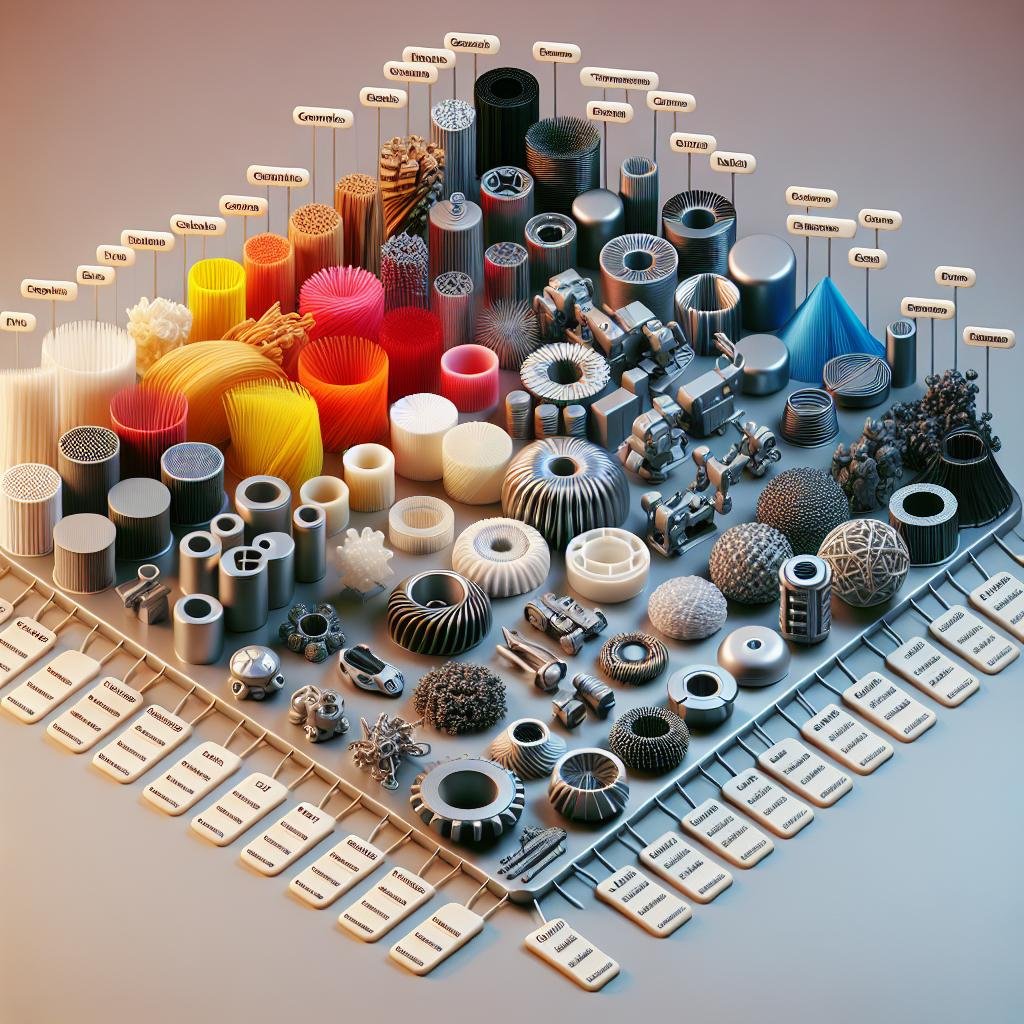

In the ever-evolving realm of innovation, 3D printing emerges as a modern marvel, reshaping the boundaries of creativity and manufacturing. Imagine a world where your dreams take shape layer by meticulous layer, materializing into tangible reality right before your eyes. As more creators and hobbyists embark on this fascinating journey, the spotlight turns to one crucial question: what materials can be wielded to bring these digital blueprints to life? Join us as we embark on an enchanting exploration thru a treasure trove of materials-from the everyday to the unusual-that fuel this technological renaissance. Whether your sculpting a delicate trinket or engineering complex components, the world of 3D printing materials is brimming with possibilities as diverse and vibrant as the projects they manifest. Grab your virtual toolkit and let’s dive into the colorful palette of options that await in the imaginative universe of 3D printing!

