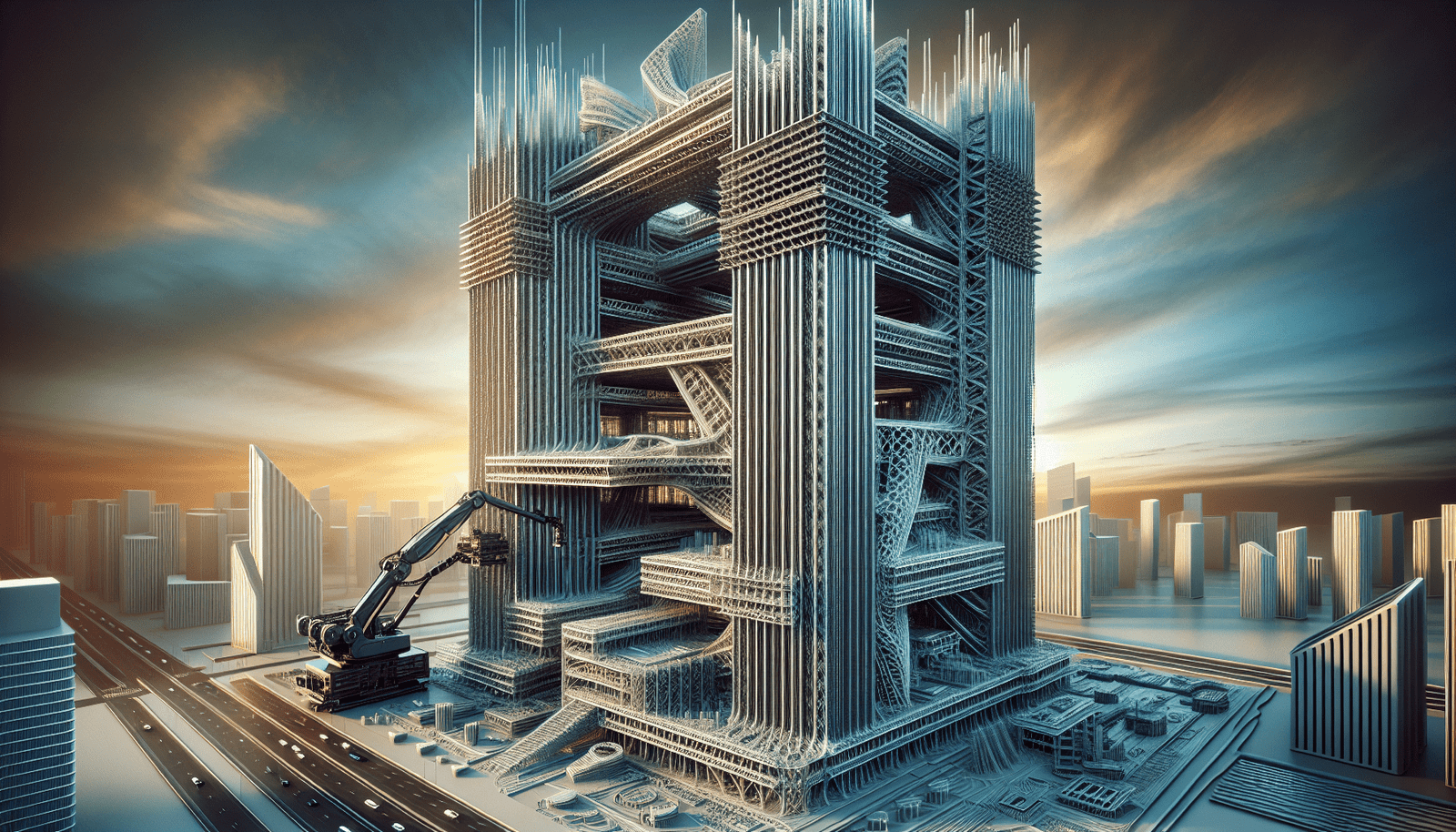

Imagine a world where the construction industry becomes faster, more efficient, and less wasteful. Thanks to advancements in technology, this is now becoming a reality through the use of 3D printing. From creating intricate architectural models to constructing entire houses, 3D printing is revolutionizing the way we build. In this article, we will explore the various ways in which 3D printing is being utilized in the construction industry, and how it is transforming the way we design and construct the spaces we inhabit. Brace yourself for a journey into the future of construction.

1. Introduction to 3D Printing in Construction

Overview of 3D printing technology

3D printing has revolutionized various industries, including construction. This innovative technology involves the creation of three-dimensional objects by adding layers of material. Through a process called additive manufacturing, 3D printers are capable of transforming digital designs into physical objects. In the construction industry, this technology offers numerous benefits including cost savings, time efficiency, design flexibility, and reduced waste.

