Are you curious about the fascinating world of 3D printing? Whether you want to explore it as a hobby or unleash your creativity for professional purposes, getting started may seem overwhelming. But fear not! In this article, we will guide you through the essential steps and provide you with valuable tips to embark on your 3D printing journey with confidence. From choosing a reliable printer to finding the right software, you’ll be equipped with the knowledge and tools to turn your ideas into tangible objects. So, let’s dive in and discover how you can easily get started with 3D printing!

This image is property of i.all3dp.com.

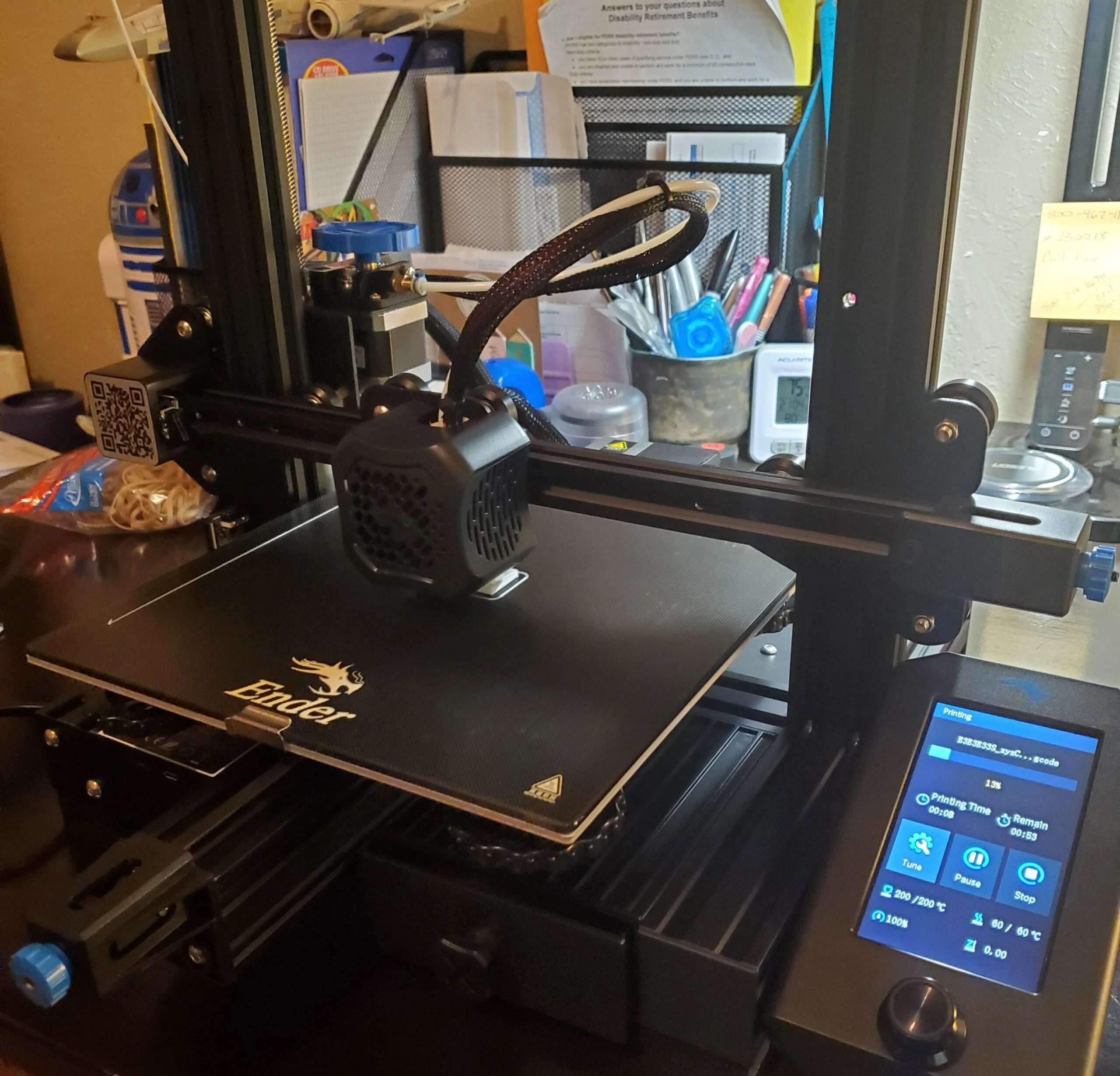

Choosing the Right 3D Printer

When it comes to choosing the right 3D printer, there are a few factors to consider. Firstly, you should think about your budget. 3D printers can vary significantly in price, so it’s important to determine how much you are willing to invest in this new hobby or profession. Next, define your printing needs. Are you planning to use the printer for personal projects or professional purposes? Knowing what you want to achieve with your 3D printer will help guide your decision-making process.

