In a world where technology often races ahead faster than we can keep up,there exists a interesting intersection between innovation and healing—3D printing. Imagine walking into a room filled wiht the gentle hum of machines, their intricate dance culminating in creations that once belonged solely to the realm of science fiction. This is no ordinary workshop; it’s a hub where human ingenuity meets the precision of robotics to redefine the future of medicine. Today, we delve into the remarkable role of 3D printing in crafting custom medical implants, a revolution quietly transforming lives with personalized care. From a mother gaining mobility with a tailor-fit hip joint to a child receiving a custom-designed prosthetic limb colored in their favorite superhero shades, the wonder of 3D printing is reshaping the very essence of healing, one layer at a time. Journey with us as we explore this world of possibilities, where every print is not just an object but a story—a story of hope, renewal, and extraordinary care.

Revolutionizing Personal Care with Precision Crafting

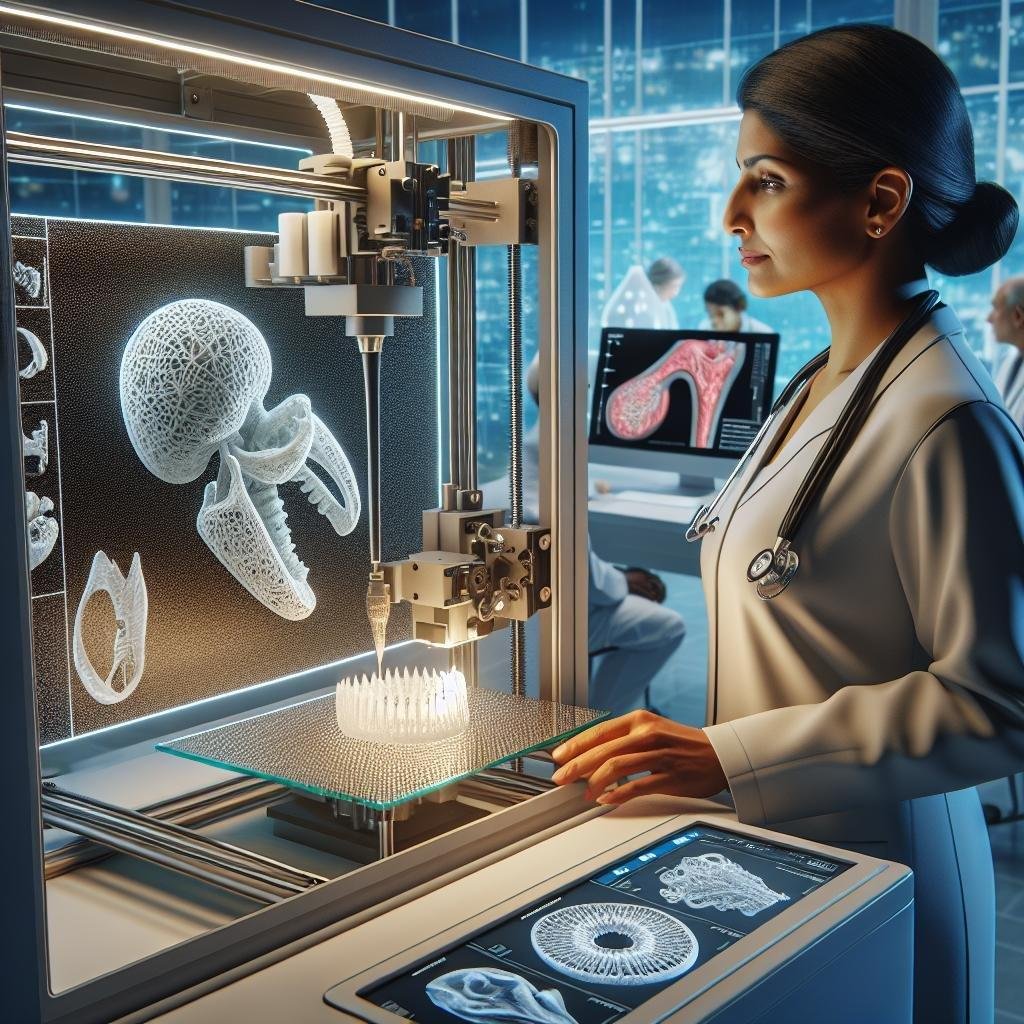

3D printing has truly transformed the landscape of medical implants by leveraging the power of customizability and precision. Customary manufacturing often left patients with one-size-fits-all solutions that may not cater perfectly to unique body anatomies. With 3D printing, though, it’s possible to create bespoke implants tailored specifically to an individual’s requirements. This means better compatibility, reduced risk of complications, and a more natural fit which translates to faster recovery times and improved comfort. Imagine a world where complex implants such as spinal cages, cranial plates, or joint replacements can be sculpted precisely to the contours of the patient’s body, creating a new era of personalized healthcare.

