Imagine a future where organs can be printed on-demand, customized to patients’ specific needs. This is not just a far-fetched idea from a science fiction movie, but a reality that is rapidly advancing with the use of 3D printing technology in the field of medicine. With countless applications ranging from prosthetics to tissue engineering, 3D printing is revolutionizing the way we approach healthcare. In this article, we will explore the advancements and applications of 3D printing in medicine, offering a glimpse into the incredible potential it holds for improving patient care and treatment outcomes.

Customized Implants

Orthopedic implants

Orthopedic implants play a crucial role in the treatment of musculoskeletal injuries and conditions. With advancements in 3D printing technology, orthopedic implants can now be customized to fit each patient’s specific anatomy. This personalized approach not only enhances the effectiveness of the implants but also reduces the risk of complications and improves patient outcomes. Whether it is a hip replacement, knee implant, or spinal fusion device, 3D printing allows for the creation of implants that perfectly match the patient’s unique bone structure and alignment, resulting in improved mobility and comfort.

Dental implants

Dental implants have revolutionized the field of dentistry by providing a permanent solution for replacing missing teeth. 3D printing technology has further advanced the field by enabling the fabrication of customized dental implants. Traditional dental implants often require multiple visits to the dentist and time-consuming procedures. However, with the use of 3D printing, dental implants can now be designed, manufactured, and placed in a single session, significantly reducing the treatment time for patients.

Craniofacial implants

Craniofacial implants are used to reconstruct and restore the appearance and functionality of areas affected by facial trauma, congenital deformities, or cancer. 3D printing has revolutionized craniofacial implant surgery by allowing surgeons to create highly accurate and patient-specific implants. By utilizing detailed imaging data, 3D printing enables the production of implants that seamlessly integrate with the patient’s existing facial features. This level of customization not only improves the aesthetic outcome for patients but also enhances their quality of life.

Surgical Guides

Orthopedic surgery

Orthopedic surgery often involves complex procedures and requires utmost precision. 3D printing technology has introduced surgical guides that aid orthopedic surgeons in accurately planning and executing procedures. These guides are created based on the patient’s unique anatomy and provide a visual reference during surgery, ensuring precise incisions and implant placements. Surgical guides enhance surgical accuracy, reduce operating time, and minimize the risk of complications, ultimately leading to improved patient outcomes.

Dental surgery

Dental surgery, including procedures such as tooth extractions and dental implant placements, can be challenging due to the intricate nature of the oral cavity. 3D printed surgical guides have transformed the field of dental surgery by assisting dentists in performing precise and minimally invasive procedures. These guides are designed based on digital scans of the patient’s mouth, allowing for precise implant positioning and guided osteotomies. By using surgical guides, dentists can optimize treatment planning, reduce operative time, and achieve predictable surgical outcomes.

