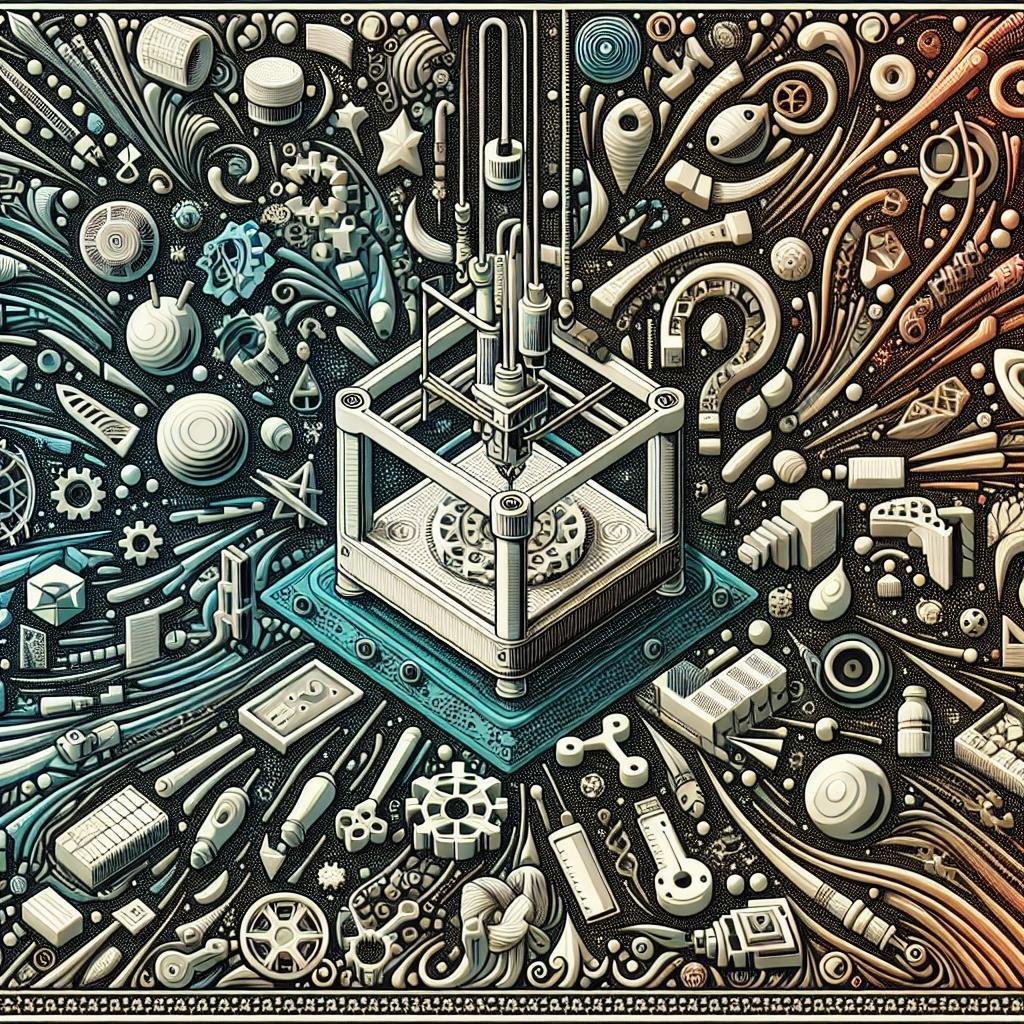

In a world where creativity meets innovation,3D printing stands as a modern marvel,transforming digital dreams into tangible realities layer by layer. This captivating technology, once a vision of the future, now sits comfortably alongside traditional craftsmanship, inviting creators of all kinds to explore its boundless potential. yet, as any artisan would tell you, the beauty of any creation lies not just in its form, but in its finish. Welcome to the exquisite realm of surface finishing techniques—the unsung heroes of 3D printing that elevate raw prints into works of art. In this article, we’ll embark on a journey through the colorful spectrum of finishing processes—from the subtle elegance of smoothing to the bold statement of texturing. Whether you’re a seasoned maker or a curious newcomer, join us as we unravel the secrets of transforming your 3D-printed masterpieces from ordinary to extraordinary, with a pleasant sprinkle of creativity and craftsmanship.

