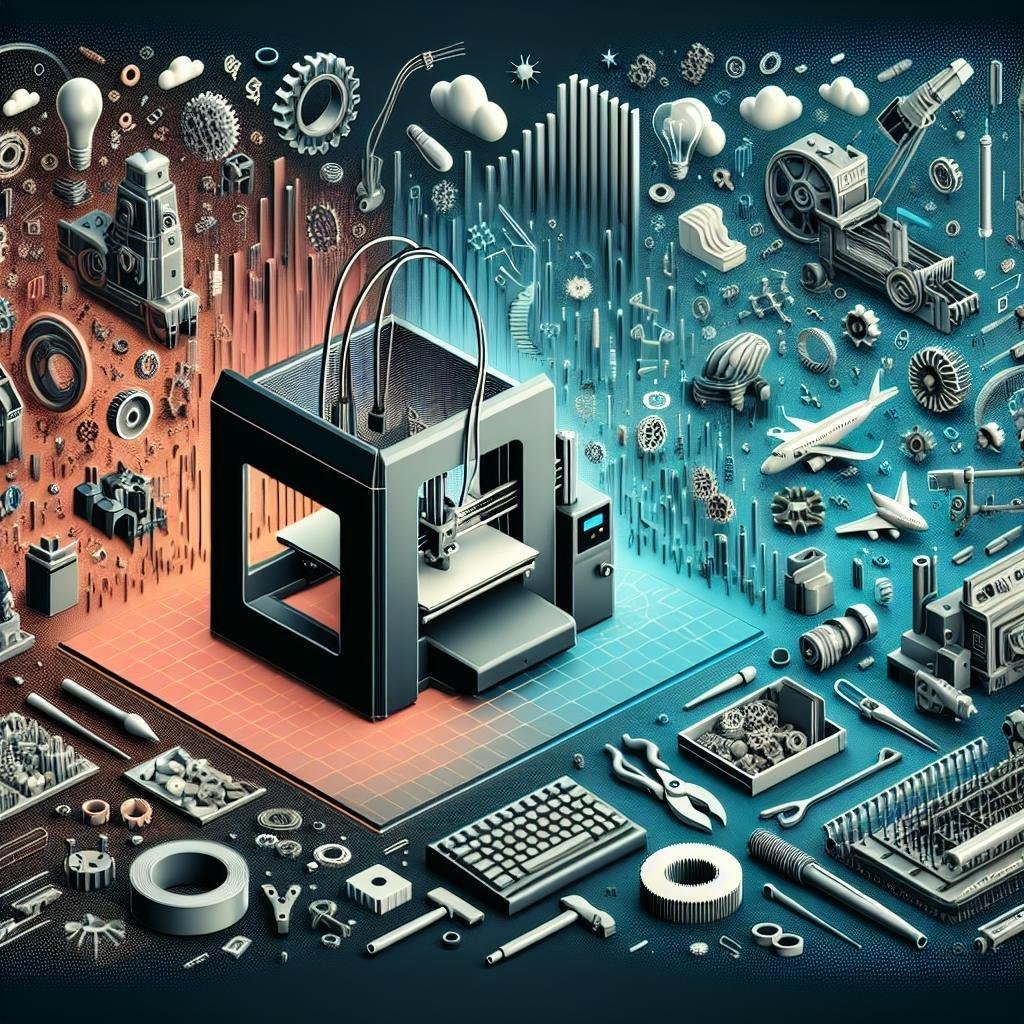

In the bustling world of manufacturing, where the hum of machines and the clatter of assembly lines have long been the soundtrack of production, a silent revolution is taking shape—layer by layer. Imagine a world where creativity takes flight in three dimensions, where design dreams leap effortlessly from screen to reality. welcome to the age of 3D printing, a technological marvel that is reimagining the very essence of how things are made. With its roots firmly planted in the realms of science fiction,3D printing is now reshaping industries,bringing a touch of magic to the mundane. Join us on a journey through innovation and imagination as we explore how this groundbreaking technology is not just bending the rules but rewriting them entirely, transforming customary manufacturing into a playground of endless possibilities.

Shaping Tomorrow: The Impact of 3D Printing on Age-Old Manufacturing

In the dynamic landscape of modern manufacturing, the emergence of 3D printing stands as a beacon of innovation, reshaping paradigms that have withstood centuries. Traditional manufacturing techniques, reliant on subtractive processes and labor-intensive methodologies, are witnessing a profound transformation. 3D printing, or additive manufacturing, introduces versatility and precision that where previously unfathomable. It allows for the creation of intricate designs that are not bound by the constraints of conventional methods. As a result, small entrepreneurs and large corporations alike are harnessing the power of this technology to produce customized products with unparalleled energy efficiency and reduced material waste. Key industries, such as aerospace, healthcare, and automotive, are already integrating 3D printing to manufacture complex components that are lightweight yet highly durable, ushering in an era of bespoke production.

