Imagine stepping into a world where your footwear is as unique as your fingerprint—a world where shoes are not just an accessory, but a precisely tailored extension of yourself. This isn’t a scene from a futuristic sci-fi movie; it’s happening right now, thanks to the revolutionary magic of 3D printing. In this article, we’ll journey through the fascinating intersection of technology and fashion, exploring how 3D printing is revolutionizing custom footwear design, making bespoke shoes accessible to all. So, lace up and get ready to discover how your next pair of shoes might just be a perfect fit crafted by the precision of a 3D printer.

From Concept to Foot: The Evolution of Custom Shoemaking

Long gone are the days when custom shoemaking relied solely on artisanal craftsmanship and a vast array of hand tools. **3D printing has emerged as a game-changer**, bridging the gap between traditional methods and modern technology. By leveraging precision scanning and customizable design software, 3D printed shoes can achieve an unparalleled level of fit and comfort. Imagine stepping into a store, getting your feet scanned in a matter of seconds, and walking out with shoes optimized exactly for your unique form. Whether it’s for alleviating foot pain, enhancing athletic performance, or simply reveling in a bespoke fashion statement, 3D printing has brought a level of personalization that was previously impossible.

Moreover, this cutting-edge technology isn’t just limited to providing a better fit; it offers sustainability benefits as well. Here are some key advantages:

- Reduction in Waste: Traditional shoemaking often leads to significant material waste, but 3D printing uses only what’s necessary.

- Eco-Friendly Materials: Many 3D printed shoes utilize biodegradable or recyclable materials, helping to reduce the carbon footprint.

- Localized Production: Shoes can be printed on-demand locally, diminishing the need for large-scale shipping and reducing associated emissions.

Take a look at how traditional vs. 3D printed shoemaking stacks up:

| Aspect | Traditional | 3D Printed |

|---|---|---|

| Production Time | Weeks | Days |

| Material Waste | High | Minimal |

| Customization | Limited | Extensive |

Unleashing Creativity: Designing Personalized Footwear with 3D Printing

Imagine a world where you can step into shoes that are uniquely yours, not just in appearance but also in fit and comfort. This is the magic that 3D printing brings to the footwear industry. Traditional shoe manufacturing often relies on standardized sizes, leaving many people with shoes that are too tight, too loose, or simply uncomfortable. With 3D printing, the constraints of mass production are cast aside, allowing for the creation of truly bespoke footwear. Designers can now experiment with intricate patterns, complex structures, and innovative materials that were previously impossible to manufacture. The result? Shoes that are not only functional but also a canvas for artistic expression.

Customization is at the heart of this footwear revolution, and it goes far beyond just selecting colors or adding initials. Customers can now be involved in the design process from start to finish. **Foot scans** ensure a perfect fit, and **material choices**—ranging from flexible plastics to durable rubbers—can be tailored to specific needs. Consider the following options:

- Material Flexibility: Choose from a variety of materials for different parts of the shoe, such as soft, breathable fabrics for the upper and rigid, supportive composites for the sole.

- Style Elements: Integrate personalized designs, including unique patterns, logos, and even textured surfaces that enhance both aesthetics and functionality.

- Sustainability: Employ eco-friendly materials and on-demand production to reduce waste and carbon footprint.

| Option | Benefit |

|---|---|

| Material Flexibility | Enhanced comfort and performance |

| Style Elements | Unique personalization |

| Sustainability | Eco-friendly production |

Step-by-Step: A Look into the 3D Printing Process for Custom Shoes

Imagine a world where your sneakers are literally a perfect fit for your feet, like a glove hugging your toes. This stage of the process begins with a **precision scan of the wearer’s feet**. High-tech scanners create a digital map of every contour and arch, capturing a data set that is as unique as a fingerprint. From this detailed blueprint, designers can craft a 3D model that reflects the exact dimensions and specific needs of the wearer. It’s like having a digital cobbler tailoring your shoes before your eyes!

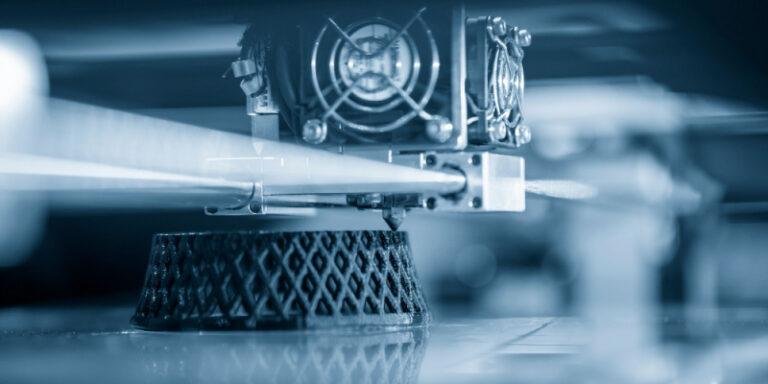

Once your digital twin is perfected, the magic truly begins. The creation process unfolds layer by layer using **additive manufacturing**. This means materials like flexible plastics or resilient rubbers are meticulously applied, building the shoe piece by piece. Here are the main benefits of this approach:

- Customization: Shoes can be tailored for unique foot shapes, specific activities, or personal style preferences.

- Sustainability: Reduces waste by using only the required materials.

