Imagine a world where technology mimics the marvels of nature, where ingenuity and compassion join hands to offer a second chance to the voiceless. Picture a playful pup bounding across a meadow, or a majestic eagle soaring through the sky, all thanks to the magic of 3D printing. Welcome to the fascinating frontier of 3D printed prosthetics for animals—a realm where creativity knows no bounds and every wag of a newly equipped tail or flap of a strengthened wing tells a story of innovation and hope.

In this journey, we’ll unravel the meticulous art and science behind creating bespoke prosthetics that breathe life back into creatures great and small. Whether it’s a turtle with a spiffy new shell or a cat with a custom-fitted leg, the seamless blend of technology and empathy is transforming veterinary care as we know it. So, roll up your sleeves and warm up your 3D printer; let’s dive into the enchanting process of giving our furry, feathered, and scaled friends a new lease on life! 🐾✨

Understanding the Unique Needs of Animal Patients

Veterinary patients come in various shapes, sizes, and species, each with their own distinctive anatomy and movement patterns. This diversity means that a prosthetic designed for a dog might not suit a cat, rabbit, or turtle. It’s crucial to understand the **unique biomechanics** and behavior of the animal in need. For example, a dog’s natural gait and weight distribution differ significantly from that of a bird or a pig. Hence, tailored designs and fittings are essential for ensuring the comfort and functionality of the prosthetic. Customization can include features like adjustable straps, adaptable joints, and even materials chosen to match the pet’s activity level and habitat.

- **Dogs:** Require weight-bearing designs and durable, flexible materials.

- **Cats:** Benefit from lightweight prosthetics that allow for agile movements.

- **Birds:** Need specialized attachments to aid in flight or perching.

- **Reptiles:** May need adaptations to accommodate their unique skin textures and shapes.

| Animal Type | Prosthetic Features |

|---|---|

| Dog | Durable, flexible, weight-bearing |

| Cat | Lightweight, agile, easy-movement |

| Bird | Flight aid, perch support |

| Reptile | Skin-friendly, customized shape |

Knowing the specific needs of various animal patients helps in developing effective and comfortable prosthetics. For instance, **materials chosen** might include soft polymers that mimic the flexibility of natural limbs, or more rigid components that can withstand outdoor activity. The anatomy of each animal leads to various prosthetic shapes and sizes – a tortoise shell attachment, for instance, would require a completely different design approach compared to a prosthetic leg for a rabbit. Taking these considerations into account ensures that each animal not only receives a functional prosthetic but also enjoys improved mobility and quality of life.

Choosing the Right Materials for Durability and Comfort

When crafting prosthetics for our furry friends, selecting the right materials is essential to ensure both **durability** and **comfort**. Unlike typical human prosthetics, animal prosthetics must endure more rugged activities like running, jumping, and playing. Material choices like **medical-grade silicone** for padding, **carbon fiber** for structural strength, and **nylon** for flexibility are excellent options. These materials not only withstand the wear and tear but also enhance the comfort for the animals, ensuring they adapt easily to their new prosthetics.

Understanding the specific needs of different animals can guide material selection. Below are a few tailored suggestions:

- Dogs and Cats: Durable yet lightweight materials like **carbon composite** and **TPU filament** are ideal.

- Birds: **PLA plastic** offers sufficient strength without adding too much weight.

- Smaller Animals (Rabbits, Guinea Pigs): Soft materials like **flexible resin** or **TPE** ensure comfort and adaptability.

| Material | Attribute | Suitability |

|---|---|---|

| Medical-grade Silicone | Comfort | Paws and Joints |

| Carbon Fiber | Strength | Frames |

| PLA Plastic | Lightweight | Bird Limbs |

Designing Ergonomic and Functional Prosthetic Models

Crafting prosthetics for animals is a delicate balance of comfort, durability, and functionality. It starts with a thorough understanding of the animal’s physiology and specific needs. Factors such as the size, weight, and natural gait of the animal must be taken into consideration. To ensure a snug yet comfortable fit, you can use materials that are both **flexible** and **resilient** against wear and tear. Utilizing 3D scanning technology can help capture precise anatomical data, which in turn can be inputted into your 3D modeling software. This data informs the design process, ensuring that each prosthetic is uniquely tailored to the individual animal. Here’s what you should consider:

- Material selection: Choose lightweight yet strong materials like PLA or carbon fiber composites.

- Joint articulation: Incorporate movable joints to mimic natural limb movement.

- Padding: Add soft padding to areas in contact with the animal’s skin to prevent chafing and sores.

