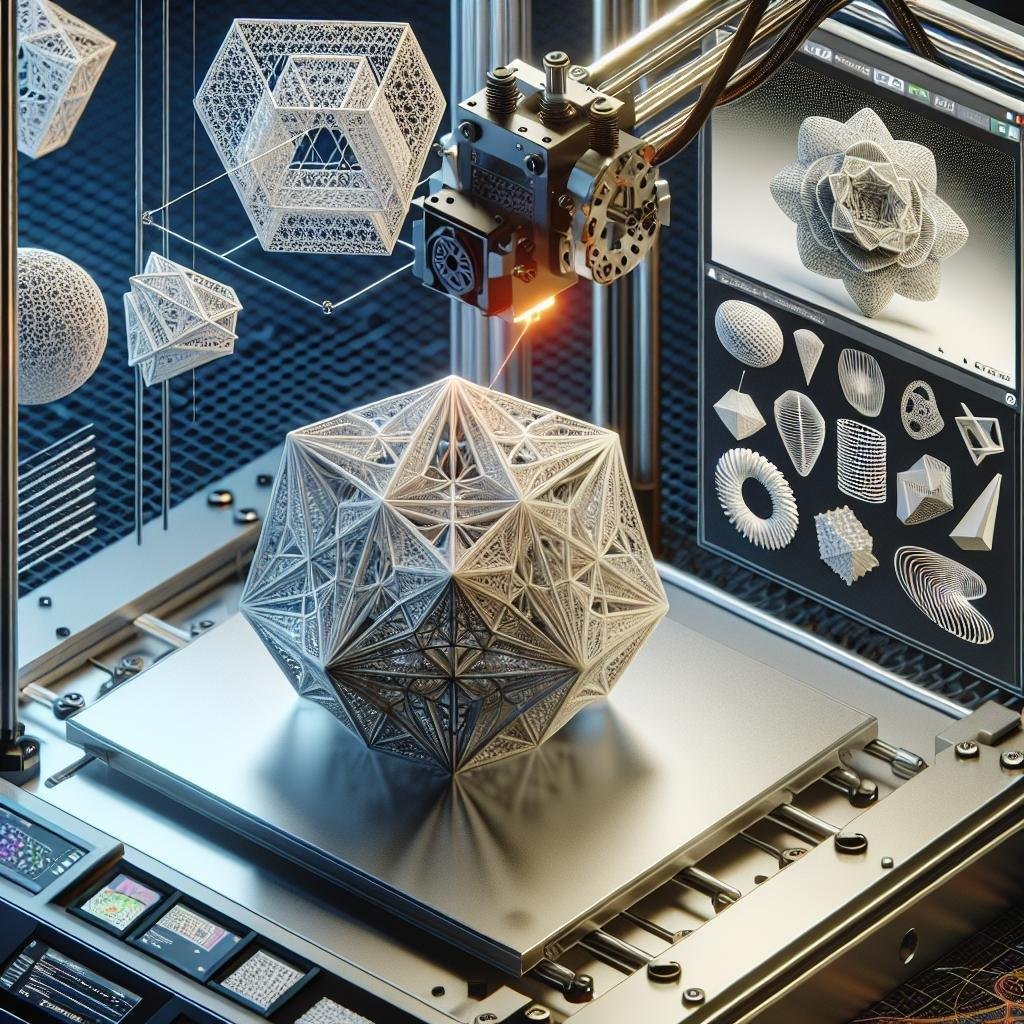

In teh ever-evolving tapestry of technology, the marvels of 3D printing continue to weave new patterns of possibility. Imagine holding a complex geometric shape, one that once lived only in the abstract realms of your imagination, now tangible and precise. Welcome to the enchanting dance of 3D printing, where creativity meets precision to defy the ordinary. Whether you’re a digital artist aiming to breathe life into intricate designs or an engineer seeking to push the boundaries of innovation, mastering the art of 3D printing complex shapes is your gateway to a world where ideas take form with remarkable accuracy. join us on this friendly expedition as we delve into the secrets of transforming intricate digital dreams into precise, physical realities.

Mastering the Art of Slicing for Intricate Designs

Elevate your 3D printing projects by refining how you divide your digital model into layers. The intricacies of slicing are not just about creating layers; they’re about ensuring each layer captures the essence of your design’s complexity.To enhance precision, consider the subtleties of settings like layer height and shell thickness. For instance, a smaller layer height can significantly improve the detailing of curved surfaces and fine features. Concepts such as infill density also play a pivotal role; opting for a higher density can bolster structural integrity without compromising delicacy. Don’t hesitate to experiment with these settings to find the sweet spot that marries robustness with detail.

