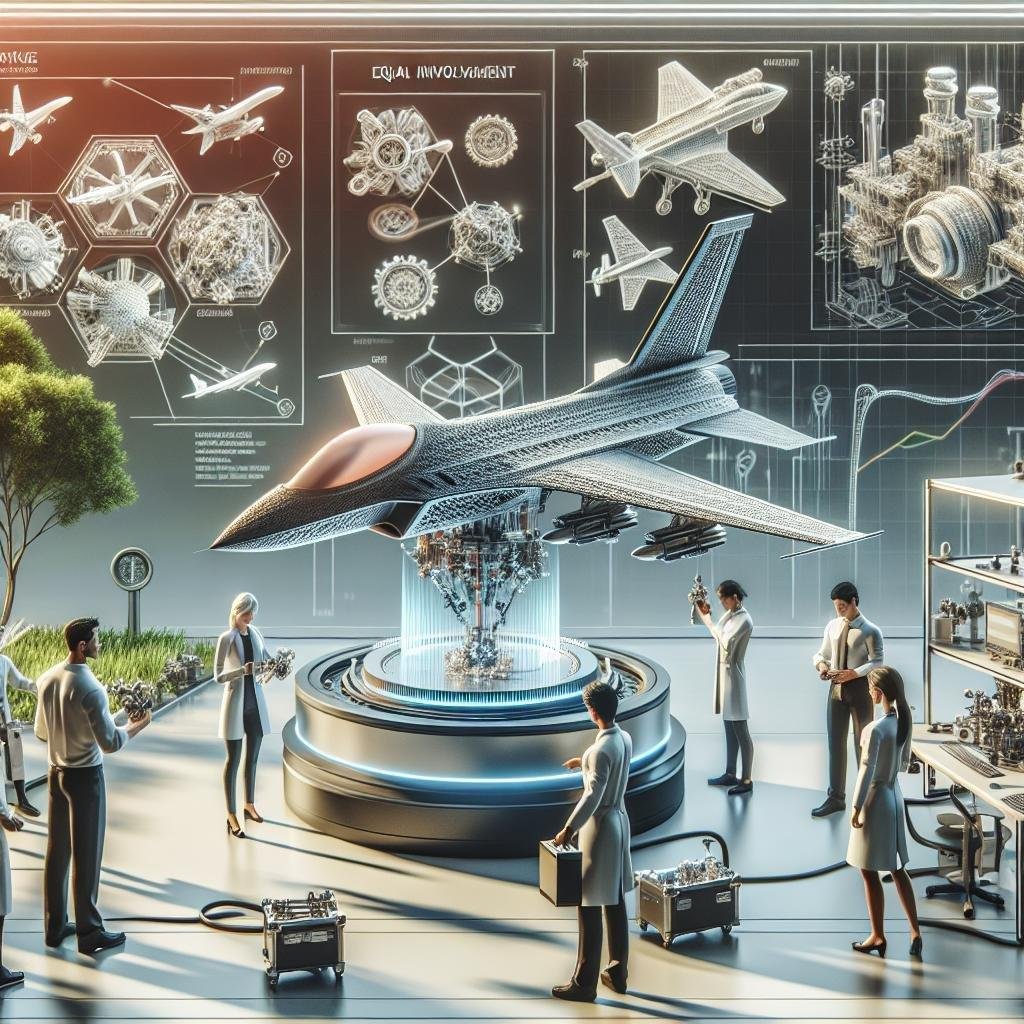

Imagine a world where entire aircraft are built layer by layer, each strand of metal or polymer perfectly tailored to form the sleek wings of a jet or the sturdy supports of a spacecraft. This isn’t the stuff of science fiction—this is the revolutionary reality of 3D printing in aerospace. As the hum of printers replaces the clang of machinery, innovation soars to new heights, offering exciting opportunities and provoking critical challenges. Welcome to the future of flight, where creativity knows no bounds, and the horizon expands with each new layer of material. Buckle up, dear reader, as we dive into the dazzling universe of 3D printing in aerospace, charting a course through its groundbreaking advancements and navigating the complex terrain of its hurdles. This is not just about building machines; it’s about crafting tomorrow’s sky-bound marvels one intricate detail at a time.

Exploring the Skies: Breakthroughs in Aerospace 3D Printing

The advent of 3D printing technology has revolutionized the aerospace industry, bringing about a wave of innovations that have significantly transformed how components are designed and manufactured. In the realm of aerospace, precision and reliability are paramount. 3D printing allows engineers to create intricate geometries and bespoke parts that were previously unimaginable with traditional manufacturing methods. This has paved the way for lighter, stronger, and more efficient components, optimizing fuel consumption and reducing emissions. Notable breakthroughs include:

- Custom Fuel Injectors: Enhancing engine performance and reducing fuel burn.

