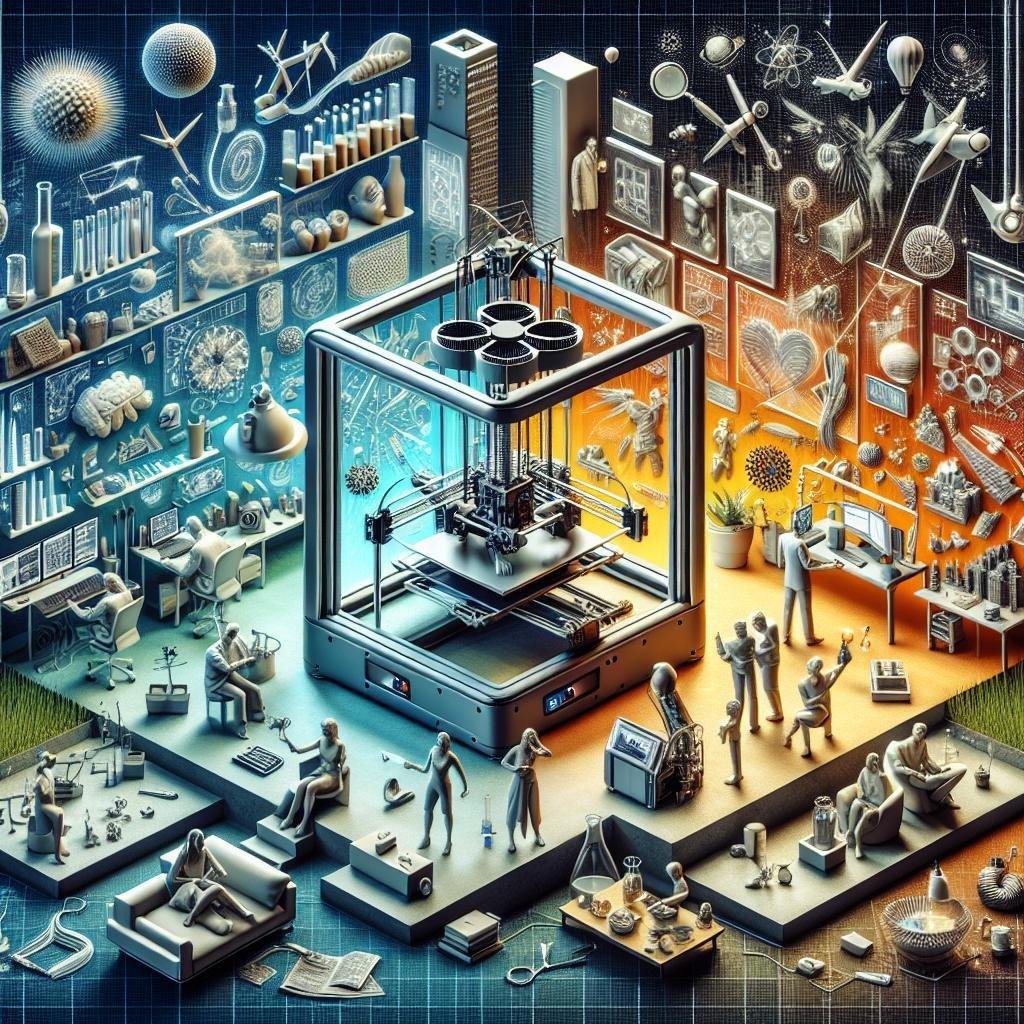

Imagine a world where you can bring your wildest creations to life with just the click of a button. No, we’re not talking about a fantastical future; we’re talking about the magical realm of 3D printing technology. Once a concept confined to the pages of science fiction, 3D printing has exploded into reality, capturing the imaginations of both curious hobbyists tinkering in their garages and seasoned professionals revolutionizing entire industries. But like any groundbreaking innovation, 3D printing comes with its own set of highs and lows. Whether you’re a weekend sculptor or an industry veteran, join us as we dive deep into the fascinating world of 3D printing, uncovering the pros and cons that could make—or break—your next big project. Fasten your seatbelts; it’s going to be a thrilling ride!

Choosing the Right 3D Printer: Quick Guide for Beginners and Experts

Whether you’re a beginner or a seasoned pro, navigating the sea of 3D printers can be a bit overwhelming. Understanding your specific needs and skill level is key. For beginners, simplicity and ease of use should be at the forefront. Look for printers with auto-leveling beds, user-friendly interfaces, and good customer support. Brands like Creality Ender and Anycubic Mega offer budget-friendly options with impressive features.

- Auto-Leveling Beds: Simplifies the printing process.

- User-Friendly Interfaces: Ensures a smooth learning curve.

- Good Customer Support: Offers help when needed.