- Customized Production: Tailor products to individual needs.

- Reduced Waste: Use only the material that is needed.

- Speed and Precision: Eliminate the delays of traditional manufacturing processes.

Moreover, 3D printing democratizes manufacturing, offering unprecedented opportunities for innovation across the globe. Entrepreneurs and hobbyists, frequently enough referred to as “makers,” can now transform ideas into physical realities without the need for sizable capital investments. This shift empowers a new generation of creators who are unencumbered by geographical limitations. Consider the following benefits:

| Benefit | Description |

|---|---|

| Accessibility | Easy access to prototyping for anyone with a 3D printer. |

| Cost Efficiency | Notable reduction in production and tooling costs. |

| Creativity | Encourages innovation with fewer constraints on design. |

Revolutionizing Production: Embracing Flexibility and Customization

The advent of 3D printing technology has introduced a remarkable shift towards greater flexibility and customization in the production landscape. Unlike traditional manufacturing,where mass production frequently enough means uniformity,3D printing allows for the creation of intricate,bespoke designs that precisely meet the demands of the end-user. This ability to tailor products on-demand opens doors to more creative solutions and reduces the waste associated with surplus production. With less material usage needed for each prototype, designers have the freedom to innovate rapidly without the constraints of conventional methods. industries from healthcare to aerospace are leveraging this technology to create items that once seemed impossible, such as custom medical implants or lightweight aircraft components.

- Cost-efficient prototypes: Eliminate the cost of molds and tooling.

- Direct-to-consumer: craft personalized products efficiently.

- Eco-amiable operations: Use only necessary materials, minimizing waste.

Moreover, the rise in customization capabilities fueled by 3D printing is redefining consumer expectations. Imagine ordering a pair of shoes online, custom-fitted to your feet, crafted and delivered within days.This is no longer a distant dream but today’s reality. Companies can offer enriched, tailor-made experiences while maintaining a sustainable model. In essence, 3D printing empowers consumers with strong, durable, and cutting-edge products. The combined forces of flexibility and customization are unlocking new possibilities in how products are designed, manufactured, and experienced globally.

| Innovation Areas | Benefits |

|---|---|

| Medical Industry | Custom implants and prosthetics |

| Fashion Design | Personalized fits, unique designs |

| Aerospace | Lightweight, stronger components |

Sustainable Innovations: How 3D Printing is leading Green Manufacturing

In the realm of green manufacturing, 3D printing emerges as a game-changer with its ability to significantly lower waste production, utilizing precise additive processes that minimize excess material. Unlike traditional manufacturing, which frequently enough requires cutting away large portions of material, 3D printing builds items layer by layer, leading to better resource efficiency. This innovation extends the lifespan of materials,as manufacturers can print only what is needed when required,reducing surplus production. Furthermore, 3D printing facilitates the use of recycled materials, encouraging a circular economy. As a notable exmaple, companies are experimenting with bioplastics and recycled polymers, making it a remarkable example of sustainable production innovation.

The environmental benefits of 3D printing aren’t just theory but are being vividly showcased in real-world applications. Here are some field-leading initiatives:

- Energy Efficiency: By producing items close to or at the point of use,energy consumption related to transportation and logistics is drastically reduced.

- Local Production: Supports decentralization and provides manufacturing capabilities to remote locations, empowering smaller businesses and reducing carbon footprints.

- On-Demand Customization: With no need for large inventories, manufacturers can create bespoke items, cutting down unneeded production.

| Factor | Traditional Manufacturing | 3D Printing |

|---|---|---|

| Waste Production | high | Low |

| Customization Flexibility | Limited | High |

| Time to Market | Long | Short |

Charting a New Path: Strategic Recommendations for the Manufacturing Industry

As we stride deeper into the era of innovation,strategic shifts in the manufacturing sector have become imperative. 3D printing emerges as a luminous torchbearer, lighting the way for possibilities never imagined before. This technology introduces a newfound flexibility, allowing manufacturers to pivot quickly from traditional, rigid processes to versatile, customized solutions. Consider the benefit of rapid prototyping, which enables businesses to transition from concept to production in a fraction of the time, thus reducing lead times and cost overruns. With 3D printing,the manufacturing landscape is no longer dominated by economies of scale but rather economies of scope. Imagine producing limited quantities of bespoke goods without a substantial markup — a transformation indeed!

To align with this evolving trend,manufacturers must consider shifting their focus to embrace rapid digitization,fostering a culture of innovation,and exploring novel material compositions. Here are a few strategic recommendations that could help in paving the path to success:

- Adopt digital twinning: Create virtual models for better design iterations and predictive maintenance.

