Have you ever wondered about the environmental impact of 3D printing? As this innovative technology continues to gain popularity, it’s important to consider how it affects our planet. From the materials used in printing, to the energy consumed during the process, 3D printing has both positive and negative implications for the environment. In this article, we’ll explore the various ways 3D printing impacts the environment, and discuss potential solutions to minimize its carbon footprint. So, grab a cup of coffee and join us as we explore the fascinating world of 3D printing and its environmental impact.

This image is property of ars.els-cdn.com.

1. Resource Consumption

1.1 Raw Material Usage

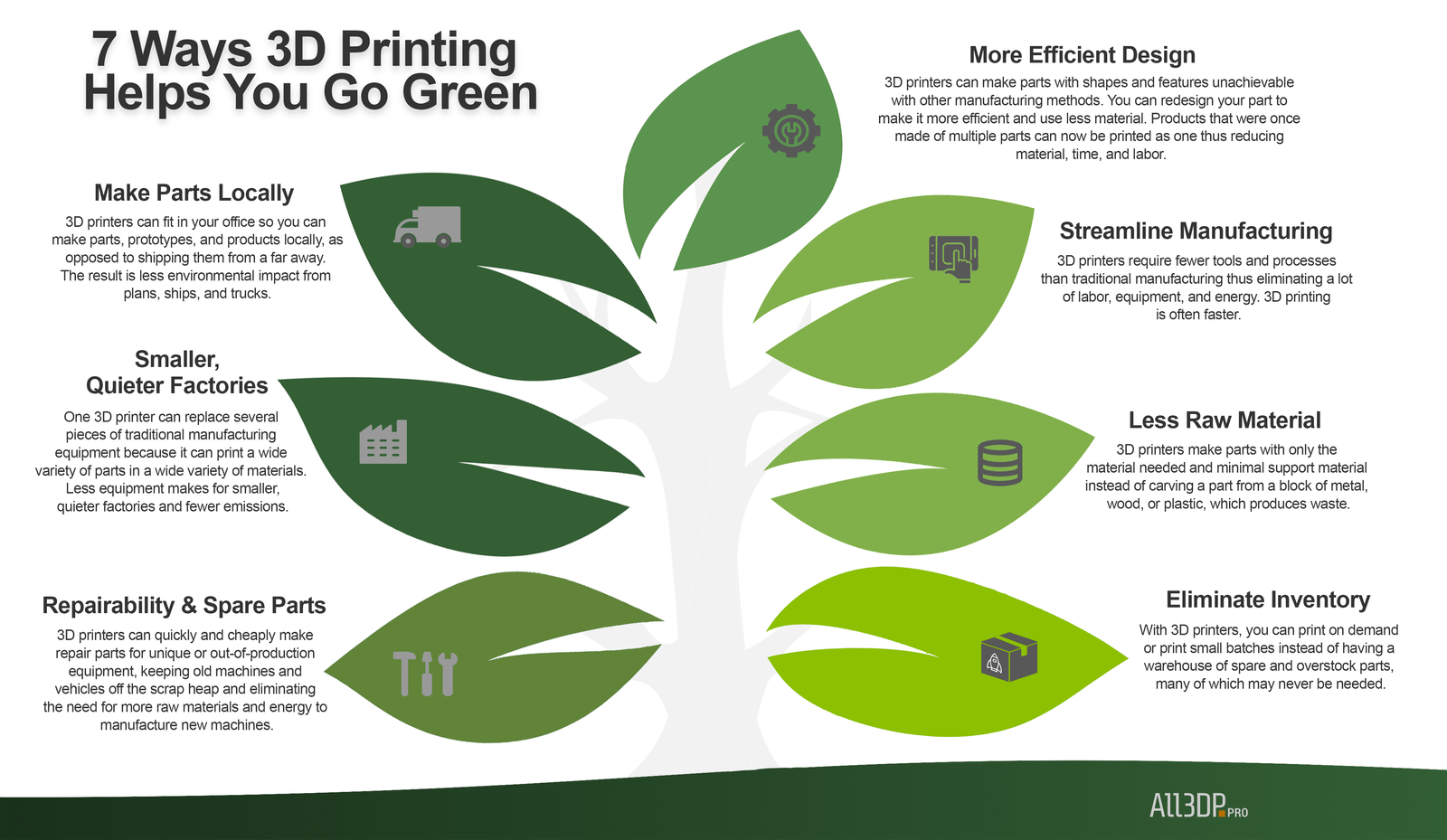

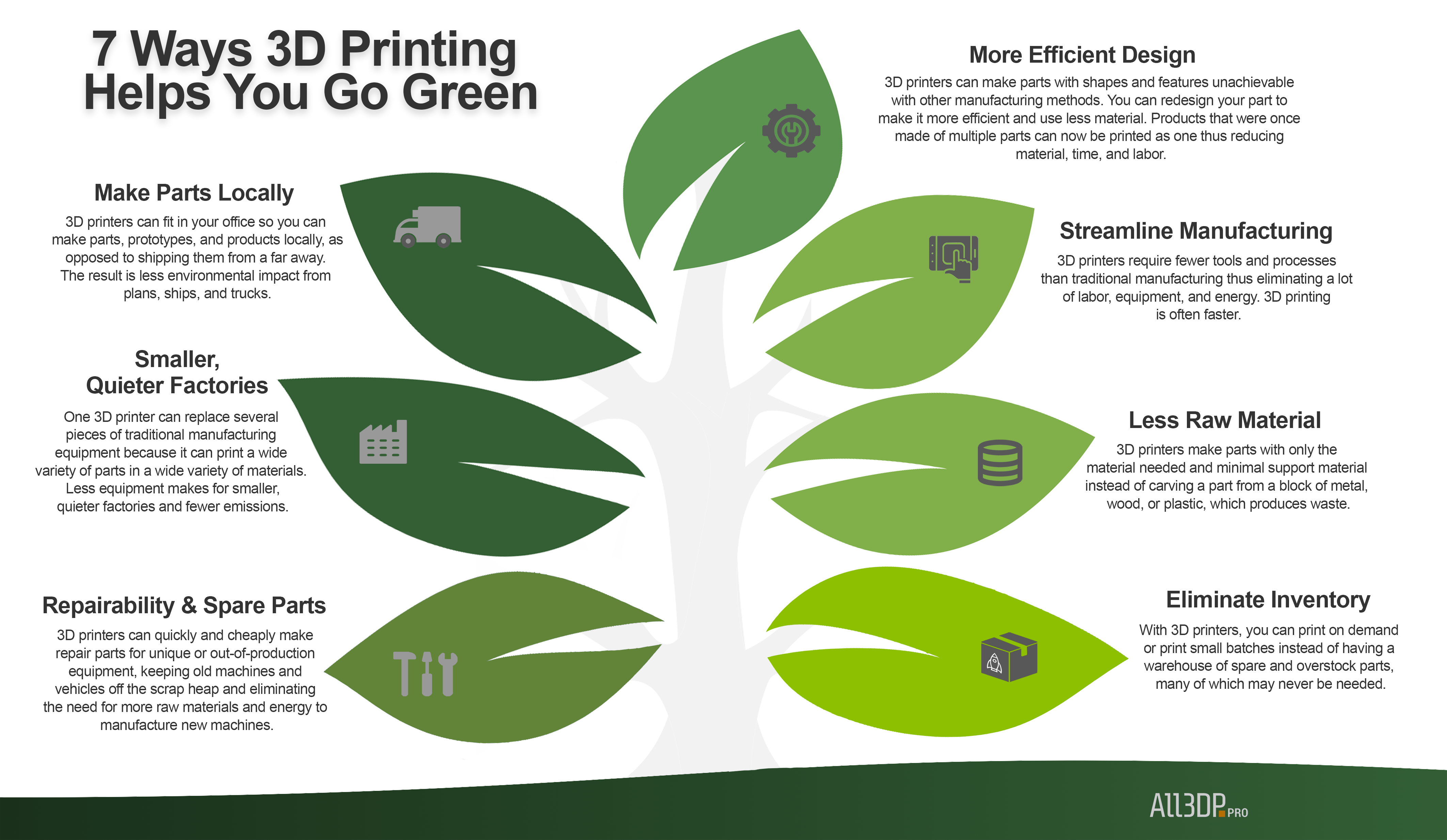

When it comes to resource consumption, one of the key concerns in 3D printing is the usage of raw materials. Traditional manufacturing processes often generate a significant amount of waste, but with 3D printing, materials can be used more efficiently. The technology allows for precise and targeted material deposition, minimizing waste and optimizing material usage. This means that less raw material is required compared to conventional manufacturing methods, making 3D printing a more sustainable option.

1.2 Energy Consumption

In addition to raw material usage, energy consumption is another important factor to consider when evaluating the environmental impact of 3D printing. The energy requirements for 3D printing vary depending on the specific technology used, but overall, it can be a more energy-efficient process compared to traditional manufacturing. With the ability to create complex geometries and intricate designs in a single process, 3D printing can reduce the need for multiple manufacturing steps, ultimately saving energy in the production process.