- Speed: Significantly faster than traditional shoemaking methods.

| Benefit | Description |

|---|---|

| Fit | Perfectly matched to individual foot dimensions |

| Design | Endless possibilities for customization and creativity |

| Durability | Constructed to last longer under specific conditions |

Take a Perfect Fit: Tailoring Comfort and Style with Innovative Technology

Imagine slipping your feet into shoes that feel like they were crafted specifically for you down to the tiniest contour. Thanks to the magic of 3D printing technology, this is no longer a distant dream but a burgeoning reality. Forget one-size-fits-all; today’s cutting-edge printers utilize **detailed foot scans** to create custom footwear tailored precisely for individual needs. This personalized approach not only enhances comfort but also allows for **highly innovative and unique designs** that mass production simply cannot achieve. And we’re not just talking better fit and comfort—environmental stewardship is another perk as 3D printing significantly reduces waste by utilizing only the exact amount of material needed.

Moreover, this technology opens up numerous possibilities for **customization and personal expression**. Shoe companies can now offer more varied and intricate designs without the hefty price tag and long waiting times associated with traditional methods. **Futuristic Materials**, like bio-degradable plastics and smart textiles, can be effortlessly integrated into new designs. Plus, if you think tweaking colors and patterns is exciting, just wait until you see how 3D printing can integrate other personalized elements like **embedded sensors** for enhanced athletic performance or **therapeutic insoles** for medical conditions. This process isn’t limited to adults either; children’s footwear can be updated as they grow, ensuring consistent comfort and support during crucial developmental stages.

- High precision and fit

- Eco-friendly

- Limitless design options

| Feature | Benefit |

|---|---|

| Personalized Fit | Ultimate Comfort |

| Innovative Materials | Enhanced Durability |

| Eco-Friendly Process | Less Material Waste |

Q&A

Q&A: How 3D Printing is Revolutionizing Custom Footwear Design

Q1: What’s all the buzz about 3D printing in footwear design?

A1: Oh, where to start? Imagine walking into a store and leaving with a pair of shoes that are literally made for you. 3D printing in footwear design is basically taking the concept of custom shoes and kicking it up several notches. It’s like having a personal shoe designer who knows your feet better than you do!

Q2: Okay, but how does it really work?

A2: Great question! It all starts with a detailed scan of your feet. Once they have a digital model, designers can tweak and modify the design to fit your unique foot shape and personal style preferences. Then they feed that data into a 3D printer, and voilà! A pair of shoes that fit you like a glove—except, you know, for your feet!

Q3: Sounds fancy! But is it only for high-end, expensive shoes?

A3: Not at all! While 3D printed shoes did start off in the high-end market, they’re rapidly becoming more accessible. Advances in technology are making the process faster and more affordable, so it won’t be too long before you see these custom wonders in more mainstream stores. Think of it as couture meeting everyday wear.

Q4: Are there other perks to 3D printed footwear besides the perfect fit?

A4: Absolutely! One of the coolest things is the level of customization you can get. Want shoes that look like they belong in a sci-fi movie? No problem! Plus, 3D printing allows for innovative designs that would be impossible or extremely complicated to create with traditional methods. Another huge perk is sustainability. The process is much less wasteful because you’re only using the material that’s needed to make your shoes.

Q5: Can these 3D printed shoes withstand daily wear and tear?

A5: You bet they can! Early versions had their hiccups, but today’s 3D printed footwear is designed to be durable and comfy. Advanced materials and printing techniques have made it possible to produce shoes that can take you through all your daily adventures—whether you’re hitting the gym or just running errands.

Q6: How about style? Do they look like regular shoes?

A6: Oh, they’re anything but regular! Because 3D printing allows for so much creative freedom, designers can experiment with shapes, textures, and colors like never before. You can get everything from ultra-modern, futuristic styles to more classic, elegant designs. Basically, if you can dream it, they can print it.

Q7: This sounds like the future! Do you think 3D printing will eventually take over all shoe manufacturing?

A7: While we’re not pulling out the crystal ball just yet, it’s safe to say 3D printing is a game-changer in the footwear industry. It offers unparalleled personalization, efficiency, and creative possibilities. Traditional manufacturing won’t disappear overnight, but 3D printed shoes are certainly carving out a significant niche and may very well be a big part of the future of footwear.

Q8: How can I get my hands—err, feet—on a pair of these custom beauties?

A8: Although they’re still not quite as common as off-the-shelf sneakers, more and more companies are offering custom 3D printed footwear. Check out brands like Adidas, Nike, and smaller boutique designers who are jumping on the 3D printing bandwagon. Keep an eye out, and soon enough, you’ll find yourself stepping into the future.

Did you enjoy learning how 3D printing is stepping up the footwear game? Keep your eyes peeled for more exciting innovations in the world of custom design! 🌟👟

Concluding Remarks

As we lace up the final thoughts on the transformative power of 3D printing in custom footwear design, it’s clear that we are stepping into an exciting new era. Where once our shoes were mere accessories, they are now becoming bespoke expressions of individual style and need. This leap from traditional cobbling to a high-tech marvel showcases the incredible fusion of art and technology, crafting a path where comfort and innovation converge with elegance.

So, the next time you slip on a pair of perfectly tailored sneakers or marvel at the intricate patterns on custom-designed loafers, remember that you are not just experiencing a product; you’re wearing a testament to human ingenuity. In this brave new world of 3D-printed footwear, every step is a stride toward a future where fashion is not just worn, but also innovatively woven.

Here’s to walking into tomorrow, one cutting-edge step at a time. 🌟👟