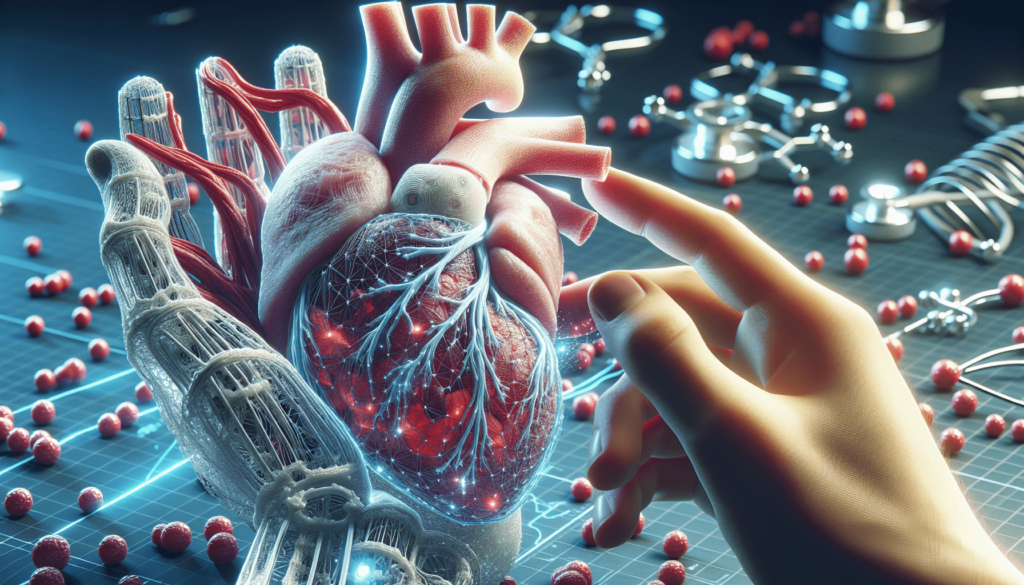

Cardiovascular surgery

Cardiovascular surgery requires utmost precision and careful planning to address conditions such as cardiac malformations and vascular diseases. 3D printed surgical guides have revolutionized the field by providing surgeons with detailed anatomical models that help in surgical planning. By accurately replicating the patient’s cardiovascular system, surgeons can visualize complex anatomical structures, practice procedures, and evaluate potential complications before entering the operating room. This technology enables surgeons to make informed decisions, improve patient safety, and enhance surgical outcomes in cardiovascular procedures.

Anatomical Models

Medical education

3D printing technology has transformed medical education by allowing students and healthcare professionals to have hands-on experience with anatomical models. These models accurately represent human anatomy, allowing for a more comprehensive understanding of the body. From individual organs to complex systems, 3D printed anatomical models provide a tangible and interactive learning experience, improving knowledge retention and enhancing surgical training.

Surgical planning

Preoperative surgical planning plays a crucial role in ensuring successful outcomes. 3D printing has revolutionized surgical planning by providing surgeons with patient-specific anatomical models. By utilizing medical imaging data, surgeons can create 3D models that accurately depict the patient’s anatomy, enabling them to visualize the surgical procedure in detail. This helps surgeons anticipate challenges, tailor the surgical approach, and optimize outcomes. The use of 3D printed anatomical models in surgical planning improves accuracy, reduces operative time, and minimizes the risk of complications.

Patient communication

Explaining surgical procedures and treatment plans to patients can be challenging, especially when the concepts are complex or abstract. 3D printed anatomical models have greatly improved patient communication by providing tangible representations of the patient’s condition. Surgeons can use these models to visually demonstrate the planned procedure, explain potential risks, and address patient concerns. This interactive approach promotes patient engagement, facilitates shared decision-making, and enhances patient satisfaction and compliance.

Prosthetics and Orthotics

Prosthetic limbs

3D printing has revolutionized the field of prosthetics by enabling the production of personalized and cost-effective prosthetic limbs. Traditional prosthetic manufacturing involves intricate processes and lengthy lead times. However, with 3D printing, prosthetic limbs can be designed, customized, and manufactured in a fraction of the time. By utilizing 3D scanning technology, prosthetists can create digital models of the patient’s residual limb, which serve as a basis for 3D printed prosthetics that perfectly fit the individual. This customization improves comfort, functionality, and aesthetics, allowing individuals to regain their mobility and independence.

Orthotic devices

Orthotic devices, such as braces and splints, provide support and stability to individuals with musculoskeletal conditions or injuries. 3D printing has revolutionized orthotics by allowing for the production of customized devices that precisely fit the patient’s anatomical needs. By utilizing 3D scanning and modeling, orthotists can create orthotic devices that are specifically tailored to each patient’s unique body shape and condition. This level of customization improves fit, comfort, and overall effectiveness, leading to better patient outcomes and increased compliance.