2. Waste Generation

2.1 Plastic Waste

One of the main concerns when it comes to waste generation in 3D printing is the accumulation of plastic waste. Many 3D printers use thermoplastic materials, such as ABS or PLA, which can be difficult to recycle. The disposal of plastic waste can have a detrimental impact on the environment, contributing to pollution and harming wildlife. To mitigate the environmental impact of plastic waste from 3D printing, it is essential to explore recycling options and develop more sustainable, biodegradable materials.

2.2 Hazardous Waste

Another aspect to consider regarding waste generation in 3D printing is the production of hazardous waste. Some 3D printing technologies, such as stereolithography, involve the use of liquid resins that may contain toxic or harmful chemicals. Proper handling, storage, and disposal of this hazardous waste are crucial to minimize its impact on the environment. Implementing responsible waste management practices and exploring alternative materials that are safer and more environmentally friendly can help mitigate these concerns.

This image is property of www.tctmagazine.com.

3. Emissions

3.1 VOC Emissions

Volatile Organic Compounds (VOC) emissions are a significant concern when it comes to 3D printing. Certain printing materials, particularly those containing solvents, can generate VOCs during the printing process, which contribute to air pollution and have potential health risks. To address this issue, it is important to use materials with low VOC emissions and ensure proper ventilation in the printing environment. Implementing effective air filtration systems can further reduce the release of VOCs into the atmosphere and create a safer working environment.

3.2 Particulate Matter Emissions

Particulate matter emissions are another environmental concern associated with 3D printing. These tiny airborne particles can be released during the printing process, mainly when using materials like metal or resin. Particulate matter pollution can have adverse effects on air quality and human health, especially in enclosed spaces. To minimize particulate matter emissions, it is crucial to implement proper ventilation systems, use appropriate filtration methods, and consider the use of alternative materials that generate lower levels of particulate matter.

4. Energy Source

4.1 Renewable Energy Usage

One way to reduce the environmental impact of 3D printing is by utilizing renewable energy sources to power the printing process. Renewable energy, such as solar or wind power, can significantly reduce carbon emissions associated with energy consumption. By sourcing energy sustainably, 3D printing can become a more environmentally friendly manufacturing option.

4.2 Fossil Fuel Dependence

However, it is important to acknowledge that not all 3D printing operations currently rely on renewable energy sources. Many still depend on fossil fuels for their energy needs, which contribute to greenhouse gas emissions and climate change. As the demand for 3D printing continues to grow, it is crucial for the industry to transition towards renewable energy sources and reduce its reliance on fossil fuels.

This image is property of ars.els-cdn.com.

5. Supply Chain Impact

5.1 Transportation and Logistics

The environmental impact of 3D printing extends beyond the printing process itself and encompasses its entire supply chain. One aspect to consider is the transportation and logistics involved in the distribution of 3D printed products. While 3D printing enables localized manufacturing and reduces the need for long-distance transportation, there are still logistical aspects to address. Optimizing transportation routes and employing eco-friendly shipping methods can help mitigate the environmental impact of the supply chain.

5.2 Material Sourcing

Another significant consideration is the sourcing of materials used in 3D printing. Certain materials, such as rare metals or exotic polymers, may have a significant environmental impact due to the energy-intensive extraction processes or unsustainable harvesting practices. To minimize the environmental footprint, it is crucial to source materials responsibly, opting for sustainable alternatives whenever possible. Additionally, exploring the use of recycled materials can further reduce the impact of material sourcing on the environment.

6. Recycling and Reusability

6.1 Challenges in Recycling

Recycling in 3D printing can be a complex process due to various factors. Some materials used in 3D printing, such as mixed plastics, can be challenging to recycle efficiently. Additionally, the layer-by-layer printing approach can create materials with different properties, making it difficult to separate and recycle them effectively. Overcoming these challenges requires the development of innovative recycling technologies and the implementation of standardized recycling practices across the industry.

6.2 Promoting Reusability

Promoting reusability is another avenue towards reducing the environmental impact of 3D printing. By designing products with disassembly and reusability in mind, the lifespan of printed objects can be extended, helping to minimize waste generation. Additionally, encouraging the use of recycled materials and implementing closed-loop systems can further enhance the sustainability of 3D printing.

This image is property of i.all3dp.com.