Exploring the Rainbow of Filaments: From Plastics to Beyond

Embark on a vibrant journey through the spectrum of 3D printing filaments! In the realm of plastics, you’ll find the likes of PLA (polylactic Acid) and ABS (Acrylonitrile Butadiene Styrene) leading the charge. PLA is beloved for it’s eco-friendliness and ease of use,perfect for beginners or anyone embracing sustainability. Conversely, ABS is the go-to for those seeking durability, making it ideal for functional parts and prototypes. Add a dash of sparkle with PETG (Polyethylene Terephthalate Glycol),which offers the best of both worlds: versatility and strength.Meanwhile, Nylon steps up as the relentless workhorse known for its toughness and resistance.

But 3D printing extends beyond conventional plastics into a world of innovative materials. Enter the conductive filaments, which are opening avenues in electronics projects. There’s wood and metal-filled filaments, bringing authenticity and creative textures to prints that look and feel surprisingly organic. For those delving into more industrial realms, you’ll discover carbon fiber blends that provide lightweight yet incredibly sturdy solutions. The future is gleaming with potential as ceramic and biodegradable filaments revolutionize what we no about the process. Here’s a swift overview:

| Material Type | Characteristics |

|---|---|

| PLA | Eco-friendly, easy to print |

| ABS | Durable, heat-resistant |

| PETG | Flexible, strong |

| Nylon | Tough, withstands stress |

| Wood-filled | Natural texture, aesthetic appeal |

| Carbon Fiber | light, robust, industrial use |

Unveiling the Strength: Metals and Their 3D Printing Potential

In the realm of advanced manufacturing, 3D printing with metals is a fascinating frontier, melding the ancient strength of metals with cutting-edge technology. Delve into a world where stainless steel, titanium, and aluminum are just the beginning. Each metal brings its own unique traits to the 3D printing process,with stainless steel providing durability and corrosion resistance,titanium exemplifying strength while remaining lightweight,and aluminum standing out due to its conductivity and versatility. Let your imagination run wild, blending the architectural robustness of metals with the flexibility of 3D design!

But these aren’t the only players in the game.Discover the robust applications of nickel, copper, and cobalt-chrome alloys, perfect for industries ranging from aerospace to medical. Here’s a quick overview to get you started:

| Metal | Key Characteristics | Applications |

|---|---|---|

| Stainless Steel | Corrosion resistance, strength | Aerospace, automotive |

| Titanium | High strength-to-weight ratio | Medical implants, aerospace |

| Nickel | Heat resistance, toughness | Energy sector, high-temperature applications |

- Aluminum: Known for its lightness and conductivity, aluminum is often used for prototypes and intricate designs.

- Copper: Its excellent electrical conductivity makes it a staple in the electronics industry.

- Cobalt-Chrome Alloys: Perfect for crafting dental and orthopedic implants, thanks to their biocompatibility and strength.

by harnessing the potential of metals in 3D printing, the possibilities truly become limitless, paving the way for innovations that were once merely fantasies.

Sculpting in Silence: The Subtle Art of Printing with Ceramics

When it comes to the tranquil craft of 3D printing with ceramics, enthusiasts revel in the meditative nature this medium demands. Unlike other materials, ceramics require a delicate balance between creativity and precision. the serene process starts with the selection of materials, often including various clay bases mixed with additives to enhance printability. For artisans daring to explore this quiet craft, common options include:

- Clay-based blends

- Porcelain slurries

- Grog-infused mixtures

The dreamy dance of printing with ceramics doesn’t end with mere trial and error; it wholeheartedly embraces scientific exploration. To achieve the best results,it’s crucial to understand the properties of the chosen material. Clays, for example, present the perfect union between fragility and resilience when handled with care. Below, a brief comparison of popular ceramic materials used for 3D printing:

| Material | Main Properties | Use Case |

|---|---|---|

| Clay-based blends | Flexible, smooth finish | Sculptures, pottery |

| Porcelain slurries | High-gloss, fine texture | Delicate art pieces |

| Grog-infused mixtures | Strength, textured surface | Durable art, textured designs |

Rethinking the Future: Eco-Friendly and Sustainable Materials

As we delve deeper into sustainable innovation, the 3D printing arena is being revolutionized by eco-friendly materials that promise to reduce waste and carbon footprints.PLA (Polylactic Acid) stands at the forefront-a biodegradable thermoplastic derived from renewable resources like cornstarch and sugarcane. Known for its environmental benefits, PLA is increasingly popular in creating everything from household items to intricate prototypes. In addition to PLA, recycled PETG is gaining traction. By transforming discarded PET bottles into printable filament,this material mitigates plastic waste,giving recyclables a second life in a most creative fashion.