Customized braces

Braces are commonly used to correct misalignments, support injured joints, or aid in the rehabilitation process. With the advent of 3D printing, braces can now be customized to fit the patient’s specific needs and offer enhanced functionality. Traditional braces often require manual adjustments and can be uncomfortable for the wearer. However, 3D printed braces can be designed based on precise measurements and the patient’s individual requirements, resulting in improved comfort and better treatment outcomes. Additionally, 3D printing allows for the integration of lightweight and breathable materials, further enhancing the overall experience for the wearer.

Tissue Engineering

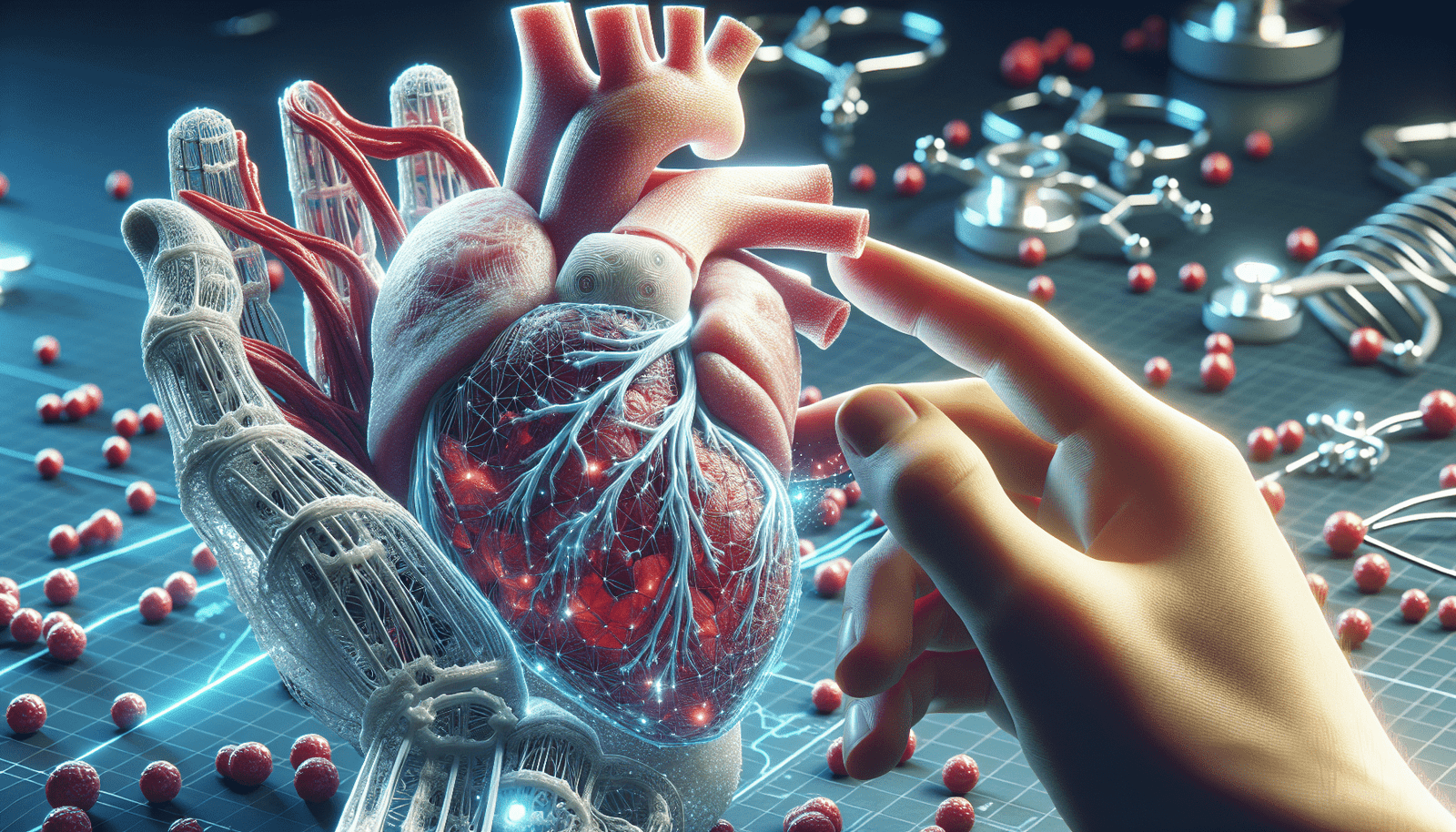

Organ transplantation

Organ transplantation is a life-saving procedure but faces challenges such as organ shortage and the risk of rejection. 3D printing has emerged as a promising technology in tissue engineering, offering a potential solution to these challenges. Through the use of biofabrication techniques and living cells, 3D printers can construct intricate structures that mimic native tissues and organs. This technology holds the promise of producing viable organs for transplantation, eliminating the need for donor organs and reducing the risk of rejection. Although significant research and development is still needed, 3D printing has the potential to revolutionize organ transplantation in the future.

