In a world humming with the exhilarating buzz of technological innovation, 3D printing stands at the forefront, morphing our wildest design dreams into tangible reality. But here’s the kicker—the marvels of this cutting-edge tech don’t have to come at the planet’s expense. Enter the hero of our story: sustainability in 3D printing. Imagine a future where creativity and conservation walk hand-in-hand, where your next 3D-printed treasure is not just a marvel of engineering but also a badge of environmental stewardship. Intrigued? Keep reading to unravel the eco-savvy secrets behind this groundbreaking alliance that’s reshaping our world—one layer at a time. 🌱✨

Greener Materials: Eco-Friendly Choices for 3D Printing

Many eco-conscious makers are turning to greener alternatives in 3D printing to minimize their environmental footprint. Materials like PLA (Polylactic Acid), derived from renewable resources such as corn starch, are popular choices in this domain. PLA is biodegradable, making it a top pick for those wishing to create without contributing to landfill waste. Another exciting development is the use of recycled PETG (Polyethylene Terephthalate Glycol-Modified), which repurposes plastic bottles and other post-consumer waste into high-quality filament. This helps reduce ocean plastic pollution and gives discarded materials a valuable new life.

Another innovative option is composite filaments, which blend biodegradable materials with reclaimed agricultural by-products like wood, coffee grounds, or even algae. These composites not only reduce the reliance on petroleum-based plastics but also add a unique aesthetic and tactile quality to the prints. Furthermore, companies are developing biodegradable PVA (Polyvinyl Alcohol) supports that dissolve in water, further reducing waste. By embracing these greener alternatives, creators can make a significant positive impact, indicating that sustainability and creativity can indeed go hand-in-hand.