Another crucial aspect is testing and iterative improvement. After an initial prototype is created, allow the animal to try it on in a controlled environment. Observe its behavior and make note of any adjustments needed. A flexible approach will ensure the final product offers the best possible mobility and comfort. Employ a feedback loop involving veterinarians and even the pet owners. Regularly consulting with these stakeholders can yield useful insights and lead to significant improvements.

| Aspect | Importance |

|---|---|

| Material Strength | High |

| Weight | Medium |

| Bio-compatibility | Critical |

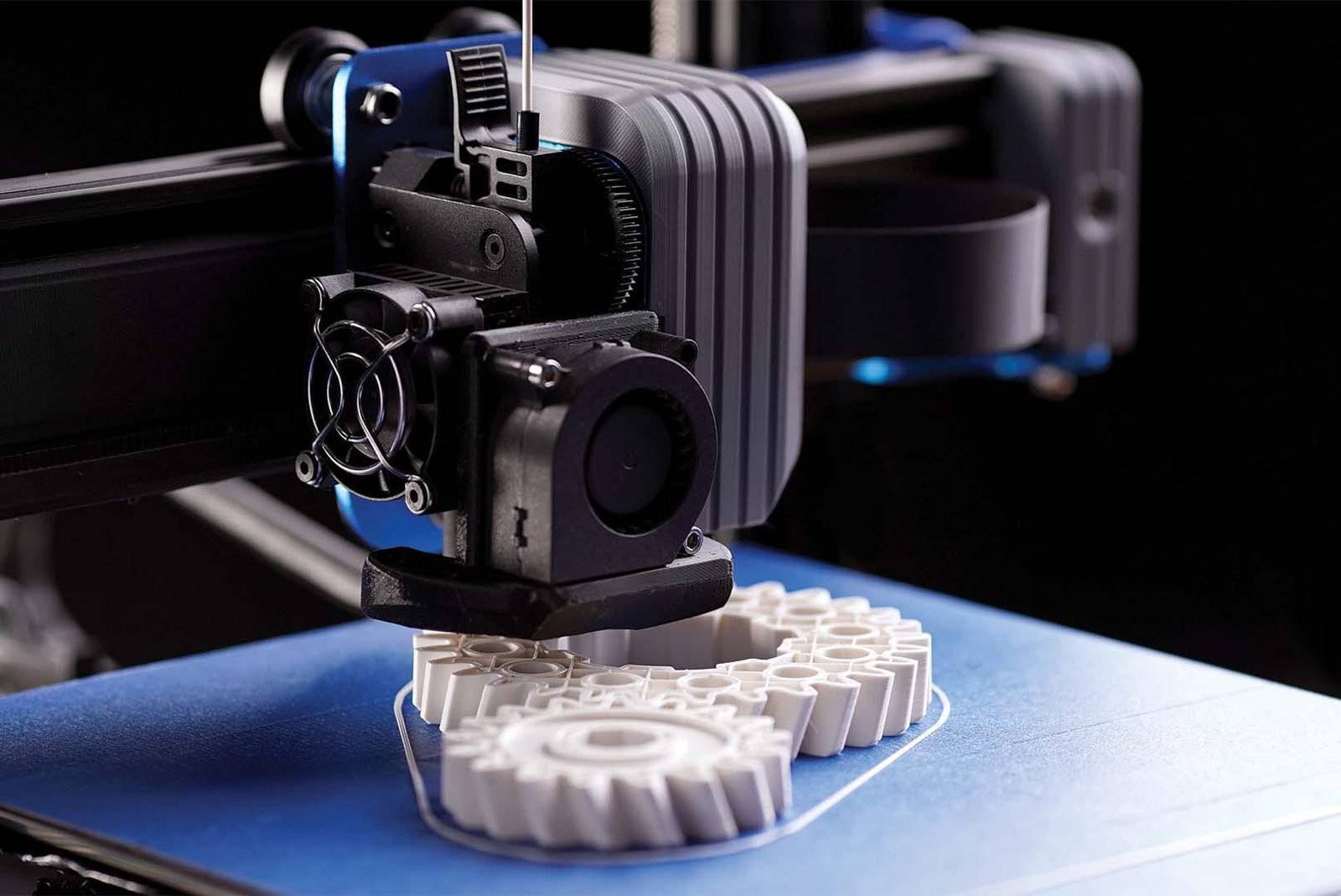

Mastering 3D Printing Techniques for Precise Fabrication

To achieve precision in fabricating 3D printed prosthetics for animals, it’s critical to master several key techniques. Start by choosing the right *filament*; **PLA** and **PETG** are popular choices due to their strength and flexibility, making them ideal for intricate designs required by prosthetics. Utilize a high-resolution printer setting, typically a **layer height of 0.1 mm** or less, to ensure a smooth finish and accurate details. Additionally, **support structures** are essential in complex designs to maintain shape during printing—just ensure they’re easy to remove to minimize finishing work.

