In the realm of imagination, where tales of epic battles and intricate fantasy landscapes come to life, the heroes are not just the ones wielding swords but also those who craft each detailed feature and curve with precision. Welcome, fellow dreamers and creators, to the fascinating world of 3D printing high-quality miniatures and models! Whether you’re a seasoned hobbyist or a wide-eyed novice, this journey is designed to unlock the secrets of turning virtual blueprints into tangible art. With a sprinkle of creativity, a dash of technical know-how, and a dollop of patience, we’ll guide you in mastering the alchemy of 3D printing. Ready to bring your miniature masterpieces to life? Let’s embark on this enchanting adventure!

Mastering Your Design: From Concept to 3D Model

Embarking on the journey from an idea to a tangible 3D model requires a blend of creativity, precision, and patience. The initial stage involves brainstorming and sketching out the core design elements, keeping in mind balance, symmetry, and functionality. Here are a few tips to kickstart your design process:

- Conceptualize: Jot down your ideas and create rough sketches. Visualize the final output from various angles.

- Research: Study existing designs for inspiration. Look into the intricacies and challenges faced by others in similar projects.

- Refinement: Refine your sketches, paying attention to detail and ensuring each component fits seamlessly.

After solidifying your concept, it’s time to transition into the digital realm with 3D modeling software. Tools like Blender, Tinkercad, or Fusion 360 are invaluable in this step. To navigate this phase smoothly, here’s a concise guide:

| Step | Action | Tip |

|---|---|---|

| Setup | Create a new project and set your unit measurements. | Ensure units are consistent to avoid scaling issues. |

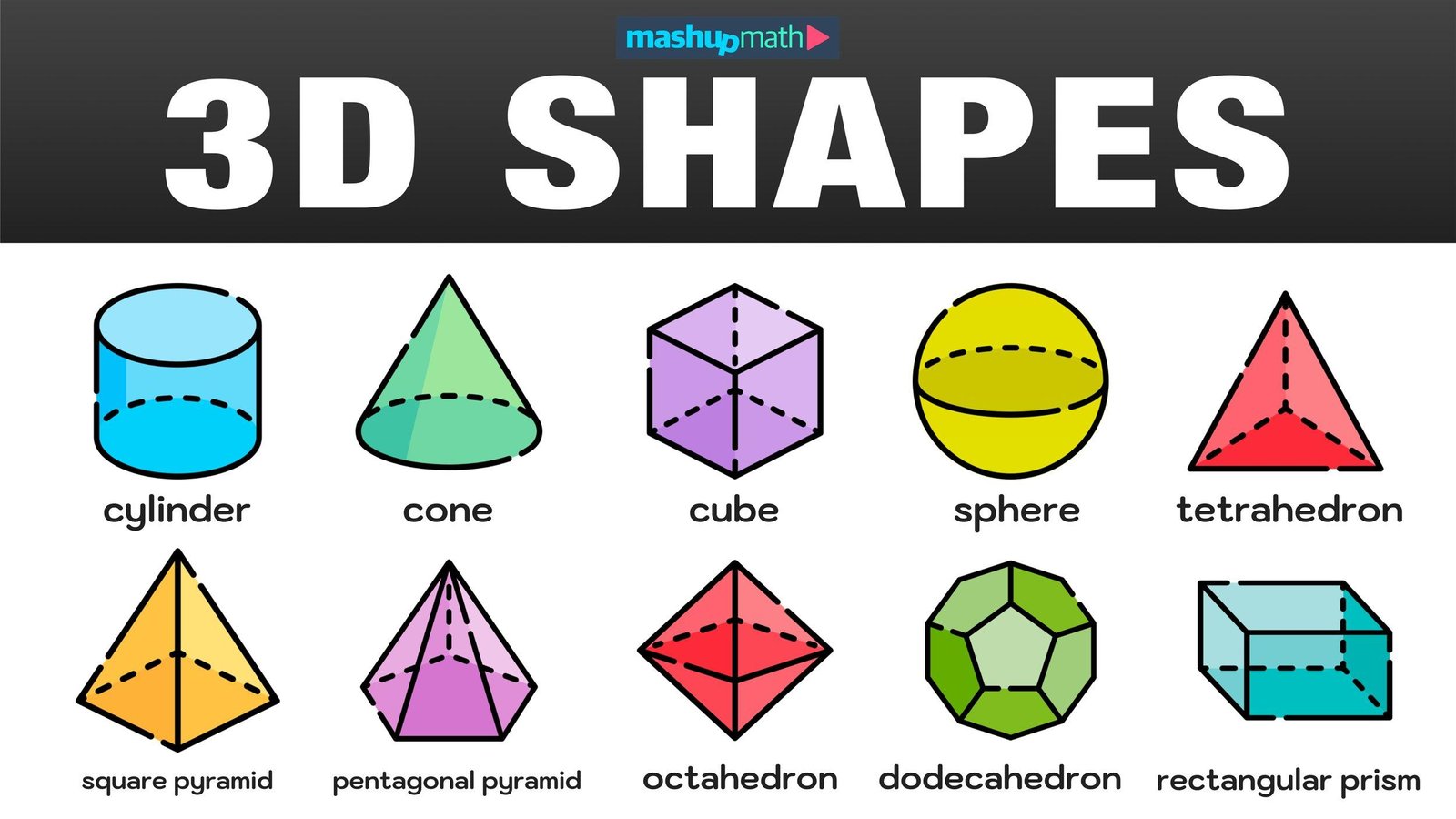

| Basic Shapes | Start with basic geometric shapes to outline the model’s structure. | Use symmetry tools for maintaining balance. |

| Detailing | Add fine details like textures and features. | Zoom in for precision work, ensuring clarity in your models. |