On the other hand, experts might prefer models with more advanced capabilities and customizable settings. Consider printers that support multiple filament types, have large build volumes, and provide the ability to tweak nearly every setting. Brands like Prusa and LulzBot are often the go-to for professionals seeking high precision and reliability. Here’s a quick comparison to help delineate:

| Feature | Beginners | Experts |

|---|---|---|

| Filament Types | PLA, ABS | PLA, ABS, TPU, PETG |

| Build Volume | Small to Medium | Medium to Large |

| Customization | Limited | Extensive |

Materials and Filaments: Exploring Your Options for Creative Projects

Diving into the realm of 3D printing unveils a treasure trove of materials and filaments that cater to both the novice hobbyist and the seasoned professional. Each option brings its own set of characteristics, benefits, and quirks, influencing your project’s outcome. PLA (Polylactic Acid), for instance, stands out as a favorite among beginners due to its ease of use and biodegradable nature. ABS (Acrylonitrile Butadiene Styrene), on the other hand, offers robust durability and is excellent for functional parts but requires a heated bed and proper ventilation. For those looking to expand their creative horizons, PETG (Polyethylene Terephthalate Glycol) provides a sweet spot between PLA and ABS, offering strength along with ease of printing, making it ideal for more intricate designs.

Beyond the staple materials, the world of specialty filaments opens up endless possibilities. Enthusiasts can dabble with Wood-filled PLA for a unique, rustic finish on their prints or experiment with Metallic Filaments containing metal powders to achieve a genuine metallic appearance. For projects that demand flexibility, TPU (Thermoplastic Polyurethane) emerges as a stellar choice, providing prints with resilience and stretchability. Think beyond the basics and consider using Glow-in-the-Dark Filaments for creative, night-time displays or Conductive Filaments to craft interactive electronic components. Here’s a quick reference for some popular materials:

| Material | Key Characteristics |

|---|---|

| PLA | Eco-friendly, easy to print |

| ABS | Strong, durable, requires heated bed |

| PETG | Strong, easy to print, versatile |

| TPU | Flexible, resilient |

| Wood-filled PLA | Rustic finish, easy to print |

Mastering the Craft: Tips and Tricks for High-Quality 3D Prints

Elevating your 3D printing game involves a blend of meticulous preparation and innovative thinking. Ensuring that your models come out flawless, whether you’re a hobbyist crafting intricate miniatures or a professional prototyping futuristic designs, requires a keen attention to detail. Start by fine-tuning your slicing software settings—layer height, infill density, and print speed are crucial parameters that significantly impact the final outcome. Don’t shy away from experimenting with different filament materials; exploring options like PLA, ABS, PETG, or even exotic blends can unlock new potential for your prints.

Another expert tip is mastering bed adhesion techniques. Utilize tools such as blue painter’s tape, glue sticks, or PEI sheets to ensure a smooth first layer. Regularly calibrating your print bed and nozzle height cannot be overstated; an accurate Z-offset sets the stage for achieving razor-thin precision. Leveraging post-processing methods like sanding, priming, and painting can transform a good print into a masterpiece. For further optimization, ensure your printer firmware is up-to-date and consider implementing automatic bed leveling sensors to save time and enhance print consistency.

| Tool | Purpose |

|---|---|

| Blue Painter’s Tape | Improves bed adhesion |

| Glue Stick | Enhances first layer adhesion |

| PEI Sheet | Provides a reliable surface |

| Automatic Bed Leveling Sensor | Ensures uniform print height |

Navigating Pitfalls: Common Challenges and How to Overcome Them

Navigating the world of 3D printing can be exhilarating, yet it’s not without its set of challenges. For hobbyists, common pitfalls often include issues such as poor print quality and equipment malfunctions. Troubles with print adhesion or nozzle clogs can thwart even the most enthusiastic of creators. Overcoming these challenges requires a bit of patience and a lot of troubleshooting. A quick fix might involve tweaking temperature settings or experimenting with different types of filament. Investing some time in community forums or watching YouTube tutorials can also provide an abundance of tested solutions and creative hacks. Remember, the key is to try, fail, and learn—a continuous cycle that will eventually lead to mastery.

For professionals, the stakes are often higher, and the challenges more technical. Prototyping efficiency and material costs frequently top the list of concerns. Managing these requires strategic planning and resource allocation. For instance, professionals can optimize their workflow by using advanced slicing software that minimizes waste and reduces production time. Another effective approach might be to diversify the materials used. Instead of sticking only to high-cost filaments, consider utilizing a mix of economical and specialized materials based on project needs. Below is a quick comparison to help you balance cost and efficiency:

| Material | Cost | Application |

|---|---|---|

| PLA | Low | Prototyping, hobby projects |

| ABS | Moderate | Durable parts, mechanical objects |

| PEEK | High | High-performance engineering |

Balancing cost, quality, and application will streamline your operations and help you overcome these common professional hurdles.