Regenerative medicine

Regenerative medicine aims to restore or replace damaged tissues and organs through the use of stem cells, biomaterials, and growth factors. 3D printing has emerged as a valuable tool in regenerative medicine by enabling the fabrication of precise and complex structures. By incorporating bioactive compounds and cell-laden scaffolds, 3D printed constructs can promote tissue regeneration and accelerate healing. This technology holds tremendous potential in treating various conditions, such as bone defects, cartilage damage, and skin wounds, offering hope for patients who previously had limited treatment options.

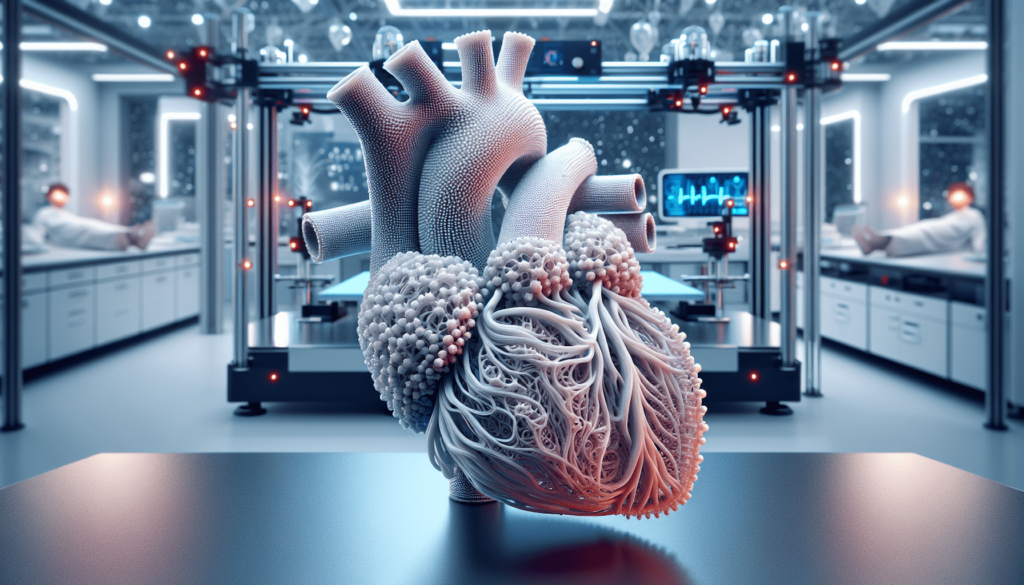

Biofabrication

Biofabrication refers to the use of 3D printing technology to create living tissues and organs. By utilizing biocompatible materials and cell cultures, biofabrication enables the precise deposition of cells to mimic native tissue structures. This field holds immense promise in tissue engineering, drug testing, and disease modeling. Through biofabrication, scientists can create tissue constructs that accurately replicate human anatomy and physiology, providing a platform for studying diseases and developing personalized treatment approaches. Although still in its early stages, biofabrication has the potential to transform healthcare by offering patient-specific and functional tissue constructs for regenerative medicine applications.

