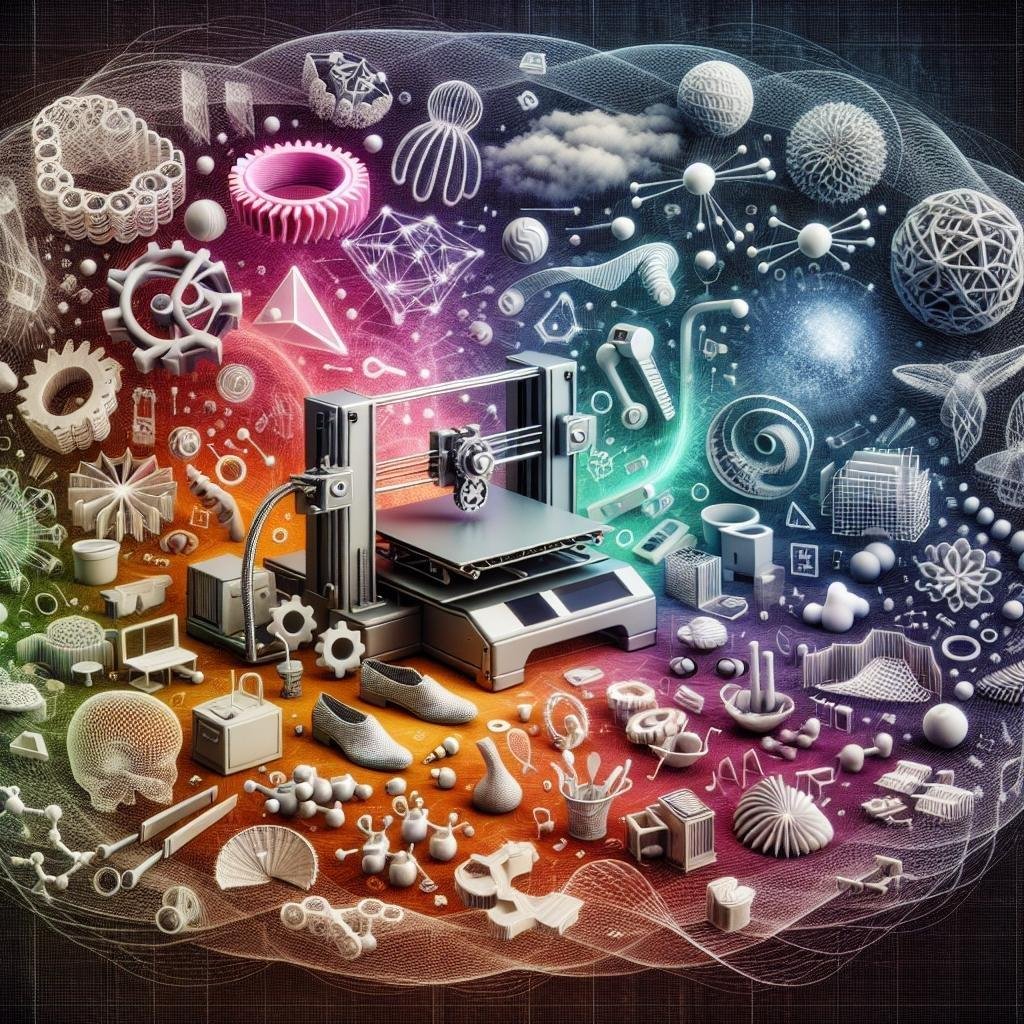

Imagine holding an idea in your mind one moment, and cradling its tangible form in your hands just hours later. Welcome to the world of 3D printing—an alchemist’s dream where imagination swiftly transforms into reality. This magic, however, is not just for fantastical tales or futuristic daydreams. It’s a practical, accessible, and incredibly efficient tool for anyone looking to breathe life into their innovations. If you’re on the cutting edge of design, engineering, or entrepreneurial pursuits, rapid prototyping through 3D printing might just be your next best friend. Buckle up, dear reader, as we dive into why this technology is revolutionizing the way we prototype, iterate, and ultimately, innovate.

Design Freedom Unleashed: Creativity Without Limits

Imagine a creative playground where your ideas aren’t constrained by traditional manufacturing limitations. With 3D printing, the boundaries of design no longer apply, allowing you to experiment with intricate geometries, complex internal structures, and personalized touches that would be impossible or prohibitively expensive using conventional methods. This dynamic tool empowers you to think outside the box and transform abstract concepts into tangible prototypes quickly and efficiently.