With these steps, you’re on your way to transforming your creative concepts into intricate 3D models ready for printing.

Choosing the Perfect Filament and Printer Settings

An often-overlooked aspect of achieving high-quality miniatures is selecting the right filament and adjusting your printer settings meticulously. The filament you choose can have a significant impact on the final detail and finish of your models. Opt for **PLA** if you’re a beginner; it’s easy to work with and affordable. For more durability and a smoother finish, consider **ABS** or **PETG**; these filaments, however, require more precise temperature control. If you’re aiming for stunning detail, **resin-based** printing may be a worthy upgrade. Here’s a quick comparison to help you decide:

| Filament Type | Pros | Cons |

|---|---|---|

| PLA | Easy to print, affordable | Less durable, can be brittle |

| ABS | Durable, good details | Requires higher temperature, fumes |

| PETG | Smooth finish, durable | Tricky to fine-tune |

| Resin | Highly detailed, smooth surfaces | Expensive, requires post-processing |

After choosing your filament, fine-tuning your printer settings is the key to unlocking superior print quality. Here are some critical settings to dial in:

- Nozzle Temperature: Ensure your nozzle temperature matches the recommended range of your filament type.

- Bed Temperature: A heated bed helps with adhesion and reduces warping; adjust according to filament specifications.

- Layer Height: For finer details, use a smaller layer height; typically 0.1-0.2mm works well for miniatures.

- Print Speed: Slow it down for intricate models; around 30-50mm/s yields better results.

By carefully selecting your materials and meticulously refining your settings, you are well on your way to creating jaw-dropping miniatures and models.

Prepping the Print Bed: Ensuring Optimal Adhesion

A well-prepped print bed is the foundation of successful 3D printing, especially when producing intricate miniatures and models. Start by ensuring your print bed is impeccably clean, as dust and residue can sabotage adhesion. **Isopropyl alcohol** or soap and water work wonders for removing contaminants. If you’re using painter’s tape, make sure it lies flat without bubbling, and replace it as needed. For those utilizing a **glass bed**, a thin layer of glue stick or a dedicated adhesive spray can dramatically improve sticking power.

Next, focus on the temperature settings. Each material has its own optimal bed temperature range, which is crucial for achieving the best results:

- PLA: 50-60°C

- ABS: 90-110°C

- PETG: 70-85°C

A properly leveled bed is equally critical. A basic sheet of paper or an auto-leveling system can help you achieve the perfect distance between the nozzle and the bed. Here’s a quick cheat sheet:

| Material | Bed Temperature | Adhesive Method |

|---|---|---|

| PLA | 50-60°C | Tape or glue stick |

| ABS | 90-110°C | ABS slurry |

| PETG | 70-85°C | Adhesive spray |

By fine-tuning these steps, you’ll ensure your miniatures stick to the bed like magic, ready to emerge with remarkable detail and precision.

Post-Processing: Adding the Finishing Touches to Your Miniatures

Once your miniature emerges from the printer, it’s time to refine and enhance its details. A thorough post-processing routine can transform your print from good to spectacular. Start by removing any **support structures** carefully using hobby clippers. Sanding comes next – use various grit sandpapers, beginning with coarse for rougher areas and progressing to fine grit for smoother finishes. For those hard-to-reach spots, a hobby knife or a needle file can work wonders. **Painting** adds character and depth, so don’t shy away from experimenting with colors, washes, and dry brushing techniques to make every feature stand out.

Finishing touches go beyond just aesthetics; they ensure the durability and longevity of your models. Apply a **primer** before painting as it helps the paint stick better and reveals imperfections that can be further smoothed out. After painting, seal your work with a **clear coat** to protect it from scratches and dust. Here are some essential materials you might need:

- Hobby Clipper

- Various Grit Sandpapers (e.g., 100, 400, 800)

- Needle Files

- Primer

- Acrylic Paints

- Clear Coat

Here’s a quick reference table for the steps and their purposes:

| Step | Purpose |

|---|---|

| Removal of Supports | Ensure clean edges |

| Sanding | Smooth out rough areas |

| Priming | Better paint adhesion |

| Painting | Add color and details |

| Clear Coating | Protect the paint job |

Q&A

How to 3D Print High-Quality Miniatures and Models

Q: What are the essential tools I need to get started with 3D printing miniatures?