- Complex Engine Parts: Manufacturing parts with complex internal channels for better cooling and efficiency.

- Lightweight Structural Elements: Using advanced materials like titanium alloys and high-strength polymers.

Despite the impressive strides in aerospace 3D printing, the technology is not without its challenges. One of the primary hurdles is ensuring the consistency and quality of printed parts, which are critical for safety and performance in aerospace applications. The stringent industry standards require exhaustive testing and certification, adding time and cost to the development process. Additionally, the scalability of 3D printing for mass production remains a question, balancing cost-effectiveness with high-volume manufacturing demands. However, the potential benefits far outweigh the challenges, and continuous advancements in 3D printing technologies promise to surmount these obstacles.

Navigating the Hurdles: Addressing 3D Printing Challenges in Aviation

The aviation industry has increasingly turned to 3D printing for its ability to create complex, lightweight components. However, venturing into this realm with full-scale production comes with its unique set of challenges. Material certification remains a significant hurdle, as materials used for aviation parts must meet stringent safety and durability standards. Currently, metals such as titanium and aluminum are at the forefront, yet the certification process is labor-intensive and often slow-moving.

- Consistency and Quality Control: Ensuring each printed part meets the exact specifications and reliability is paramount.

- Cost and Scalability: Although 3D printing offers efficiency in prototyping, scaling production for high-volume parts demands substantial financial and logistical investment.

Another issue is software limitations. The design of aerospace components frequently involves complex geometries and stress analysis, requiring advanced software that’s still catching up to the rapid advancements in 3D printing technologies. Compatibility between different software platforms and printers can also lead to inefficiencies, contributing to longer production times and increased costs.

| Challenge | Impact | Solution |

|---|---|---|

| Material Certification | Delays in production | Streamlined approval processes |

| Consistency | Variable part quality | Rigorous quality control systems |

| Software Limitations | Increased costs and times | Integrated design and manufacturing software |

Elevating Efficiency: Practical Tips for Optimizing 3D Printing in Aerospace

In the vast frontier of aerospace, optimizing 3D printing processes can make the difference between soaring success and grounded ventures. Streamline material usage by selecting aerospace-grade materials such as lightweight titanium alloys or carbon fiber composites. These materials not only offer high strength-to-weight ratios but also enhance the performance and safety of the aerospace components. Utilize lattice structures which reduce weight without compromising on integrity, fostering more efficient fuel usage and payload capacities. Integrate in-process monitoring tools that detect anomalies during printing, ensuring parts are free from defects and meet stringent aerospace quality standards.

Another pivotal factor is the refinement of printer settings. Fine-tuning parameters like print speed, layer height, and infill density can drastically reduce print times and material waste. Post-processing enhancements such as thermal treatments or surface smoothing techniques can further polish the end product. Adopting these meticulous post-print strategies ensures the structural integrity and aesthetic appeal of the components. Regularly update and maintain printer firmware to incorporate the latest improvements and bug fixes.

| Parameter | Optimal Setting | Impact |

|---|---|---|

| Print Speed | 50 mm/s | Precision |

| Layer Height | 0.1 mm | Detail |

| Infill Density | 20% | Weight |

Consistency and attention to these details can significantly boost production efficiency and part reliability in the aerospace 3D printing landscape.

The Future of Flight: Predictions and Strategies for 3D Printing Advancements

3D printing is transforming the aerospace industry with its promise of customization, speed, and cost-effectiveness. The future of flight is being shaped by innovations that harness the power of additive manufacturing to produce complex geometries that traditional manufacturing methods can’t achieve. For instance, lightweight structures and fuel-efficient designs are becoming a reality, thanks to the ability to print parts with optimized internal configurations and aerodynamic qualities. The continuous evolution of materials used in 3D printing, notably high-performance polymers and metal alloys, is playing a crucial role, allowing for parts that withstand extreme conditions without compromising on strength or durability.

To stay ahead in this rapidly evolving landscape, aerospace companies need to adopt strategic approaches. Prioritizing research and development is vital to improve the quality and range of printable materials. Investing in collaborations with tech startups and academic institutions can bring fresh perspectives and breakthrough innovations. Equal attention should be given to aligning manufacturing processes with regulatory standards to ensure safety and reliability. Moreover, incorporating sustainability practices in production, such as using recycled materials and energy-efficient printers, can significantly reduce the environmental impact. Below is a table outlining some key strategies and their potential benefits:

| Strategy | Potential Benefit |

|---|---|

| Research & Development | Innovative materials and processes |

| Collaborations | Access to cutting-edge technologies |

| Regulatory Compliance | Enhanced safety and credibility |

| Sustainability | Reduced environmental footprint |

Q&A

Q&A: 3D Printing in Aerospace: Innovations and Challenges

Q1: What makes 3D printing a game-changer in the aerospace industry?