7. Life Cycle Assessment

7.1 Material Extraction

The life cycle assessment of 3D printing begins with the extraction of the materials used. It is essential to evaluate the environmental impact of the extraction process, considering factors such as energy consumption, resource depletion, and the potential for ecosystem disturbance. Opting for materials with lower environmental footprints, exploring sustainable sourcing options, and minimizing the use of virgin materials can contribute to a more sustainable life cycle for 3D printed products.

7.2 Manufacturing Process

The manufacturing process itself also plays a crucial role in the environmental impact of 3D printing. As discussed earlier, optimizing material usage, reducing waste generation, and improving energy efficiency are key considerations to reduce the footprint of the manufacturing process. Using additive manufacturing technologies that consume less energy and exploring alternative materials and printing techniques can further enhance sustainability in this phase.

7.3 Use Phase

The use phase of 3D printed products also influences their environmental impact. Optimization of the design and structural integrity of the printed objects can contribute to longer lifespans, reducing the need for constant replacements or repairs. Additionally, designing products with energy-efficient operation in mind can help minimize energy consumption during their use.

7.4 End of Life

The end-of-life phase of 3D printed products is another important aspect to consider. Proper disposal and recycling of these products can minimize waste generation and the associated environmental impact. Implementing recycling systems, developing guidelines for end-of-life management, and exploring innovative methods for material recovery can contribute to a more sustainable approach to the disposal of 3D printed products.

8. Potential Solutions

8.1 Material Innovations

Innovation in materials is crucial for improving the sustainability of 3D printing. Developing new materials with lower environmental footprints, such as biodegradable polymers or recycled materials, can help reduce the impact of raw material usage, waste generation, and end-of-life disposal. Research and development efforts should focus on creating materials that are not only environmentally friendly but also offer the required mechanical properties and performance for various applications.

8.2 Energy Efficiency Measures

Improving energy efficiency in 3D printing can significantly reduce its environmental impact. Efficient printer designs, better control of heating and cooling systems, and the utilization of energy-saving technologies can all contribute to energy conservation. Additionally, implementing energy management systems and monitoring the energy usage of 3D printing operations can help identify areas for improvement and optimize energy consumption.

8.3 Closed-Loop Systems

Closed-loop systems aim to minimize waste and maximize material efficiency by recycling and reusing materials within the 3D printing process. By integrating material recovery and recycling systems into 3D printers, waste generation can be minimized, and the environmental impact can be reduced. Closed-loop systems can also contribute to cost savings and a more sustainable supply chain by reducing the need for new material sourcing.

This image is property of 3dprintingindustry.com.

9. Regulatory Framework

9.1 Legislation and Compliance

The development of a regulatory framework specific to 3D printing can play a crucial role in mitigating its environmental impact. Government agencies and regulatory bodies should work towards implementing legislation that promotes the use of sustainable materials, encourages energy-efficient practices, and establishes guidelines for waste management and recycling in the 3D printing industry. Compliance with these regulations will ensure that environmental considerations are prioritized and that sustainable practices become the norm.

9.2 Environmental Standards

Establishing environmental standards and certifications can help drive sustainability in the 3D printing industry. These standards can ensure that 3D printing operations meet specific environmental criteria and adhere to best practices. They can also provide consumers with the necessary information to make informed choices about sustainable products and encourage manufacturers to adopt more environmentally friendly practices.

10. Future Outlook

10.1 Advancements in Sustainable 3D Printing

The future of 3D printing holds promising advancements in sustainability. Researchers and manufacturers are continuously exploring new materials, printing techniques, and technologies to improve the environmental performance of 3D printing. Innovations such as bio-based materials, advanced recycling methods, and energy-efficient printers are expected to contribute to a more sustainable and environmentally friendly 3D printing industry.

10.2 Adoption and Awareness

As the awareness of the environmental impact of traditional manufacturing processes grows, so does the interest in sustainable alternatives like 3D printing. Increased adoption of 3D printing technologies can contribute to a more sustainable manufacturing industry. However, it is crucial to continue educating individuals and businesses about the environmental considerations associated with 3D printing, promoting responsible practices, and encouraging the adoption of sustainable approaches throughout the entire life cycle of 3D printed products.

In conclusion, while 3D printing offers numerous benefits, it is important to acknowledge and address its environmental impact. By considering resource consumption, waste generation, emissions, energy sources, supply chain impact, recycling and reusability, life cycle assessment, potential solutions, regulatory frameworks, and future outlook, we can work towards a more sustainable and environmentally friendly 3D printing industry. With continued research, innovation, and collective efforts, 3D printing has the potential to revolutionize manufacturing while minimizing its environmental footprint.