Importance of 3D printing in the construction industry

The construction industry has traditionally relied on conventional manufacturing and construction methods. However, the introduction of 3D printing has brought about a paradigm shift in the way buildings and infrastructure are constructed. This technology has the potential to significantly improve efficiency, sustainability, and affordability. By embracing 3D printing in construction, the industry can overcome various challenges and meet the growing demand for innovative and sustainable solutions.

2. Advantages of 3D Printing in Construction

Cost savings

One of the primary advantages of 3D printing in construction is the potential for cost savings. Traditional construction methods often involve high labor costs, material wastage, and long project timelines. 3D printing allows for the efficient use of materials, reducing waste and minimizing the need for costly manual labor. Additionally, the ability to automate certain processes can lead to significant time and cost savings.

Time efficiency

Time is of the essence in the construction industry, and 3D printing offers a solution to streamline the building process. With traditional construction methods, it can take months or even years to complete a project. In contrast, 3D printing enables rapid construction by layering materials and creating complex structures in a fraction of the time. This time efficiency not only reduces project timelines but also allows for faster occupancy or utilization of the constructed spaces.

Design flexibility

3D printing provides unparalleled design flexibility in the construction industry. Unlike traditional construction techniques that often have limitations in terms of design complexity and customization, 3D printing offers the freedom to create intricate and unique structures. This technology enables architects and designers to explore innovative designs, shapes, and geometries that were previously unattainable. From curved walls to intricate facades, 3D printing opens up new possibilities for creative and aesthetic expression.

Reduced waste and environmental impact

Sustainability is a growing concern in the construction industry, and 3D printing offers a sustainable solution. With traditional construction methods, a significant amount of materials end up as waste. In contrast, 3D printing minimizes material wastage by only using the necessary amount of materials required for the construction. This reduction in waste not only reduces costs but also has a positive environmental impact by minimizing the extraction and production of raw materials.

3. Types of 3D Printing Technologies

Fused Deposition Modeling (FDM)

Fused Deposition Modeling (FDM) is one of the most commonly used 3D printing technologies in construction. It involves the extrusion of a thermoplastic material through a heated nozzle, which deposits layers of material to create the desired object. FDM is known for its simplicity, low cost, and versatility, making it suitable for a wide range of construction applications.

Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS) is another 3D printing technology used in construction. It utilizes a high-powered laser to selectively fuse powdered materials, such as plastics or metals, to create solid objects. SLS allows for the creation of complex geometries and high-resolution objects. However, it requires specialized equipment and is generally more expensive than FDM.

Stereolithography (SLA)

Stereolithography (SLA) is a resin-based 3D printing technology that uses ultraviolet (UV) light to selectively cure liquid resin into solid objects. SLA offers high precision and accuracy, making it ideal for creating detailed architectural models and prototypes. However, it is generally slower compared to other 3D printing technologies and may require additional post-processing.

Concrete Extrusion

Concrete extrusion is a specific 3D printing technology designed for the construction industry. It involves the extrusion of a cementitious material through a nozzle, which deposits layers to create a solid structure. Concrete extrusion technology has been successfully used to construct buildings, bridges, and other infrastructure projects. This technology offers the advantage of using locally available materials and has the potential to revolutionize the construction industry.

4. Applications of 3D Printing in Construction

Construction of buildings

3D printing has the potential to revolutionize the construction of buildings. By using large-scale 3D printers, it is possible to construct entire buildings in a fraction of the time compared to traditional construction methods. This technology allows for the creation of complex architectural designs, reduces labor costs, and minimizes material wastage.

Prefabrication of components

Prefabrication is a common practice in the construction industry, and 3D printing can enhance this process. By 3D printing precast components, such as walls, columns, and facades, construction projects can be completed more efficiently. Prefabricated components can be easily transported and assembled on-site, reducing the time and labor required for on-site construction.

Architectural design and prototypes

The architectural design process often involves creating physical models and prototypes to visualize and assess design concepts. 3D printing technology allows architects to quickly and accurately create scale models, enabling better communication and collaboration with clients and stakeholders. This technology also facilitates the exploration of innovative design ideas and the testing of structural integrity and functionality.

Infrastructure development

3D printing is not limited to building construction; it also has applications in infrastructure development. Bridges, tunnels, and other infrastructure components can be 3D printed using specialized materials and technologies. This approach offers the potential for cost savings, faster construction, and enhanced durability. 3D printing also enables the customization of infrastructure elements to suit specific requirements and locations.

5. Examples of 3D Printing Projects in Construction

The Office of the Future in Dubai

Located in Dubai, the Office of the Future is the world’s first fully functional 3D-printed office building. The entire structure, including the walls, floor, and ceiling, was 3D printed using a combination of concrete and polymer materials. This project showcased the potential of 3D printing in the construction industry, demonstrating the speed, efficiency, and sustainability benefits of this technology.