Drug Delivery Systems

Personalized medicine

Personalized medicine aims to tailor medical treatments to the individual characteristics of each patient. 3D printing has the potential to revolutionize drug delivery systems by enabling the production of personalized medications. With 3D printing, medications can be customized in terms of dosage, release rates, and formulation. By incorporating multiple medications into a single dosage form, 3D printed drug delivery systems can simplify complex medication regimens and improve patient compliance. This technology holds tremendous potential in optimizing drug therapies and enhancing treatment outcomes for individuals with specific physiological needs.

Controlled-release systems

Controlled-release systems play a vital role in delivering medications at a controlled rate over an extended period. 3D printing has the ability to precisely engineer such systems, offering advantages over traditional manufacturing methods. By using 3D printing, drug release profiles can be tailored through the design of intricate structures and the incorporation of porous materials. This level of control allows for precise dosing and targeted drug delivery, reducing side effects and improving therapeutic efficacy. Controlled-release systems created through 3D printing have the potential to transform drug delivery and improve patient outcomes in various medical conditions.

Implantable devices

Implantable devices, such as drug-eluting stents and sustained-release implants, have revolutionized medical treatments by providing localized and continuous drug delivery. 3D printing technology has played a significant role in advancing the design and development of implantable devices. By utilizing 3D printing, these devices can be customized to fit the patient’s specific anatomy and drug requirements. This customization improves biocompatibility, optimizes drug release, and minimizes the risk of complications. With 3D printed implantable devices, clinicians can deliver medications directly to the site of action, enhancing the effectiveness of treatment and improving patient outcomes.

Surgical Instruments

Patient-specific instruments

Surgical instruments play a crucial role in ensuring the accuracy and effectiveness of surgical procedures. With the advent of 3D printing technology, surgical instruments can now be customized to match the patient’s unique anatomy. This level of customization allows surgeons to perform procedures with enhanced precision and reduces the risk of errors. By utilizing detailed imaging data, 3D printed patient-specific instruments enable surgeons to accurately navigate complex surgical sites, optimize incision points, and improve overall surgical outcomes.

Complex instrument designs

3D printing has opened up new possibilities for designing complex surgical instruments that were previously challenging to manufacture using traditional methods. By utilizing the flexibility of 3D printing, intricate designs and structures can be created, enhancing instrument functionality and improving surgical precision. Complex instrument designs, such as specialized graspers, retractors, and cutting tools, enable surgeons to perform intricate procedures with ease and accuracy. The use of 3D printed complex instruments revolutionizes surgical techniques, allowing for minimally invasive approaches and reducing patient trauma.

Improved ergonomics

Ergonomics plays a crucial role in surgical procedures, as it affects both the surgeon’s comfort and the quality of surgical interventions. 3D printing technology has introduced the concept of ergonomic surgical instruments, which are tailored to fit the surgeon’s hand and promote optimal grip and dexterity. By customizing the shape, size, and texture of surgical instruments, 3D printing allows for improved tactile feedback and reduced fatigue during surgical procedures. Enhanced ergonomics not only improves surgical outcomes but also contributes to the overall well-being of the surgical team.

Bioprinting

Printing living cells

Bioprinting is an emerging field that combines 3D printing technology with living cells and biomaterials to create living tissue constructs. By utilizing bioinks that contain living cells, bioprinting enables the development of intricate tissue structures that closely resemble native tissues. This technology holds immense potential in regenerative medicine, as it allows for the creation of patient-specific tissue constructs for transplantation and drug testing applications. Bioprinting living cells represents a significant step forward in tissue engineering and has the potential to transform the fields of medicine and patient care.