Once you have a clear idea of your budget and printing needs, it’s time to research different printer types. There are various technologies available, such as FDM (Fused Deposition Modeling), SLA (Stereolithography), and SLS (Selective Laser Sintering), each with its own advantages and limitations. Understanding the differences between these technologies will help you make an informed decision.

Another important factor to consider is the build volume of the printer. The build volume refers to the maximum size of objects that the printer can produce. If you have plans for larger prints, you’ll need a printer with a larger build volume. On the other hand, if you primarily want to create smaller objects, a printer with a smaller build volume may be more suitable.

Lastly, evaluate the available features of different 3D printers. Some printers come with additional functionalities like dual extruders for multi-color or multi-material printing, automatic bed leveling, or wireless connectivity. Think about which features are important to you and prioritize accordingly.

Understanding the Basics

Before diving into the world of 3D printing, it’s crucial to understand some basic concepts. First and foremost, learn about CAD (Computer-Aided Design) software. CAD software allows you to create precise, digital models that can be converted into 3D printable files. Familiarize yourself with popular CAD software options and choose one that suits your needs and skill level.

Next, get to know various 3D file formats. Common formats include STL (Standard Tessellation Language) and OBJ (Object File). These files contain the 3D model’s data and are required for 3D printing. Understanding the differences between file formats will help you efficiently manage your digital designs.

Another key concept to grasp is slicing. Slicing refers to the process of converting a 3D model into a series of 2D layers that the printer can understand. This involves setting parameters like layer height, print speed, and infill density. Understanding the slicing process is crucial for achieving successful prints.

Lastly, familiarize yourself with printer terminology. Get to know terms like extruder (the part that melts and deposits the filament), bed leveling (ensuring the print bed is perfectly aligned), and raft (a bottom layer that helps with adhesion). This knowledge will be invaluable as you navigate the world of 3D printing.

This image is property of www.momentier.com.

Setting Up Your Workspace

Creating a suitable workspace is essential for a smooth and enjoyable 3D printing experience. Start by finding a location for your printer that is convenient and well-suited for your needs. Consider factors such as accessibility, lighting, and noise levels. You’ll want a location that allows you to easily monitor and interact with the printer during the printing process.

Proper ventilation is also crucial. Some 3D printing materials can emit fumes that may be harmful if inhaled. Ensure that your workspace is well-ventilated, either by using a dedicated ventilation system or by opening windows and using fans to create a cross breeze.

Organizing necessary tools and materials is the next step. You’ll want to have essential tools like tweezers, pliers, and an assortment of screwdrivers on hand. Additionally, stock up on filament spools in various colors and materials. It’s always good to have a selection at your disposal.

Lastly, prepare a sturdy surface for the printer. 3D printers can be quite heavy, so make sure your surface can handle the weight and won’t wobble or vibrate during the printing process. A flat, level surface is crucial for achieving accurate prints.

Gathering Essential Supplies

In order to start your 3D printing journey, you’ll need to gather some essential supplies. The first step is choosing the right filament material. Filament is the material that is melted and extruded by the 3D printer to create the finished object. Common filament materials include PLA (Polylactic Acid), ABS (Acrylonitrile Butadiene Styrene), and PETG (Polyethylene Terephthalate Glycol).

Once you have chosen the filament material, make sure to stock up on filament spools. Running out of filament mid-print can be frustrating, so it’s always a good idea to have a few spares ready.

Cleaning tools are also necessary for maintaining your printer and ensuring quality prints. Tools such as needle nose pliers, wire cutters, and a brush are useful for removing and cleaning support structures from printed objects.

Bed adhesion materials are important for ensuring that your prints stick to the build surface. Depending on the type of printer you have, you may need to use materials like blue painter’s tape, glue stick, or a specialized printing surface like BuildTak.

Finally, consider acquiring additional accessories that can enhance your 3D printing experience. Accessories like a filament dryer, filament storage containers, and an enclosure to regulate temperature can all contribute to better print results.

This image is property of Amazon.com.

Installing and Configuring the Printer

Once you have your 3D printer, it’s time to set it up and get it ready for printing. Follow the manufacturer’s instructions for assembly, as each printer has its own unique assembly process. Take your time and carefully follow the steps to ensure everything is properly aligned and connected.

Next, connect your printer to your computer or network. This will allow you to send print files to the printer and control its settings. Follow the instructions provided by the manufacturer to establish the connection.

Install the required printer software on your computer. This software will enable you to communicate with the printer, control settings, and send print files. Most printers come with their own software, but there are also many third-party options available.

Before you start printing, it’s important to calibrate the printer. Calibration involves adjusting various settings to ensure that the printer is properly calibrated and ready to produce high-quality prints. Follow the instructions provided by the manufacturer for accurate calibration.