From Rough to Refined: Understanding the Basics of 3D Printing Surface Finishes

Transforming a freshly printed 3D object from its rugged birth into a polished masterpiece involves understanding the myriad of surface finishing techniques available. the initial layers, often laced with tiny ridges and imperfections, are like an artist’s rough sketch. Smoothing these surfaces is the first step, and it can be achieved through methods such as chemical baths that gently dissolve outer layers, leaving a sleek finish akin to porcelain, or through sanding, where abrasives meticulously erase any imperfections. As the layers of refinement build up,what emerges is a testimony to craftsmanship,where each step in the process adds texture,luster,or even color – promising both aesthetic appeal and functional durability.

Choosing the right finish can feel like selecting the perfect stroke of a brush for a painting. From texturizing that adds tactile intrigue to painting that provides color depth and vibrancy, the possibilities are endless. consider the type of finish that best suits your project’s purpose: does your design require a shine that catches the eye or a matte subtlety that whispers sophistication? In this artistic endeavor, materials like acrylics or metallic pigments play their part, adding a touch of elegance or a futuristic gleam. Here’s a simple table to help weigh your options:

| Material | Finish Type | considerations |

|---|---|---|

| PLA | Matte | Great for low-gloss projects |

| ABS | gloss | Ideal for vibrant, glossy finishes |

| Resin | Painted | Customization with vibrant colors |

Beyond the Print: Essential Techniques to Achieve a Professional Touch

In the world of 3D printing,achieving the desired quality often requires more than just a basic print. Once the print is complete, the journey of bringing your creation to life involves various finishing techniques that can dramatically enhance the look and feel of the final product. Here are some essential techniques to consider:

- Sanding: Smooth out those layer lines using different grits of sandpaper.

- Priming and Painting: Add color and weather-proof your creations while smoothing imperfections.

- Chemical Treatment: Use solutions like acetone for enhanced smoothness, notably for ABS parts.

- Heat Gun Smoothing: A rapid way to refine surfaces using controlled heat.

Choosing the right technique depends on the material of your print, the complexity of the design, and your project’s intended use. Let’s take a closer look:

| Material | Recommended Technique | Outcome |

|---|---|---|

| PLA | Sanding & Painting | Vibrant color and smooth feel |

| ABS | Chemical Treatment | Glossy finish, reduced layer visibility |

| PETG | Heat Gun Smoothing | Retains strength with a sleek look |

By going beyond the initial print, you not only refine the aesthetics of your 3D prints but also amplify their durability and functionality. Exploring and mastering these techniques can truly transform your creations into works of art.

Creative Texturing: Amplifying Aesthetic Appeal with Surface Treatments

3D printing opens doors to endless creative possibilities when it comes to surface finishing. By incorporating diverse texturing techniques, creators can elevate the aesthetic appeal of their projects to impressive heights. From mimicking natural elements like wood grain and stone to crafting futuristic and abstract patterns, the choices are expansive. While the layering process inherently adds texture, additional treatments can refine and redefine the tactile experiance. Using methods such as sanding, polishing, and painting, one can transform raw prints into polished, gallery-worthy pieces. Moreover, applying chemical smoothing or acetone vapor baths can result in sleek, glossy surfaces, ideal for projects aiming for a refined sheen.

Exploring surface textures isn’t limited to hands-on techniques alone. many post-processing strategies rely on technological methods to amplify aesthetic pleasure. For instance, heat treatments and UV curing enable a more controlled finish without manual intervention. Even more, inventive creators frequently enough experiment with unique solutions such as applying decals or embedding materials, thus adding layers of detail and depth. Here’s a glance at some popular treatments and their effects:

| Technique | Effect |

|---|---|

| Embossing | Adds raised patterns for tactile feedback |

| Sandblasting | Produces a matte finish with fine texture |

| Resin Coating | Creates a glossy and hardened surface |

- Mimic natural materials for authentic look and feel.

- Experiment with color accents to bring vibrancy and contrast.

- Integrate surface treatments into the design phase for best results.

Expert Tips and Tricks: Enhancing Durability and Functionality in Your 3D Prints

in the world of 3D printing, enhancing the performance of your prints frequently enough begins with the rights steps taken during the design and printing phases.But did you know the finishing techniques you apply post-production can significantly boost both durability and functionality? A little extra attention to these details could make a world of difference. Start with a gentle sanding process to smooth any rough edges or surfaces. This action not only enhances the aesthetic quality but also prepares your print for future steps. Consider incorporating vapor smoothing for filaments like ABS, as this can help in achieving a glossy, professional finish. For those prints needing extra longevity, explore chemical strengthening solutions such as using epoxy coatings or UV resin treatments, which can augment structural integrity.

- Surface Sanding: Use various grit levels to refine surfaces.