Moreover, enrich your prints by customizing support structures, ensuring they provide adequate support without marring your design. Gone are the days of manual removal woes, as many slicing software now offer settings to optimize support placement and material. Consider experimenting with support interfaces and density. Here’s a snippet of parameters to adjust, potentially transforming your printing journey:

- Nozzle Temperature: A slight increase can improve layer adhesion but may introduce stringing.

- Print Speed: Slower speeds can enhance quality but increase print time.

- Wall Line Count: more lines can enhance strength but consume more material.

| Parameter | Impact |

|---|---|

| Layer Height | Details & Surface Quality |

| Infill Density | Strength & Weight |

| Support Pattern | Ease of Removal & Print Integrity |

Choosing the Right Materials to Enhance Precision

When venturing into the realm of 3D printing complex geometric shapes,selecting the right materials plays a crucial role in the success of your project. not every filament will yield the same level of detail or structural integrity needed for intricate designs. PLA, as an example, is a popular choice due to its ease of use and ability to handle fine details. However, if you require enhanced durability or temperature resistance, ABS or PETG might be more suited. For those seeking versatility without compromising precision, TPU is a top contender. Choose your material carefully based on parameters like layer adhesion, impact resistance, and elongation at break.

Here are key material attributes to consider:

- Layer Adhesion: Ensures the strength of your print layers when forming intricate shapes.

- Temperature resistance: Necessary for parts exposed to heat.

- Flexibility: Crucial for components that require some level of bend without breaking.

- Surface Finish: affects both aesthetic appeal and part function.

To help in decision-making,here’s a quick comparison:

| Material | Best For | Downside |

|---|---|---|

| PLA | Simple,detailed designs | Low Heat Resistance |

| ABS | Durable structures | emits fumes when printing |

| PETG | Impact-resistant parts | Hygroscopic (absorbs moisture from the air) |

| TPU | Flexible designs | Challenging to print |

Calibrating Your 3D Printer for Flawless Geometry

Achieving precise and flawless prints begins with the art of calibration, a nuanced dance between mechanics and digital magic. Begin by fine-tuning your 3D printer’s extruder temperature and bed leveling. The ideal temperature ensures that your filament melts just right, flowing smoothly to capture intricate details without warping. A level print bed acts as the foundation for your creation, offering stability and accuracy. Sometiems,the devil is in the details,so don’t overlook the importance of adjusting your stepper motor settings. Ensuring each step translates to actual movement is key to an impeccable geometric print.

Consider fine-tuning the PIDs (Proportional, Integral, Derivative) for controlled temperature management, ensuring steady heat without fluctuations. When crafting complex shapes,the power lies as much in your setup as in your settings.Harness the power of your slicer’s optimization features, such as:

- Layer Height: Fine layers capture intricate details.

- Print speed: lower speeds for better accuracy on intricate designs.

- Infill Density: Essential for strength and weight balance.

| Parameter | Optimal Value |

|---|---|

| Extruder Temp | 190-220°C (Depends on filament) |

| Bed Temp | 60-70°C |

| Print Speed | 30-50 mm/s for detailed prints |

These strategies exist not just to troubleshoot errors but to unlock your printer’s potential, allowing you to print with precision and confidence no matter how intricate your design. Embrace calibration as a creative endeavor, an integral part of the overall vision and execution of your project.

Tips and Tricks for Avoiding Common Pitfalls in 3D printing

- Choose the Right Material: Selecting the appropriate filament is crucial when aiming for precision in complex shapes. Consider using high-quality PLA or ABS filaments for excellent dimensional accuracy. Advanced users might explore materials like PETG or Nylon, which offer unique properties such as higher flexibility or strength, enhancing the overall print result.