| Material | Source | Eco-Benefit |

|---|---|---|

| PLA | Corn Starch | Biodegradable |

| Recycled PETG | Plastic Bottles | Reduces Pollution |

| Wood Composite | Reclaimed Wood | Uses Agricultural Waste |

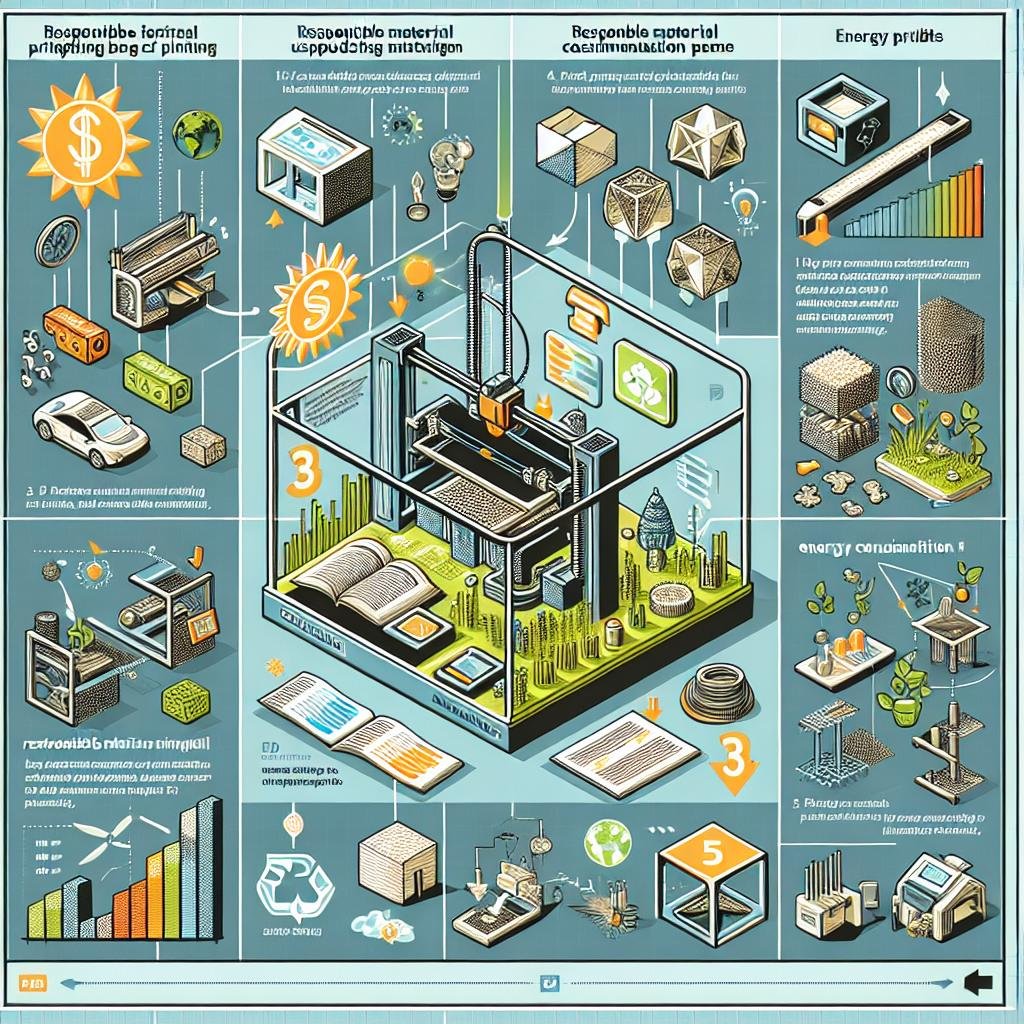

Energy Efficient Printing: Save Power, Save the Planet

Printers play a pivotal role in the world of 3D printing, but they can also be serious electricity guzzlers if not managed correctly. By integrating energy-efficient practices, you can effortlessly trim down your power consumption and reduce your carbon footprint. One effective method is opting for machines with energy-saving modes, which automatically power down during periods of inactivity. Additionally, you can upgrade to smart power strips that cut off power to idle devices. Consider these practices if you want your 3D printing to be as green as possible:

- Use energy-efficient printers.

- Enable automatic power-down settings.

- Switch to smart power strips.

| Practice | Energy Saved | Environmental Impact |

|---|---|---|

| Enable Power Saving Mode | Up to 40% | Reduces CO2 Emissions |

| Use Smart Power Strips | Up to 30% | Prevents Phantom Energy Loss |

Material choice can make a huge difference in sustainability too. Opting for biodegradable or recycled filaments not only curbs the amount of raw plastic used but also ensures that what you do use doesn’t add to landfill waste. PLA (Polylactic Acid), for instance, is derived from renewable resources like corn starch and sugarcane, making it a more earth-friendly option compared to traditional petroleum-based materials. Other sustainable practices include:

- Choosing biodegradable filaments like PLA.

- Recycling old prints and material scraps.

- Exploring alternative, more sustainable materials.

Recyclable Filaments: Closing the Loop with Circular Economy

One significant stride in achieving sustainability within 3D printing lies in the use of recyclable filaments. These materials not only reduce the dependency on virgin plastics but also help in minimizing waste. A growing number of companies are innovating to produce filaments from recycled materials like PET and ABS, which would otherwise contribute to landfill accumulation. The integration of these filaments aligns perfectly with the concept of a circular economy, wherein products are continuously reused, remanufactured, and recycled, creating a closed-loop system. Embracing these materials can drastically reduce the environmental footprint of 3D printing, contributing to a more sustainable future.

| Recyclable Filament Types | Source Material |

|---|---|

| PETG | Recycled Water Bottles |

| PLA | Biodegradable Plastics |

| rABS | Reclaimed Plastic Parts |

Benefits of using recyclable filaments include:

- Reduction in plastic waste: Less plastic ends up in landfills or oceans.

- Lower carbon footprint: Producing filaments from recycled sources consumes less energy.

- Economic efficiency: Costs can be reduced in the long run by minimizing raw material needs.

Here’s how you can contribute:

- Choose filaments made from recycled materials for your printing projects.

- Encourage the return and recycling of used filaments to complete the loop.

Innovative Practices: Tips for Sustainable 3D Printing

Embracing sustainable practices in 3D printing equips you with the tools to minimize your environmental footprint. One significant step is to choose eco-friendly materials such as PLA (polylactic acid), which is derived from renewable resources like corn starch and sugarcane, and is biodegradable under industrial composting conditions. Another option includes recycled filaments, which are produced from post-consumer recycled plastics. By opting for these materials, you not only contribute to waste reduction but also promote a circular economy.

Additionally, optimizing print settings plays a crucial role in sustainability. Consider the following practices:

- Reduce infill density: Lower infill percentages use less material while maintaining structural integrity.