- Vapor Smoothing: Achieve sleek finishes with acetone baths.

- Chemical Strengthening: Reinforce prints with epoxy or UV resin.

Post-processing not only impacts durability but can also elevate the functionality of your prints. Incorporate heat treatment practices to relieve internal stresses common in thermoplastic materials, thereby extending their resilience under pressure. Another handy trick is aligning your layers appropriately during slicing; this can guide stress pathways in your model to enhance its strength under load. And let’s not overlook the simple, yet effective, practice of applying primer and paint layers to modify surface properties for specific applications, allowing your prints to resist elements like water, heat, or UV rays. Imagine transforming your prints with just a few additional touches of finesse—making them not only more robust but also tailored for their intended environment.

| Technique | Benefit |

|---|---|

| Sanding | Smooth finishes |

| Vapor Bath | Glossy surfaces |

| Epoxy Coating | Increased strength |

| Primer & Paint | Elements protection |

Q&A

Q: What is the importance of surface finishing in 3D printing?

A: Ah, surface finishing is like the cherry on top of your 3D printed masterpiece! While 3D printing does an impressive job of bringing digital dreams into the physical realm, surface finishing steps in to polish, shine, and truly bring those creations to life. Its the process that smooths out the layers, enhances aesthetics, and adds functionality to the final piece. Imagine crafting a stunning sculpture or a functional prototype but leaving it raw and unrefined—surface finishing ensures it’s not just seen but remembered.

Q: What are some common surface finishing techniques used in 3D printing?

A: The world of surface finishing in 3D printing is wonderfully diverse, rich with techniques to suit different materials and project needs. Some popular methods include sanding, which helps smooth out rough surfaces; vapor smoothing, often used for thermoplastics to give them a glossy finish; and painting, to add color and artistic flair. There’s also electroplating for adding metallic layers, tumbling for mass finishing, and chemical etching to get into those tiny crevices. Each technique is like a magic touch, transforming good creations into great ones.

Q: How does vapor smoothing work, and what is its benefit?

A: Vapor smoothing is truly a magician’s wand when it comes to 3D printing! It involves exposing the 3D printed object to a solvent vapor that gently melts and fuses the outer surface layers, resulting in a sleek, glass-like finish. the magic lies not only in its ability to smooth the surface but also in enhancing the strength of the piece and often making it more resistant to chemicals and moisture. Perfect for those who desire a glossy, finished appearance without compromising material integrity.

Q: Can you explain the role of painting in 3D printed surface finishing?

A: Absolutely! Painting is the artist’s palette in the world of surface finishing. It transforms a simple, monochrome 3D print into a vibrant, colorful masterpiece. Beyond mere aesthetics, painting can also offer additional protection against UV rays, moisture, and other environmental factors. The beauty of painting lies in its versatility—from airbrush techniques for smooth gradients to hand painting for intricate details, the possibilities are as limitless as the creator’s imagination.

Q: Why is it important to choose the right technique for your 3D printing project?

A: Just as a sculptor chooses the right chisel for each cut, selecting the appropriate surface finishing technique is vital for achieving the desired outcome in 3D printing. The right finish can affect not just the appearance but also the durability, usability, and tactile experience of the final product. Considerations like the material of the print, the purpose of the object, and the environmental conditions it will face all play a crucial role.Picking the proper technique is like choosing the right route on a journey—it makes all the difference in arriving exactly where you want to go.

Q: Are there any challenges associated with surface finishing in 3D printing?

A: Every rose has its thorns, and indeed, surface finishing in 3D printing has its own set of challenges. Achieving a perfect finish might require time, patience, and practice. Some techniques can be labor-intensive,and there’s always the risk of over-finishing,which could affect the part’s dimensions or performance. However, with careful planning, a steady hand, and perhaps a little trial and error, these challenges can be overcome, leading to results that are well worth the effort. after all, every journey has its hurdles, but they’re what make reaching the destination so rewarding!

The Way Forward

as we conclude our journey through the captivating world of 3D printing and its myriad surface finishing techniques, it’s clear that this art form is as dynamic as it is creative. From the delicate smoothing of acetone baths to the vibrant hues achieved through airbrushing,each technique adds a unique brushstroke to the canvas of innovation. as 3D printing continues to evolve, so too will the possibilities for personalizing and perfecting the objects we bring to life. Whether you’re a seasoned maker or just starting your exploration, remember that the true beauty of 3D printing lies in experimentation and finding. So, keep your imagination well-fueled and your printer buzzing, as the next masterpiece could be just a filament away. Until next time, happy printing!