- custom Fit: Each implant can be individually crafted to fit perfectly within the patient’s unique anatomy.

- Innovative Materials: The use of biocompatible materials ensures that implants are not only safe but also durable.

- Reduced Costs: By eliminating the need for traditional molds, manufacturing costs can be considerably reduced.

Furthermore, the potential applications extend beyond just the implant itself.3D printing allows for the creation of surgical guides and models, enabling surgeons to plan and practice complex procedures with unprecedented accuracy. In this way,3D printing becomes an invaluable tool not only for the personalization of medical implants but also for refining surgical interventions. Here’s a rapid look at how 3D printing compares with traditional techniques:

| Aspect | Traditional Techniques | 3D Printing |

|---|---|---|

| customization | Limited | High |

| Production Time | Long | Short |

| Cost | High | Variable |

Harnessing Innovation: A Deep Dive into 3D printing Technologies

In the fascinating realm of modern medicine, 3D printing is at the forefront of innovation, transforming how custom medical implants are designed and manufactured. This technology allows for the creation of implants that are meticulously tailored to the unique anatomical structures of individual patients, offering unprecedented precision and personalization. Benefits of 3D-printed implants include improved fit and comfort, reduced risk of infection, and enhanced recovery times. Perhaps most compelling is the ability to create complex structures that conventional manufacturing processes cannot achieve. This capability expands the possibilities for medical applications, enabling the production of highly specialized components such as customized joint replacements and cranial plates.