- Invest in workforce skills: Training employees in 3D modeling and additive manufacturing techniques.

- Develop partnerships: Collaborate with tech startups to leverage specialized expertise.

Taking a cue from early adopters, companies embracing this disruption have seen concrete benefits. As shown in the table below, firms integrating 3D printing report marked improvements on key performance indicators.

| KPI | Traditional Approach | 3D Printing Advantage |

|---|---|---|

| Time to Market | 6 months | 2 months |

| Customization Flexibility | Limited | High |

| Production Cost | High | Moderate |

in embracing these strategic shifts, the manufacturing industry not only stands to enhance operational efficiency but also to tap into new markets, driving both growth and sustainability.

Q&A

Q&A: How 3D Printing is Disrupting Traditional manufacturing

Q1: What exactly is 3D printing, and why is everyone buzzing about it?

A1: Great question! Imagine having a magical machine that can create three-dimensional objects right before your eyes, layer by layer. That’s 3D printing for you! It’s generating a buzz because it allows for unbelievable customization, quick prototyping, and sometimes even manufacturing directly, all at a fraction of the traditional cost. It’s like having your cake and printing it too!

Q2: how is 3D printing changing the landscape of traditional manufacturing?

A2: Ah, the heart of the discussion! 3D printing is shaking things up by making production more flexible and localized. Traditional manufacturing ofen involves long lead times,centralized production facilities,and excess waste. With 3D printing,you can produce parts on-demand,reducing the need for large inventory and transportation logistics. Plus, it’s eco-friendlier due to less material waste. Essentially, it’s making manufacturing more nimble and planet-friendly!

Q3: Can 3D printing really compete with age-old manufacturing methods like machining and forging?

A3: While traditional methods aren’t going extinct anytime soon, 3D printing is carving out its niche. It’s ideal for complex designs that are challenging or impossible to achieve with conventional techniques. While 3D printing might not yet replace high-volume production lines,it’s a formidable contender for custom jobs,rapid prototyping,and even small to medium-scale production runs. It’s like having a Swiss Army knife for manufacturing in your hands.

Q4: What industries are most affected by this 3D printing wave?

A4: Honestly, 3D printing is causing ripples across the board, from automotive and aerospace to healthcare and consumer goods.In aerospace,parts are becoming lighter yet stronger,while in healthcare,custom prosthetics,and even organ models for surgical planning are becoming a reality. The possibilities are as expansive as your imagination!

Q5: Are there any challenges holding back 3D printing from fully taking over traditional manufacturing?

A5: Absolutely, like any new kid on the block, 3D printing has its share of growing pains.challenges like material limitations, slower production speeds for certain processes, and high initial setup costs can be hurdles. Moreover,as with any technology,there needs to be an ongoing emphasis on quality assurance and meeting regulatory standards. The good news? The industry is rapidly innovating to overcome these challenges,and the future looks promising!

Q6: How can businesses start integrating 3D printing into their operations?

A6: First,it’s all about understanding where 3D printing can add value to your business. Is it in prototyping, reducing lead times, or offering custom products? Start small, experiment, and gradually scale as you identify prosperous applications. Collaborating with experts and tapping into the growing community of makers can also provide valuable insights. It’s a journey, and every small step can lead to significant leaps!

Q7: Looking to the future, where do you see 3D printing heading?

A7: The sky’s the limit! As materials become more diverse and technology advances, we can expect 3D printing to tackle even more complex and critical tasks. It might even revolutionize remote construction or make space exploration more feasible by manufacturing tools and parts off-planet. The future is 3D, and it’s unfolding right before our eyes.

Feel free to explore and embrace the possibilities of 3D printing—it might just reshape how we think about making things!

Wrapping Up

As we stand on the precipice of a new industrial revolution, it’s clear that 3D printing is more than just a technological marvel; it’s a beacon lighting the path to a future where creativity and possibility reign supreme. From intricate prototypes to life-saving medical devices, this transformative technology is reshaping the very fabric of manufacturing, turning the impossible into the possible, one layer at a time.

As traditional manufacturing joins forces with the limitless potential of 3D printing, we find ourselves in an exciting era of innovation, collaboration, and endless ingenuity. Who knows what remarkable creations lie just beyond the horizon?

So whether you’re an industry veteran watching in awe, an entrepreneur ready to pioneer new frontiers, or simply a curious mind eager to explore, 3D printing holds the promise of an exciting new world. The gears of change are already in motion, and this is just the beginning. So, let’s embrace this journey together, armed with knowledge, enthusiasm, and a spool of filament, as we delve into the wondrous possibilities that 3D printing has yet to unveil.