From envisioning intricate models to testing functionality with physical iterations, here’s what makes this technology indispensable for innovators:

- Speed: Rapid turnaround times from idea to prototype.

- Cost-Efficiency: Reduced material waste and production costs.

- Customization: Tailored designs that meet specific requirements.

- Flexibility: Seamless adjustments and refinements.

One look at how different industries leverage 3D printing for prototyping reveals an array of applications and benefits:

| Industry | Use Case |

|---|---|

| Automotive | Engine part prototypes |

| Healthcare | Customized prosthetics |

| Fashion | Innovative accessories and footwear |

| Aerospace | Aerodynamic testing models |

Speed Meets Precision: Faster Turnarounds, Finer Details

In the fast-paced world of product development, there’s a constant race against the clock. 3D printing steps up as the ultimate game-changer, offering lightning-speed turnarounds without compromising on intricate details. Traditional manufacturing methods often entail lengthy processes and tooling changes, which can slow down innovation. By contrast, 3D printing allows you to skip the queue. Imagine having a prototype in your hands within hours instead of weeks! This agile approach not only accelerates timelines but frees up your resources to focus on what truly matters—design refinement and usability testing.

- Reduces Lead Time: Prototypes ready in hours.

- Minimizes Waste: Additive process means less material usage.

- Enables Complex Designs: Achieve the intricacy you need.

But speed isn’t the only player in this game; precision is its equally important counterpart. The advanced capabilities of modern 3D printers can capture details as fine as a hair’s breadth, ensuring your designs come to life exactly as envisioned. It’s particularly advantageous for industries where accuracy is paramount, like healthcare, automotive, and aerospace. Need a prototype with moving parts or complex geometries? No sweat—3D printing handles those with ease, providing a perfect blend of speed and precision that facilitates creative solutions to engineering challenges.

| Feature | Benefit |

|---|---|

| Fast Turnarounds | Prototype in a matter of hours |

| High Precision | Detailing up to 20 microns |

| Complex Designs | Effortlessly handles intricate geometries |

| Material Efficiency | Minimizes waste in production |

Cost-Effective Innovation: Budget-Friendly Prototyping

One of the standout reasons to integrate 3D printing into your prototyping workflow is its affordability. Traditional prototyping methods often involve extensive labor, material wastage, and time-consuming processes. In contrast, 3D printing allows you to create detailed and complex prototypes with minimal material use. This not only cuts down on costs but also significantly reduces the time needed from concept to tangible product. Imagine the difference between spending weeks manually shaping a model and producing a perfect example overnight! This cost-efficiency doesn’t just stick to materials either—time savings translate directly into reduced labor costs and faster market entry.

Another noteworthy advantage is the flexibility it offers. 3D printing allows for easy modifications, enabling you to iterate on designs swiftly without heavy financial investments. Traditional methods might require redesigning molds or machining, which quickly adds up. Here’s what you gain from embracing this technology:

- Rapid iteration: Make quick adjustments based on feedback without cumbersome retooling.

- Customization: Easily tailor designs to specific needs or preferences.

- Material variety: Experiment with different materials to find the most effective solution.

With these benefits, it’s clear that 3D printing has revolutionized prototyping, making innovation accessible and budget-friendly.

Eco-Friendly Engineering: Sustainable Solutions with 3D Printing

One of the most compelling reasons to look into 3D printing for rapid prototyping is its inherent eco-friendly benefits. Traditional manufacturing methods often generate significant waste, as materials are cut away or left unused. In contrast, additive manufacturing, the core principle behind 3D printing, uses only the material necessary to build the prototype layer by layer. This process results in a minimalistic production footprint, conserving resources and reducing waste. In addition, many 3D printers support the use of biodegradable materials, such as PLA (Polylactic Acid), which is derived from renewable resources like corn starch and sugarcane, making your prototypes not just efficient but also environmentally responsible.