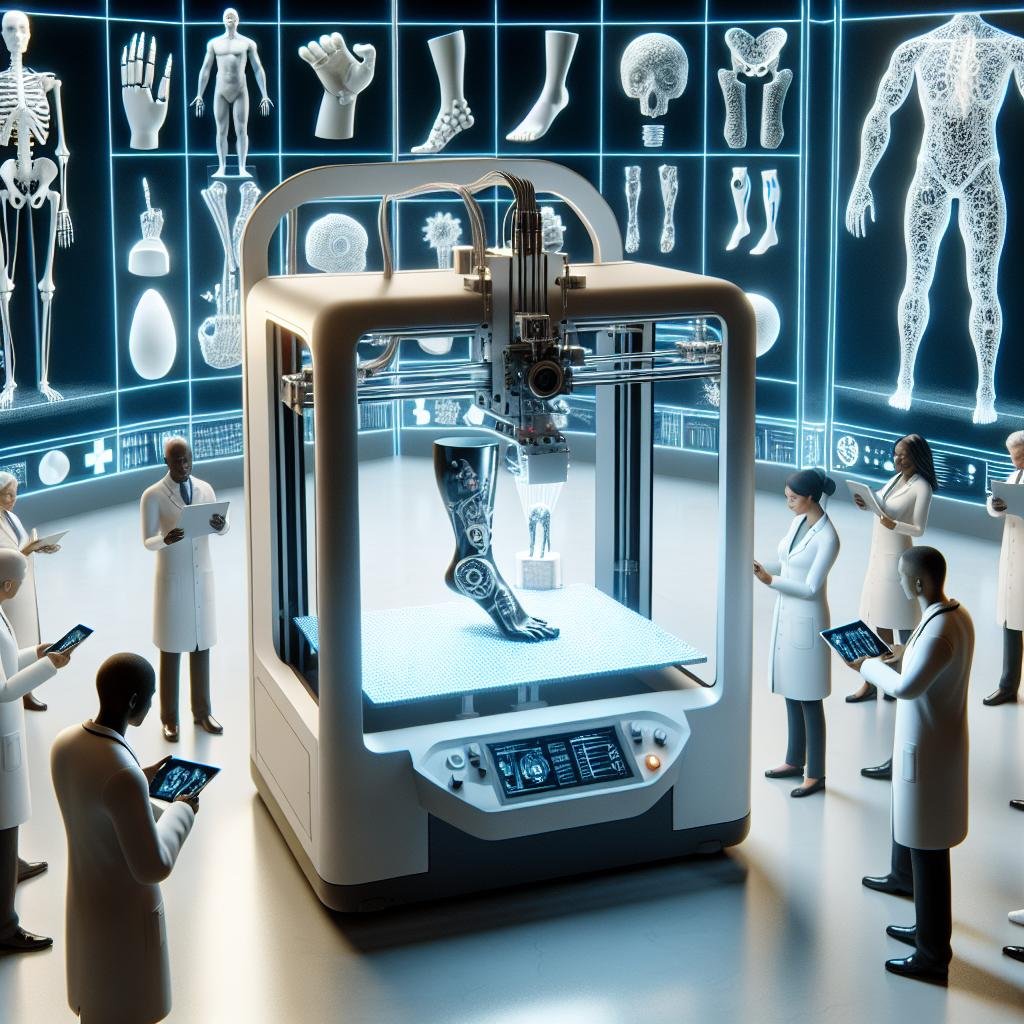

Moreover, the versatility of 3D printing in medical applications is highlighted through various materials and techniques used to ensure biocompatibility and functionality. Common methods include Fused deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS), each offering distinct advantages depending on the implant requirements. Below is a breakdown of materials and their uses:

| Material | Common Use |

|---|---|

| Titanium | Bone implants for hips and knees |

| PMMA (polymethyl Methacrylate) | Cranial plates |

| PCL (Polycaprolactone) | Soft tissue scaffolds |

The blend of innovative techniques and diverse materials not only fuels the potential for better patient outcomes, it also opens the door for more widespread and cost-effective healthcare solutions. As the medical community continues to harness these cutting-edge technologies, the future of custom medical implants is poised to reshape medical care as we certainly know it.

Empowering Surgeons: The Marvel of Customized Medical Solutions

In the realm of modern medicine, 3D printing stands as a beacon of innovation, transforming the landscape of surgical procedures with its ability to create customized implants that fit patients with unparalleled precision. Surgeons are now empowered to move beyond the one-size-fits-all approach, delving into the realms of tailored solutions that meet individual patient needs. Imagine a scenario where a previously unthinkable complexity of anatomical dimensions is digitally crafted with remarkable precision, enabling an implant that integrates seamlessly into the body. This marvel not only enhances surgical outcomes but also facilitates faster recovery and improved patient satisfaction by integrating with the body’s own contours.

The magic of 3D printing manifests through several key advantages:

- Personalization: Each implant is designed to the patient’s anatomy.

- Reduced surgery Time: Pre-designed implants lead to quicker surgeries.

- Innovative Materials: Utilization of biocompatible materials ensures safety and effectiveness.

- Enhanced Recovery: Custom fits often result in less discomfort post-operation.

| Aspect | traditional Implants | 3D printed Implants |

|---|---|---|

| Fit | generic | Custom-tailored |

| Production time | Long | Reduced |

| Customization | Limited | High |

Navigating Challenges: Strategies for a Seamless Implant Creation Process

In the ever-evolving field of medical technology, the creation of custom medical implants is no easy feat. Your journey from concept to creation can be fraught with challenges that range from design complexities to material selection. However, thanks to the cutting-edge capabilities of 3D printing, these hurdles can be navigated more seamlessly than ever. One of the key strategies is to embrace the adaptability that 3D printing offers. Unlike traditional manufacturing methods, 3D printing facilitates rapid prototyping and allows for an iterative design process, making it easier to refine structures with precision. Start by leveraging digital modeling tools to create detailed and customizable designs and utilize patient-specific data to yield implants that cater to individual anatomical requirements. This not only improves the fit and function of the implants but also enhances patient outcomes.