Q&A

Article Title: 3D Printing Technology: Pros and Cons for Hobbyists and Professionals

Q&A Section

Q1: What’s all the buzz about 3D printing? Why is it so popular among hobbyists and professionals alike?

A1: Ah, the magic of 3D printing! Imagine being able to bring your wildest ideas to life, layer by delicate layer. For hobbyists, this means the freedom to create custom models, gadgets, and even cosplay items from the comfort of their home. Professionals, on the other hand, are drawn to 3D printing for its rapid prototyping capabilities, cost-efficiency, and the potential to innovate in fields like medicine, engineering, and fashion. It’s like having a tiny factory at your fingertips – what’s not to love?

Q2: Sounds like a dream! But surely there must be some downsides?

A2: Like all technologies, 3D printing has its drawbacks too. For starters, quality can sometimes be inconsistent, especially with lower-end printers. Post-processing (sanding, painting, etc.) can be time-consuming, and let’s not even get started on the occasional printer jams and filament tangles! For professionals, the initial investment in high-quality printers can be steep, and keeping up with the rapidly evolving technology can feel like a treadmill. But, hey, nothing great comes without a few challenges, right?

Q3: What kind of materials can you use with 3D printers? Are there differences between what hobbyists and professionals use?

A3: Absolutely, the material you choose can make a big difference. Hobbyists often use PLA (Polylactic Acid) due to its ease of use and biodegradable nature. It’s perfect for making simple models and fun gadgets. Professionals, meanwhile, might opt for more robust materials like ABS (Acrylonitrile Butadiene Styrene) or PETG (Polyethylene Terephthalate Glycol) for engineering prototypes, or even more advanced materials like TPU (Thermoplastic Polyurethane) for flexible parts and Nylon for industrial applications. The choice of material can drastically affect the final product’s durability, flexibility, and appearance.

Q4: I’m a total newbie. How easy is it to get started with 3D printing as a hobby?

A4: Welcome to the club! Getting started has never been easier (and more exciting). Today, entry-level 3D printers are more affordable and user-friendly than ever. There are plenty of online resources, communities, and tutorials to help you learn the ropes. Starting with pre-designed models (hello, Thingiverse!) can help you get the hang of printing before you dive into creating your own designs. And remember, practice makes perfect – or at least perfectly imperfect, which is half the fun!

Q5: For professionals, how does 3D printing integrate into traditional manufacturing processes?

A5: Great question! For professionals, 3D printing is like adding a Swiss Army knife to their toolbox. It excels in rapid prototyping, allowing for quick iterations and adjustments that significantly speed up the development process. It’s also becoming indispensable in custom manufacturing, where traditional methods fall short due to constraints in design flexibility or cost. Moreover, for short-run productions and creating complex geometries (think intricate medical implants or aerospace components), 3D printing shines where traditional methods might struggle. It’s all about complementing existing processes with a dose of innovation and efficiency.

Q6: Any future trends in 3D printing that both hobbyists and professionals should watch out for?

A6: The future looks bright and filled with layers upon layers of possibilities! For hobbyists, advancements in user-friendly software and multi-material printers promise to make 3D printing even more accessible and exciting. For professionals, keep an eye on the development of 4D printing – where structures are designed to change shape over time – and bioprinting, which could revolutionize fields like medicine and food production. Also, the continuous improvement in printer speeds and material science means that what’s cutting-edge today could be the new normal tomorrow. Buckle up – it’s going to be a thrilling ride!

Q7: Any parting advice for someone considering diving into 3D printing?

A7: Dive in headfirst, but be patient with yourself and your printer! Start with small, manageable projects and gradually challenge yourself with more complex designs. Join online forums and local makerspaces to exchange tips and troubleshoot issues – the 3D printing community is incredibly supportive and always buzzing with creativity. Most importantly, embrace the learning curve. Each print, successful or not, is a step forward in your 3D printing journey. Happy printing! 🚀

Wrapping Up

As you now sail away from the realm of 3D printing, you’re equipped with a map marked with the highs and lows that this groundbreaking technology brings to both hobbyists and professionals. Whether you’re imagining fantastical creations in your garage or engineering solutions in a high-tech lab, the possibilities that 3D printing offers are as limitless as your imagination.

Sure, navigating through its seas comes with storms—think of the investment in time, money, and occasionally, sanity, as your masterpiece prints into a tangled mess. But every innovation has its waves, and learning to surf them is part of the adventure. The joy when your printer hums to life and conjures your design into existence is nothing short of magical.

So, fellow creator, whether your path in the 3D printing world is paved with PLA or forged in metal, remember that every pro and con is a brushstroke in the grand portrait of modern innovation. Keep dreaming, keep tinkering, and most importantly, keep printing. Happy 3D adventures!