Beyond the reduction of waste, 3D printing allows for localized production, drastically cutting down the carbon emissions traditionally associated with shipping and logistics. Imagine printing your prototype right at your office or home, eliminating the need for long transportation routes and packaging. Furthermore, this technology accommodates a diverse range of materials, including recycled plastics and composites, which can significantly mitigate the environmental impact compared to virgin materials. Consider these sustainable perks as you brainstorm your next breakthrough, and remember, with 3D printing, the possibilities are virtually endless!

| Traditional Methods | 3D Printing |

|---|---|

| Significant Waste | Minimal Waste |

| High Carbon Footprint | Reduced Carbon Emissions |

| Non-renewable Materials | Biodegradable & Recycled Materials |

Q&A

Q&A: Why You Should Consider 3D Printing for Rapid Prototyping

Q: What is the big deal about 3D printing for prototyping anyway?

A: Ah, where do I even begin? Imagine crafting your ideas into tangible objects quicker than you can say ”eureka”! With 3D printing, your designs leap right from your imagination onto your desk, elegantly transforming digital concepts into real-world prototypes. It’s a creativity revolution!

Q: Sounds intriguing, but is it only for tech-savvy folks?

A: Not at all! While some tech know-how can help, 3D printing is becoming wonderfully user-friendly. Design software ranges from beginner to advanced, and there are countless tutorials out there. Plus, the community around 3D printing is incredibly supportive. Think of it as the ultimate collaborative adventure.

Q: How fast are we talking about here for getting prototypes made?

A: Speed is where 3D printing truly shines. Traditional methods often require weeks or even months for prototyping. With 3D printing, you could have a physical model in just a few hours! This rapid turnaround accelerates the iteration process, helping you refine your designs quickly and efficiently.

Q: And what about costs? Is it going to burn a hole in my pocket?

A: Surprisingly, no! The initial investment in a 3D printer might sound steep, but in the long run, it can be incredibly cost-effective. Think about all the money you’ll save on outsourcing prototypes. Plus, the material costs are generally much lower compared to traditional manufacturing methods.

Q: Can 3D printing handle complex designs?

A: Absolutely! 3D printing excels at creating intricate, complex, and even geometrically impossible designs that traditional manufacturing can’t handle. You can let your imagination run wild, knowing that the technology can keep up with your creativity.

Q: What materials can I use for 3D printing prototypes?

A: Oh, the variety is fantastic! Depending on your needs, you can choose from plastics, resins, metals, and even biocompatible materials. This versatility means you can prototype everything from simple gadgets to advanced medical devices. It’s like having a mini-manufacturing empire at your fingertips!

Q: But what if I mess up my design? Is it the end of the world?

A: Definitely not! One of the beauties of 3D printing is the ease at which you can iterate. If a prototype doesn’t turn out as expected, you can revise your design and print again without significant delay or cost. It’s the perfect playground for trial and error, leading to better innovations.

Q: Is 3D printing eco-friendly?

A: Indeed, it can be! Traditional manufacturing often results in a lot of waste material. In contrast, 3D printing is an additive process, meaning it builds objects layer-by-layer, using only the material that’s needed. This can vastly reduce waste, making your prototyping process greener and more sustainable.

Q: How does 3D printing fit into the big picture of innovation?

A: 3D printing is a game-changer for innovation. It democratizes the manufacturing process, allowing startups and individual inventors to compete with larger companies. The ability to rapidly produce and iterate designs fosters a culture of relentless improvement and creative exploration. It’s like giving wings to your ideas!

Q: Where can I learn more if I’m sold on 3D printing?

A: Dive into the ocean of resources available online! From YouTube tutorials to forums and community meetups, there’s a wealth of information and support. And who knows? You might even become the next 3D printing guru, inspiring others with your innovative prototypes!

Ready to bring your ideas to life at lightning speed? Gear up, dive into the world of 3D printing for rapid prototyping, and watch your creativity soar! 🚀

Closing Remarks

As we wrap up our exploration into the dynamic world of 3D printing for rapid prototyping, it’s clear there’s a colorful, inventive universe awaiting your creative touch. Imagine transforming brilliant ideas from fleeting sparks into tangible realities—no longer bound by traditional constraints. Embrace the flexibility, speed, and cost-efficiency that 3D printing brings to your prototyping process. Whether you’re an entrepreneurial visionary or a hands-on craftsman, this technology is your gateway to innovation.

So, why wait? Step into the future, one layer at a time, and let 3D printing ignite your next groundbreaking project. Your prototypes aren’t just models; they’re the first steps towards something extraordinary. Happy printing!