another strategic approach is the utilization of a wide range of biocompatible materials that 3D printing supports, allowing for more personalized and effective implants. The choice of materials significantly affects the performance and safety of the implant. Here’s a compact guide to help prioritize the most suitable materials:

| Material | Benefits |

|---|---|

| Titanium | High strength-to-weight ratio, biocompatibility |

| PCL | Supports bone growth |

| PEEK | Radiolucency and wear resistance |

Mastering these strategies can significantly streamline the implant creation process. Additionally, create a robust collaboration with multidisciplinary teams, including surgeons, engineers, and material scientists, to address potential challenges efficiently, ensuring a smooth journey from idea to implant. Remember, each step in the process is an opportunity for innovation and advancement.

Q&A

Q&A: Exploring the Wonders of 3D Printing in Custom Medical Implants

Q1: What exactly is 3D printing and how does it relate to medical implants?

A1: Imagine a machine that can create a three-dimensional object layer by layer, like a high-tech baker crafting a complex cake! That’s 3D printing in a nutshell. In the context of medical implants, it means making custom, patient-specific implants that perfectly fit an individual’s unique anatomy using this cutting-edge technology.

Q2: Why is customization in medical implants important?

A2: picture trying to fit into a one-size-fits-all shoe that doesn’t quite match your foot shape—not comfy, right? Similarly, our bodies are all wonderfully diffrent, and custom implants ensure a perfect fit, improving comfort and functionality. This personalized approach leads to better outcomes and happier patients!

Q3: How has 3D printing changed the game for medical professionals?

A3: It’s like giving doctors and surgeons a magic wand! With 3D printing, they can work with precise models of a patient’s anatomy before surgery, improving planning and execution. This leads to shorter surgeries, reduced risks, and faster healing times, all of which are music to any patient’s ears.

Q4: Are there any cool examples of custom implants created through 3D printing?

A4: Absolutely! From custom hip joints and cranial plates to dental implants and even tiny ear ossicles, 3D printing has been at the forefront of creating life-changing solutions. One especially heartwarming story involves a 3D-printed titanium sternum implant that transformed a cancer survivor’s life, fitting snugly and restoring her quality of life.

Q5: What challenges does 3D printing face in the medical field?

A5: Like any superhero,3D printing has its kryptonite. Challenges include ensuring material biocompatibility, meeting strict regulatory standards, and addressing the high cost of technology. However, with ongoing research and innovation, these hurdles are slowly being overcome.

Q6: What’s the future of 3D printing in the realm of medical implants?

A6: The future is as luminous as a sunny day! As the technology advances,we can expect even more impressive feats,such as bioprinting organs and utilizing smart materials that adapt to bodily changes. The hope is that someday, healthcare will be entirely customizable, accessible, and faster than ever before.

Feel free to reach out with any more curiosities or questions! This world of 3D printing in medical implants is evolving, and it’s an exciting journey to be a part of.

In Summary

As we wrap up our exploration into the fascinating world of 3D printing in custom medical implants, it’s clear that we’re witnessing a notable shift in the healthcare landscape. This innovative technology is not just transforming how we approach medical challenges, but it’s bridging the gap between what exists and what is possible. With every layer meticulously printed and every implant customized to perfection, we’re realizing a future where healing is more personalized, more efficient, and ultimately, more human.

Imagine a world where implants are tailor-made to fit each individual’s unique anatomy, where recovery times shrink, and where patient outcomes soar. This isn’t just a dream; it’s a reality being shaped layer by layer through the magic of 3D printing. As medical professionals, engineers, and patients continue to collaborate, we can look forward to a future brimming with hope and potential.

so, the next time you hear the buzz of a 3D printer, remember: it’s not just printing an object; it’s crafting a future where our bodies receive the bespoke care they deserve. Here’s to a world where technology and compassion go hand in hand, creating solutions that are as remarkable as they are life-changing. Until next time, keep dreaming big and staying curious!