Creating organoids

Organoids are miniature organ-like structures that are derived from stem cells and closely mimic the architecture and functionality of specific organs. 3D printing has revolutionized the creation of organoids by providing a platform for precise and controlled cell deposition. By utilizing bioinks containing organ-specific cell populations, 3D printers can construct complex organoids that can be used for disease modeling, drug testing, and personalized medicine. The ability to create organoids through 3D printing has immense potential in advancing our understanding of organ development and disease progression, ultimately leading to improved treatment strategies.

Development of artificial organs

The shortage of donor organs continues to be a significant challenge in transplantation medicine. 3D printing has emerged as a potential solution by offering the ability to create artificial organs. By utilizing a patient’s own cells and 3D printing technology, researchers can construct bioengineered organs that can be used for transplantation. Although still in its early stages, the development of artificial organs holds tremendous promise in addressing the organ shortage crisis and reducing the risk of rejection. 3D printing has the potential to revolutionize the field of organ transplantation and significantly improve the quality of life for patients in need.

Surgical Simulation

Training and practice

Surgical simulation allows surgeons to train and practice complex procedures in a controlled and safe environment. 3D printing has transformed surgical simulation by providing realistic and patient-specific anatomical models that replicate human tissues and organs. Surgeons can practice procedures multiple times and refine their skills before performing them on actual patients. This technology not only improves the surgeon’s proficiency but also enhances patient safety by minimizing the risk of errors during surgical interventions.

Virtual reality integration

Virtual reality (VR) integration in surgical simulation has further enhanced training opportunities for surgeons. By combining 3D printed anatomical models with VR technology, surgeons can immerse themselves in a realistic surgical environment, gaining a deeper understanding of spatial relationships and improving hand-eye coordination. Virtual reality integration allows surgeons to simulate complex procedures, practice challenging scenarios, and develop innovative techniques in a risk-free setting. This advanced training approach has the potential to revolutionize surgical education and improve patient outcomes.

Evaluating new techniques

The constant evolution of surgical techniques and equipment introduces the need to evaluate their safety and effectiveness before widespread clinical adoption. 3D printing offers a valuable tool for evaluating new techniques by providing accurate, personalized anatomical models that can be used for preoperative planning and testing. Surgeons can simulate procedures on 3D printed models, evaluate the feasibility of new techniques, and make informed decisions regarding their implementation. The ability to evaluate new techniques using 3D printed models improves patient safety, reduces the learning curve for surgeons, and ensures the adoption of evidence-based practices.

Regulatory Challenges

Quality control

As 3D printing becomes increasingly integrated into medical practice, ensuring the quality and safety of printed medical devices and implants poses significant regulatory challenges. There is a need for robust quality control measures to guarantee that 3D printed products meet strict standards and perform as intended. Key considerations for quality control include material biocompatibility, dimensional accuracy, strength, and sterility. Regulatory authorities and industry leaders must collaborate to establish comprehensive guidelines and standards to govern the manufacturing processes, post-processing techniques, and quality assurance procedures associated with 3D printed medical products.

FDA approval

Obtaining regulatory approval from the United States Food and Drug Administration (FDA) for 3D printed medical devices and implants can be a complex and time-consuming process. The FDA evaluates the safety and effectiveness of these products based on rigorous testing and assessment. Manufacturers must provide substantial evidence to demonstrate product safety, including biocompatibility, mechanical performance, and long-term stability. The FDA plays a crucial role in ensuring that 3D printed medical products meet the highest standards of quality and effectiveness before they can be used in clinical settings.

Ethical considerations

The rapid advancement of 3D printing technology in medicine raises important ethical considerations. As the ability to create customized implants, tissues, and organs becomes more accessible, ethical questions regarding patient selection, resource allocation, and informed consent arise. Striking a balance between the potential benefits of 3D printing in medicine and the ethical implications it entails is essential. Collaboration between healthcare professionals, policymakers, and ethicists is necessary to address these ethical considerations and ensure that the integration of 3D printing in medicine aligns with patient autonomy, equity, and safety.