- Adjust layer height: Higher layer heights can shorten print time and reduce material consumption.

- Print multiple objects at once: Batch printing can help decrease the energy used for heating and cooling the print bed.

Explore implementing these innovative practices to fuse creativity with sustainability in your 3D printing endeavors.

| Tip | Benefit |

|---|---|

| Use Eco-Friendly Materials | Reduces environmental impact |

| Minimize Infill Density | Saves material and energy |

Q&A

Q&A: Sustainability in 3D Printing: What You Need to Know

Q: Hey there! I’ve always wondered, what exactly makes 3D printing sustainable?

A: Great question! 3D printing, or additive manufacturing, is considered sustainable for a few reasons. First, it significantly reduces waste. Traditional manufacturing often involves cutting away parts of a material block, leaving heaps of scraps. 3D printing, on the other hand, builds objects layer by layer, using only what’s necessary. Plus, many 3D printers utilize eco-friendly materials like biodegradable PLA (Polylactic Acid), which is derived from renewable resources like corn starch. Neat, right?

Q: Wow, I didn’t know that! Are there any energy efficiency benefits?

A: Absolutely! While the energy consumption of a 3D printer can vary, it generally uses less energy compared to traditional manufacturing processes. Traditional methods often need large, energy-hungry machines for cutting, milling, and molding. In contrast, 3D printers can often produce parts directly from a CAD file with only minor post-processing. Plus, advancements in 3D printing technology are continually optimizing energy usage, making it even more efficient. Cool, isn’t it?

Q: That’s impressive! But what about the materials? Are they really eco-friendly?

A: Many of them are, yes! PLA, as mentioned, is a superstar in the sustainability realm because it’s biodegradable and made from renewable resources. There’s also a growing trend of using recycled plastics. Some innovative companies are even developing printer filaments from recycled ocean plastics and consumer waste, helping tackle the plastic pollution problem. There’s also an exciting future ahead with materials like algae-based polymers and other bio-composites. The material science behind 3D printing is evolving rapidly!

Q: I love that 3D printing is contributing to cleaner oceans! But what about the carbon footprint?

A: Good point! The overall carbon footprint of 3D printing is largely dependent on the source of energy used to power the printers. If a 3D printer is run on renewable energy, its carbon footprint can be impressively low. Additionally, 3D printing can localize production, reducing the need for transportation and therefore lowering emissions. Custom, just-in-time manufacturing also means less inventory waste and less warehousing. It’s a green win-win!

Q: It really sounds like a game-changer. Are there any famous examples of sustainable 3D printing projects?

A: Definitely! There are several innovative projects making headlines. For instance, the company New Story is using 3D printing to build affordable housing in developing countries. They can print a home in just 24 hours using sustainable building materials. Another cool example is Adidas’ Futurecraft 3D-printed sneakers which incorporate recycled ocean plastics. It’s sustainability and style in one package!

Q: That’s fascinating! Is there anything we as individuals can do to support sustainable 3D printing?

A: Absolutely! Firstly, if you have a 3D printer or plan to get one, opt for eco-friendly filaments like PLA or recycled materials. Secondly, support companies and projects that prioritize sustainability in their 3D printing processes. Lastly, stay informed and spread the word! Awareness and collective action can spur even more advancements in sustainable tech. Together, we can print a better future!

Q: Thanks for all the insights! I’m definitely more excited about the potential of 3D printing now.

A: Glad to hear it! The journey toward sustainability in technology is thrilling, and 3D printing is paving the way in wonderful new directions. Keep exploring and stay curious—who knows what we’ll create next!

To Conclude

As we step into the future, the marriage of sustainability and 3D printing holds an electrifying promise—a promise of innovation that not only propels us forward but also honors our planet. By weaving together thoughtful design, eco-friendly materials, and mindful practices, we can craft a narrative where technology and nature not just coexist, but thrive in harmony.

So, whether you’re a curious creator or a seasoned expert, remember: every layer you print is an opportunity to sculpt a greener tomorrow. The road to sustainability in 3D printing is a journey of endless possibilities, and it’s one we’re all invited to embark upon. Let’s keep pushing boundaries, challenging norms, and building a future where every creation tells a story of care and consciousness. Welcome to the forefront of a revolution—one thoughtful layer at a time.

Until next time, keep innovating and keep caring. 🌍✨