Another promising avenue lies in the use of innovative biocomposites, blending plastics with organic fibers to craft robust, eco-resilient materials. Some unique blends include coconut shell powder and hemp fibers, which enhance both the strength and aesthetic appeal of the printed products. Algae-derived polymers are also breaking new ground, capitalizing on the rapid growth rate and availability of algae to offer a renewable, biodegradable choice. These materials are not only sustainable; they also encourage a transformative outlook on resource utilization in manufacturing. Embracing these options is a step towards a responsible, greener future.

| Material | Source | Eco Benefit |

|---|---|---|

| PLA | Cornstarch,Sugarcane | Biodegradable,Renewable Resources |

| Recycled PETG | Plastic Bottles | Reduces Waste |

| Biocomposites | Coconut,Hemp | Enhances Strength,Aesthetic Appeal |

| Algae Polymers | Algae | Rapidly Renewable |

Q&A

Q: what is 3D printing,and why is it so popular nowadays?

A: 3D printing,frequently enough called additive manufacturing,is a magical process that turns digital designs into tangible objects by layering materials,bit by bit. Imagine a baker creating a multi-layered cake, but rather of icing, it uses materials like plastic or metal! Its popularity has soared as it democratizes creativity, allowing anyone from artists to engineers to create complex structures with the push of a button. Plus, it reduces waste and is super customizable-what’s not to love?

Q: What types of materials can be used for 3D printing?

A: Oh, where to begin! The palette of materials available for 3D printing is as diverse as a rainbow. We’ve got the user-friendly plastics like PLA and ABS, perfect for hobbyists and everyday DIYers. For the more industrial tinkerers out there, there’s nylon and polycarbonate. Then we have resins, which are great for high-detail models. Going bigger? We have metals like stainless steel and titanium, perfect for aerospace and automotive industries. And let’s not forget ceramics, which can make your creations as sturdy as those ancient Greek statues.

Q: Are there any eco-friendly materials that can be used in 3D printing?

A: Absolutely! Sustainability is the name of the game these days,isn’t it? Eco-friendly materials are making great strides in the 3D printing world. PLA, derived from corn starch, is biodegradable and a popular green choice. There are also recycled PET filaments made from recycled bottles-what a way to give plastic a second life, right? Plus, researchers are venturing into experimental materials like algae-based filaments. The future is green and it’s achievable, one layer at a time!

Q: Can food be used in 3D printing? Asking for a hungry friend!

A: Your friend has a great idea! Yes, food and 3D printing do mix.Chocolate, dough, and even cheese are being used to make edible masterpieces with precision that would impress any pastry chef. Imagine printing your own desserts, tailored perfectly to your taste and whimsy. Culinary 3D printing is still in its early days, but who knows? Maybe one day it’ll take over your kitchen and make perfectly layered sandwiches a reality!

Q: Is it safe to use all these materials in a typical home surroundings?

A: Safety first, always! most materials like PLA and some resins are indeed safe for home use. Though, when handling more advanced materials like metals or specific resins, you’d want to ensure proper ventilation and perhaps even a dedicated workspace. Safety goggles and gloves aren’t just fashion accessories-they’re essential when printing with any materials that emit fumes or require high temperatures. So,gear up responsibly,and let the creative,safe,and fun adventure of 3D printing commence!

Remember,every material choice brings a whole new world of possibilities to your 3D creations,so mix,match,and experiment to your heart’s content!

The way Forward

As we wrap up our exploration of the innovative world of 3D printing materials,it’s clear that the possibilities are as diverse as they are exciting. From the sturdy resilience of metals to the versatile adaptability of plastics, and even the eco-friendly charm of bio-materials, the palette for 3D printing is ever-expanding. These materials not only define the future of manufacturing but also ignite the creative spark within each of us, beckoning us to imagine new horizons where art, technology, and sustainability meet. So, whether you’re a seasoned 3D printing enthusiast or someone just starting to dip your toes into this fascinating realm, remember that the only limit is your imagination. Happy printing, and may your creations be as bold and brilliant as the materials you choose!