Another crucial aspect involves **fine-tuning your slicer settings**. Tweaking parameters like **infill density** and **print speed** can profoundly impact the durability and comfort of the prosthetics. **Post-processing techniques** such as sanding, smoothing with acetone vapors (for ABS), and painting can significantly enhance both functionality and aesthetic appeal. Don’t forget to employ **measurement tools** like calipers for precise fitting and use **scaled models** to test the design before the final print. This careful attention to detail results in prosthetics that not only fit perfectly but also improve an animal’s mobility and quality of life.

| Technique | Benefit |

|---|---|

| High-Resolution Printing | Smooth finish and accurate details |

| Support Structures | Maintain shape during printing |

| Post-Processing | Enhanced durability and aesthetics |

Q&A

Q&A: Crafting 3D Printed Prosthetics for Our Furry (and Feathered) Friends

Q: Why create 3D printed prosthetics for animals?

A: Think about it—every pet and wild animal deserves a chance to move, frolic, and live their life to the fullest! 3D printed prosthetics offer affordable, customizable, and quick solutions for our animal companions who need a helping hand—or paw.

Q: What kinds of animals can benefit from 3D printed prosthetics?

A: From dogs, cats, and rabbits to birds and even turtles, nearly any animal in need of a boost can benefit. If they can wiggle, waddle, or scamper, there’s a 3D printed solution waiting for them!

Q: How do you get started with creating 3D printed prosthetics?

A: First, hop on your computer and learn the basics of 3D printing and design software like Tinkercad or Fusion 360. It’ll be worth it, promise! Next, you’ll need precise measurements (your vet can help), and from there, you can start designing.

Q: What are the materials commonly used for these prosthetics?

A: PLA, PETG, and TPU are the stars of the show! They are safe, sturdy, and durable, making them perfect for creating animal prosthetics that can handle all the jumping, running, and splashing around.

Q: Are there any special considerations for designing these prosthetics?

A: Absolutely! Comfort is key. Make sure edges are smooth and shapes are ergonomic. It’s also crucial to ensure that the prosthetic is durable enough for rambunctious play, but lightweight so it doesn’t tire out our little friends.

Q: What role does a veterinarian play in this process?

A: Veterinarians are your go-to experts for recognizing what kind of support the animal needs. They’ll help with measurements, health considerations, and testing the fit of the prosthetic. Think of them as the quarterbacks of this incredible team!

Q: Can I find designs online or do I have to create them from scratch?

A: You’re in luck! There are repositories like Thingiverse that house amazing designs you can tweak according to your furry friend’s needs. However, if you’ve got a knack for creativity, don’t shy away from crafting something unique.

Q: What challenges might I face while 3D printing prosthetics?

A: Precision is vital, and printing the perfect fit might take a few tries. Animals can be wiggly and unpredictable, so patience and perseverance are your best buddies here. Testing and refining are part of the journey.

Q: Do you need any special tools or equipment besides a 3D printer?

A: Besides your trusty 3D printer, a digital caliper for precise measurements and a heat gun for small adjustments post-printing can be super handy. And don’t forget your toolbox of good vibes for staying positive through the trial and error!

Q: How can you ensure the prosthetic fits well and is comfortable?

A: This is a collaborative effort—work closely with your vet. They’ll help you conduct trials and make adjustments until you see that wagging tail, hopping bunny, or soaring bird. Observe how the animal moves with it, and tweak as necessary for that perfect fit.

Q: Any final words of inspiration for those diving into 3D printing prosthetics for animals?

A: Remember, you’re not just creating a gadget; you’re gifting an animal a second chance at life. It’s incredibly rewarding to see them thrive and enjoy their world, thanks to your ingenuity and kindness. So, dive in, experiment, and let your compassion shine through every print!

The world of 3D printing prosthetics for animals is a blend of technology, creativity, and heart. Whether you’re helping a spirited pup chase its tail again or giving a turtle a new set of wheels, your efforts can make a world of difference. Happy printing, animal champions! 🐾✨

In Summary

As the symphony of whirring 3D printers draws to a close and the once fragmented pieces of filament coalesce into life-changing prosthetics, let’s turn our minds to the profound impact we’re having on our furry, scaly, or feathered friends. We’ve journeyed from the sparks of an idea to the tangible realization of hope and mobility, transforming potential into performance for those creatures who depend on us.

In this boundless realm of 3D printing, each creation embodies more than just technology; it represents resilience, compassion, and our undying commitment to bettering the lives of animals around us. As you venture forth, armed with newfound knowledge and a heart brimming with empathy, remember that every layer of filament brings an animal one step closer to a boundless world of exploration and joy.

So, keep dreaming, designing, and printing. The animals await their heroes—heroes just like you. Happy creating! 🐾✨