The Canal House in the Netherlands

The Canal House in Amsterdam, Netherlands, is another notable 3D printing project in construction. This three-story house was constructed using a large-scale 3D printer that extruded layers of biodegradable plastic. The use of 3D printing technology allowed for the creation of unique and customized features, such as intricate facades and curved walls, while minimizing material waste.

The Apis Cor Project in Russia

The Apis Cor project in Russia gained international attention for its innovative approach to constructing affordable housing using 3D printing. The project utilized a mobile 3D printer that was able to quickly construct a small house on-site. By 3D printing the walls and roof layer by layer, the project demonstrated the potential for cost-effective and sustainable housing solutions.

6. Challenges and Limitations of 3D Printing in Construction

Cost of equipment and materials

One of the main challenges of implementing 3D printing in construction is the cost of equipment and materials. 3D printers capable of constructing large-scale structures can be expensive, making it challenging for smaller construction companies to adopt this technology. Additionally, specialized materials used in 3D printing can be costly, further adding to the overall expense.

Limited scale and size of printed objects

While 3D printing offers design flexibility, there are limitations regarding the scale and size of printed objects. Current 3D printing technologies have constraints in terms of the maximum size and height of structures that can be printed. This limitation can restrict the application of 3D printing to smaller buildings and components, prohibiting its use in large-scale construction projects.

Quality control and regulatory compliance

Maintaining quality control and ensuring regulatory compliance are important considerations in the construction industry. With the introduction of 3D printing, quality control processes need to be adapted to ensure the structural integrity and durability of printed objects. Additionally, existing building codes and regulations may need to be updated to accommodate the use of 3D printing in construction.

Need for skilled workforce

The successful implementation of 3D printing in construction requires a skilled workforce with specialized knowledge in operating and maintaining 3D printing equipment. Training and education programs need to be developed to equip construction professionals with the necessary skills to leverage this technology effectively. The shortage of skilled personnel proficient in 3D printing techniques can be a significant barrier to its widespread adoption in the industry.

7. Future Prospects and Trends

Scaling up the use of 3D printing in construction

As 3D printing technology continues to advance and become more affordable, there is potential for its widespread adoption in the construction industry. Scaling up the use of 3D printing can lead to improved efficiency, reduced costs, and increased sustainability in construction projects. Companies investing in research and development are continuously pushing the boundaries of 3D printing, making it a promising technology for the future of construction.

Integration of robotics and automation

The integration of robotics and automation is another trend that is expected to shape the future of 3D printing in construction. Automated processes can enhance the speed and accuracy of 3D printing, allowing for faster construction and improved quality control. Robotics can also enable the construction of complex structures that would otherwise be challenging or impossible with manual labor.

Sustainable construction practices

Sustainability is a key focus in the construction industry, and 3D printing has the potential to contribute to sustainable construction practices. By utilizing local materials, minimizing waste, and reducing the carbon footprint associated with transportation, 3D printing can help reduce the environmental impact of construction projects. Future developments in 3D printing technologies and materials can further enhance its sustainability attributes.

8. Case Study: ICON’s Vulcan 3D Printer

Overview of ICON’s Vulcan printer

ICON’s Vulcan 3D printer is a cutting-edge construction technology designed to revolutionize affordable housing. This large-scale printer is capable of constructing houses using a proprietary blend of concrete materials. The Vulcan printer operates with precision and speed, allowing for the creation of structurally sound and aesthetically pleasing buildings. ICON’s Vulcan printer has the potential to address the global housing crisis by providing affordable and sustainable housing solutions.

Construction of affordable housing using 3D printing technology

ICON’s Vulcan printer has been successfully used in various projects to construct affordable housing. By leveraging 3D printing, ICON can reduce construction costs, minimize material wastage, and accelerate the construction process. The use of 3D printing technology enables the creation of high-quality housing units that meet regulatory standards and offer improved living conditions. ICON’s Vulcan printer serves as a prime example of how 3D printing can revolutionize the affordability and accessibility of housing.

9. Conclusion

Summary of the impact of 3D printing in construction

The introduction of 3D printing technology has brought about significant advancements in the construction industry. Its advantages, such as cost savings, time efficiency, design flexibility, and reduced waste, have the potential to transform the way buildings and infrastructure are constructed. From the construction of buildings and prefabricated components to architectural design and infrastructure development, 3D printing has a wide range of applications in the construction sector.

Potential future developments

The future of 3D printing in construction looks promising. As technology continues to advance, we can expect to see the scaling up of 3D printing in construction projects, integration with robotics and automation, and the adoption of sustainable construction practices. Case studies like ICON’s Vulcan printer demonstrate the potential of 3D printing to address the global housing crisis and provide affordable and environmentally friendly housing solutions.

By embracing 3D printing in construction, the industry can overcome various challenges, maximize efficiency, and contribute to a more sustainable and innovative built environment. With continuous advancements in technology and the support of skilled professionals, the potential for 3D printing to revolutionize the construction industry is immense.