- Optimize Print Settings: To achieve intricate details, adjusting your slicer settings can make all the difference. Focus on lowering the layer height for finer resolution. Additionally, reducing print speed can minimize mechanical vibrations that often lead to inaccuracies. Don’t forget to tweak the infill percentage: higher infill for sturdy structure and lower for faster prints without compromising on detail.

| Common Pitfall | Solution |

|---|---|

| Warping | Utilize a heated bed and proper adhesion materials such as glue stick or painter’s tape. |

| Layer Shifting | Ensure the printer is on a stable surface and check the belt tension for any looseness. |

| Under-Extrusion | Clean the nozzle regularly and inspect the filament for any blockages or inconsistencies. |

Stay Mindful of Post-Processing Techniques: While precise 3D printing settings lay the foundation, post-processing can perfect your intricate designs. Techniques such as sanding, vapor smoothing, or chemical treatments can enhance surface quality. Additionally,painting or coating can further refine details,making your complex geometric masterpieces truly stand out. Always make sure to test each method on sample prints to master the technique without jeopardizing the final model.

Q&A

Q&A: Mastering the Art of 3D Printing Complex Geometric Shapes with Precision

Q1: What’s the frist step in 3D printing intricate geometric shapes with pinpoint accuracy?

A1: The adventure begins with a sturdy foundation in design. Make sure your 3D design software is up to scratch,allowing for meticulous detailing. Programs like Blender or Fusion 360 are fantastic for crafting those intricate shapes. Time spent here pays off enormously, as a solid design is your blueprint to precision.

Q2: Which materials are best to use when aiming for precision in your 3D prints?

A2: Opt for materials known for their dimensional stability, like PLA or PETG. These materials have low warping potential,which is key when you’re aiming for precision. If you’re feeling adventurous and environmentally conscious,delve into newer materials such as bio-based polymers. They’re both precise and lasting!

Q3: How do print settings impact the precision of complex shapes?

A3: Print settings are your magic wand in achieving precision. Focus on layer height, speed, and temperature settings. A smaller layer height, typically around 0.1 mm, enhances detail but extends print time. Slower speeds often yield higher precision, and dialing in the correct temperature prevents issues like stringing or blobs. Remember, patience is a precision printer’s best friend!

Q4: What role does the printer itself play in this creative process?

A4: The printer is your trusty sidekick! It’s crucial to ensure that your machine is well-calibrated. Regular maintenance, like leveling the print bed and ensuring nozzle cleanliness, is key. Also, consider a printer with a solid frame and precise motor controls. This makes sure that your printer translates your digital design into a tangible masterpiece flawlessly.

Q5: Are there specific techniques to enhance precision for these kinds of prints?

A5: Absolutely! One beloved technique is to use supports strategically to maintain structural integrity during printing. Also, post-processing methods like gentle sanding or heat treating can fine-tune your pieces. Lastly, asseverate precision with brim or raft options in your slicer settings to enhance bed adhesion for your first few layers.

Q6: What common challenges might someone face when printing these shapes, and how can they overcome them?

A6: Warping and layer misalignment are common foes.Conquer these by ensuring your build plate is prepped correctly and using an enclosure to maintain a stable thermal habitat. Additionally, consider iterative testing; print sections of your design to ensure each part aligns perfectly before committing to the full print. Practice makes perfect!

Q7: Any final tips for a newbie venturing into the world of complex 3D printing?

A7: Dive in with an experimental mindset. Trial and error is part of the learning curve, and each misstep is a stepping stone to mastery. engage with the vibrant 3D printing community online; forums and groups are filled with enthusiasts eager to share tips and troubleshoot alongside you. Most importantly, enjoy the process of creation—each print is a unique piece of art!

Whether you’re a seasoned enthusiast or a curious newbie, we hope this Q&A guides you on your exciting journey into 3D printing complex geometric shapes with precision. Happy printing!

The Way Forward

As we draw the curtain on our exploration of 3D printing complex geometric shapes with precision, it’s clear that this innovative realm offers endless possibilities, limited only by your imagination and curiosity. Whether you’re crafting intricate patterns inspired by nature, or designing avant-garde sculptures that defy conventional form, 3D printing empowers you to bring your most enterprising visions to life with unparalleled accuracy.

Remember, every masterpiece begins with a single layer, so embrace the learning curve with patience and enthusiasm. Each click of the software, each whirr of the printer, and every unexpected challenge is a step towards mastery. Soon, you’ll not only create objects that inspire awe but also nurture a passion for precision that transforms your creative process.

Thank you for joining us on this journey. We hope you’re now equipped with the knowledge, techniques, and confidence to venture forth into the mesmerizing world of 3D printing. So go ahead, forge your path, defy gravity, and let your creativity take shape in ways you never imagined possible! Until next time, happy printing and may your designs be as boundless as the universe itself!