A: Fantastic question! To embark on your 3D printing adventure, you’ll need a reliable 3D printer (FDM or resin depending on your preference), high-quality filament or resin, a digital caliper for precise measurements, a scraper for removing prints, an assortment of cleaning tools, and a slicing software program. And don’t forget: plenty of patience and a sprinkle of creativity!

Q: How do I choose the right printer for high-detail miniatures?

A: Ah, the quest for the perfect printer! For high-detail miniatures, a resin (SLA) printer is typically the go-to choice due to its exquisite precision and smooth finish. Think of it as the wizard’s wand in the world of 3D printing! FDM printers are great too, especially for larger models or if you’re working within a budget, but resin printers shine when it comes to capturing those intricate details.

Q: What’s the difference between FDM and resin printers?

A: Excellent inquiry! FDM (Fused Deposition Modeling) printers use a spool of filament, melting and layering it to create your model—best for sturdier, larger prints. Resin printers, on the other hand, use vats of liquid photopolymer resin, which is cured layer by layer using UV light, allowing for a fantastically crisp finish. It’s like watching magic happen before your eyes!

Q: Which materials are best for printing miniatures?

A: For miniature marvels, the material world is your oyster! PLA filament is popular for FDM printers because it’s easy to use and eco-friendly. ABS is another durable option. However, if you’re using a resin printer, you’ll likely be enchanted by standard resin for its detail or specialty resins for different finishes and strength. Some resins capture incredible levels of detail and are ideal for painting post-print.

Q: Do I need to know how to design my own models?

A: Not at all! While designing your own models can be incredibly rewarding and opens a realm of possibilities, you don’t have to become a 3D modeling maestro right away. There are numerous repositories online, like Thingiverse and MyMiniFactory, where you can find a treasure trove of pre-designed miniatures. Dive in and print to your heart’s content!

Q: How can I achieve the best print quality for my models?

A: To attain miniature perfection, here’s the secret recipe: first, ensure your printer is well-calibrated. Level that bed (it’s more important than you might think!), set your layer height low (0.05 to 0.1 mm for resin, 0.1 to 0.2 mm for FDM), and adjust the print speed according to the model’s complexity. Don’t forget proper support structures for those overhanging parts—they’re the unsung heroes of a successful print!

Q: Is post-processing necessary, and what does it involve?

A: Post-processing is where good prints become great! For resin prints, you’ll need to wash the model in isopropyl alcohol to remove any uncured resin, then cure it under UV light. FDM prints can benefit from careful sanding, filling gaps with putty, and priming before painting. It’s a bit like grooming—necessary if you want your miniatures to look their absolute best!

Q: Any painting tips for final touches?

A: Absolutely! When painting miniatures, start with a good primer to give your paints something to grip onto. Use thin coats of paint to avoid obscuring details, and build up the color gradually. Invest in fine brush tips for those intricate parts, and don’t be afraid to blend colors or add washes for depth and realism. Remember, practice makes perfect, and every stroke brings your mini to life!

Q: How do I prevent common printing issues like warping or layer shifts?

A: Ah, the bane of every 3D printing enthusiast’s life! Warping can often be tamed by ensuring your print bed is adequately heated and using adhesives like blue tape or glue sticks to keep your model anchored. For layer shifts, check that all belts are tightened and the printer is on a robust, vibration-free surface. Regular maintenance of your machine is the key—think of it as pampering your loyal pet!

Q: Can you recommend any online communities or resources for newbies?

A: Of course! The 3D printing community is wonderfully supportive and filled with knowledge. Forums like Reddit’s r/3Dprinting and Facebook groups dedicated to your specific printer type are fantastic places to start. Websites like Ultimaker’s Community Hub, the 3D Printing subreddit, and YouTube channels like Maker’s Muse and Uncle Jessy are brimming with tips, tutorials, and inspiration. Dive in and don’t hesitate to ask questions—everyone was a beginner once!

Q: Lastly, what’s the best piece of advice for someone new to 3D printing miniatures?

A: Embrace the journey with curiosity and patience! 3D printing is as much about the process as the results. Every failed print is a learning opportunity, and every successful one is a joy. Experiment, explore different materials and settings, and don’t be afraid to make mistakes. Your next masterpiece is just a print away. Happy printing!

Future Outlook

And there you have it, fellow creators and dream-weavers—a comprehensive guide to turning your 3D printing aspirations into miniature masterpieces. Whether you’re gearing up for an epic tabletop war, crafting intricate collectibles, or simply aiming to push the boundaries of your creative craft, remember that every print teaches us something new.

So, gather your digital blueprints, fine-tune those settings, and let the whirring symphony of your 3D printer be the soundtrack to your artistic journey. Embrace the quirks, celebrate the successes, and share your triumphs with the ever-growing community of makers. Your perfect miniature isn’t just around the corner—it’s at the tip of your filament.

Thank you for joining us on this creative expedition. Until next time, happy printing and may your imagination never cease to build new worlds, one layer at a time.