After calibrating the printer, it’s time to adjust the settings and preferences to meet your specific needs. Settings like print speed, layer height, and infill density can all be customized to achieve the desired print quality and strength.

Creating your First 3D Design

Now that your printer is installed and configured, it’s time to create your first 3D design. Start by picking a design software that suits your skill level and requirements. There are various options available, ranging from beginner-friendly software to more advanced programs used by professionals.

When starting out, it’s best to begin with simple projects. This allows you to become familiar with the design software and learn the basics of creating 3D models. Start by experimenting with basic shapes and gradually progress to more complex designs as your skills improve.

Before diving into the design process, it’s helpful to plan out your design in advance. Consider the dimensions, features, and functionality of the object you want to create. Create a rough sketch or have a clear mental image of the final product to guide your design process.

If necessary, take measurements of the object you want to recreate. This will ensure that your final design accurately reflects the desired dimensions. Use a caliper or ruler to measure length, width, and height.

As you begin creating your design, don’t be afraid to experiment. Working with basic shapes and making modifications will help you understand the capabilities of the design software and allow you to unleash your creativity.

This image is property of Amazon.com.

Preparing and Slicing the Model

Once you have created your 3D design, it’s time to prepare it for printing. Import the 3D model into a slicing software. Slicing software allows you to configure various parameters and generate the instructions that the printer needs to create the object layer by layer.

Position and scale the model within the slicing software to ensure it fits within your printer’s build volume. If the model is too large, you may need to resize or split it into multiple parts that can be printed separately and assembled later.

Set the printing parameters in the slicing software. This includes settings such as layer height, print speed, filament type, and print temperature. Experimenting with different settings will help you achieve the desired print quality.

If your design requires support structures to be printed, generate them within the slicing software. Supports are temporary structures that provide stability to overhanging or complex parts of the print. The software will automatically generate support structures based on your chosen settings.

Printing your Model

With the model prepared and sliced, it’s time to start printing. Make sure that your printer is properly set up and ready to go. Ensure that the print bed is clean and level, and that the extruder is loaded with the correct filament.

Load the filament into the printer according to the manufacturer’s instructions. Different printers have different methods for loading filament, so make sure to follow the specific guidelines for your printer model.

Initiate the print job either from your computer or directly from the printer’s interface. Double-check that all settings and parameters are correct before starting the print. Once the print job begins, monitor the progress to ensure everything is running smoothly.

During the printing process, it’s important to keep an eye out for any issues or errors that may arise. If the print is not adhering properly to the bed or if there are issues with the filament flow, it may be necessary to make adjustments or perform troubleshooting steps. Refer to the printer’s manual or seek assistance from online communities for guidance.

This image is property of d4804za1f1gw.cloudfront.net.

Post-Processing and Finishing Touches

Once the printing is complete, it’s time to remove the print from the build surface. Carefully remove the object, taking care not to damage it or the printer. Different printing surfaces may require different techniques for removing the print, so familiarize yourself with the specific instructions for your printer.

After removing the print, you may need to trim off excess support material. Use a combination of tools such as pliers, wire cutters, and sandpaper to remove any unwanted support structures and achieve a clean final result.

Perform necessary cleaning and sanding to refine the appearance of your print. Use soft brushes, sandpaper, and various cleaning solutions to remove any debris or imperfections. Take your time and be gentle to avoid damaging the print.

If desired, apply finishes or paints to enhance the appearance of the print. This can be done using techniques such as sanding, priming, and painting. Experiment with different finishes and colors to achieve the desired aesthetic.

Continuing to Learn and Improve

3D printing is a constantly evolving field, and there is always more to learn. To further enhance your skills and knowledge, experiment with different materials and settings. Try printing with different filaments to see how they affect the print quality, strength, and appearance. Adjust settings like print speed and temperature to optimize the results.

As you gain confidence in your 3D printing abilities, consider expanding your design skills. Learn new techniques and explore more complex designs. Challenge yourself to create intricate and functional objects that push the boundaries of what is possible with 3D printing.

Seek out online resources and tutorials to continue your education. There is a wealth of information available, ranging from video tutorials to written guides. Join 3D printing communities and forums to connect with other enthusiasts, share experiences, and seek advice and guidance.

Lastly, stay updated on the latest trends and advancements in the world of 3D printing. Subscribe to newsletters, follow industry blogs, and attend trade shows or conferences to stay informed. Being aware of the latest technologies and techniques will ensure that you continue to grow and improve as a 3D printing enthusiast or professional.

With these steps and a friendly approach, you are well on your way to getting started with 3D printing. Embrace the excitement and potential of this innovative technology, and let your creativity soar!