 3D-printed objects in real-time. AR can provide additional contextual information about the object or enable interactive features such as animations or simulations. The integration of AR and 3D printing offers exciting possibilities, allowing for enhanced user experiences and increased functionality of printed objects.

Legal and Ethical Considerations

Intellectual Property Rights

As the field of 3D printing continues to evolve, one of the key legal and ethical considerations is intellectual property rights. With the increasing accessibility of 3D printers, there is a risk of unauthorized reproduction of copyrighted objects. Designers and companies need to be aware of the potential infringement on intellectual property rights and take appropriate measures to protect their designs. Additionally, the emergence of open-source designs raises questions about the ownership and licensing of 3D printable files. Legal frameworks need to adapt to these new challenges to ensure a fair and balanced approach to intellectual property rights in the realm of 3D printing.

Regulatory Frameworks

The rapid advancement of 3D printing technologies has resulted in a need for regulatory frameworks to address safety, quality, and ethical concerns. As 3D printers become more accessible and capable, it is crucial to establish guidelines and standards to protect consumers and ensure the quality and reliability of printed objects. Regulatory frameworks need to address issues such as material safety, product certification, and liability in case of defects or malfunctions. Balancing innovation and the safeguards necessary to protect various stakeholders is a complex task that requires collaboration among regulators, industry experts, and consumer advocates.

In conclusion, the future of 3D printing is unfolding with incredible advancements in materials, increased speed and efficiency, an expanded range of applications, integration with AI and machine learning, mass customization, sustainability and eco-friendly practices, nanotechnology, the collaborative and sharing economy, integration with other technologies, and legal and ethical considerations. The continuous development and innovation in 3D printing are set to revolutionize industries and enable new possibilities that were once unimaginable. With each stride forward, 3D printing is rapidly becoming an essential tool for designers, manufacturers, and individuals seeking to unlock the full potential of this transformative technology.