A1: Imagine constructing an airplane piece by piece, layer by layer, almost as easily as you would build with LEGO blocks! That’s essentially what 3D printing does for aerospace. It allows engineers to create complex, customized components with incredible precision and minimal waste. This revolutionary technology streamlines manufacturing processes, reduces lead times, and even trims down costs, all while enabling the creation of parts that were previously impossible to produce using traditional methods.

Q2: What kind of innovations are we talking about?

A2: Oh, the sky’s the limit! Literally. One of the coolest innovations is the printing of entire rocket engines. Companies like SpaceX and NASA are exploring 3D printed engines that can withstand the intense conditions of space travel. Besides that, lightweight parts for drones, satellites, and commercial airplanes are also being printed. These components can be designed to enhance strength while significantly reducing weight, which is a huge advantage in aerospace where every gram counts.

Q3: Are there any specific materials used in 3D printing for aerospace?

A3: Absolutely! It’s not your ordinary plastic stuff. Aerospace 3D printing predominantly uses advanced materials like titanium, high-strength aluminum alloys, and superalloys such as Inconel. These materials offer unparalleled strength-to-weight ratios and can endure extreme temperatures and pressures. Imagine printing with metals tougher than a marathon runner yet as light as a feather!

Q4: This sounds amazing, but are there any hurdles along the way?

A4: Indeed, not everything is smooth sailing—or smooth flying, in this case. One of the biggest challenges is ensuring the consistency and reliability of 3D printed parts. When you’re dealing with components destined for high-stakes environments like outer space or high-altitude flights, there’s zero room for error. Quality control and rigorous testing are critical, and establishing industry standards for these parts is still a work in progress.

Q5: How do engineers overcome these challenges?

A5: Think of engineers as modern-day alchemists. They’re employing advanced simulation software to predict how a part will behave before it’s even printed. After printing, parts undergo exhaustive testing including stress tests, heat tests, and even x-ray inspections to ensure there are no hidden flaws. Beyond that, continuous improvements in 3D printing technology, like enhanced precision and better material properties, are paving the way to overcome these obstacles.

Q6: How might this affect everyday people like you and me in the future?

A6: Fasten your seatbelts, because the future is coming in hot! The benefits of 3D printing in aerospace trickle down to consumers through cheaper flights, more efficient air travel, and safer journeys. Imagine boarding a flight and knowing that the aircraft is optimized for both performance and environmental impact, thanks to lightweight, durable 3D printed components. Plus, if space tourism takes off (no pun intended), these advancements will make space travel more accessible and affordable. One day, you might be saying, “I remember reading about 3D printing in aerospace, and now I’m taking a trip to the moon!”

Q7: Is there anything else exciting on the horizon for 3D printing in aerospace?

A7: You bet! The possibility of 3D printing on other planets is being actively researched. Imagine a future Mars colony printing its tools and structures using materials found on Mars! It may sound like sci-fi, but researchers are already developing 3D printers that could use local materials—like Martian regolith—to build habitats and equipment for astronauts. The potential for this technology to support interplanetary exploration is vast and incredibly thrilling.

Q8: How can someone get involved in this cutting-edge field?

A8: Great question! Getting started in this field usually means diving into engineering, material science, or computer-aided design (CAD). Many universities now offer specialized programs and courses focused on additive manufacturing and aerospace engineering. Internships and hands-on projects are invaluable too. Keep an eye on what companies in the aerospace sector are doing—internships, co-ops, and even entry-level positions can pave the way to a sky-high career.

Q9: Any final thoughts on 3D printing in aerospace?

A9: Just one: strap in, because this is just the beginning! As technology evolves, the fusion of 3D printing and aerospace promises to take humanity to new heights—both metaphorically and literally. So keep dreaming, keep innovating, and who knows? Maybe the next big leap in aerospace will come from your brilliant mind!

Feel as excited about the possibilities as we are? Stay tuned to our channel for more updates on the latest and greatest in 3D printing and aerospace innovation!

Future Outlook

As we close the chapter on our exploration of 3D printing in aerospace, it’s clear this revolutionary technology isn’t merely grounded in theory—it’s soaring among the stars. From cutting-edge innovations to the intricate challenges that lie ahead, 3D printing is reshaping the aviation landscape at breakneck speed.

Imagine a future where the limits of design are bound only by our creativity and where every component carrying us through the skies is a testament to human ingenuity. As the horizons expand, so does our potential to redefine what’s possible. Whether you’re an industry professional, a tech enthusiast, or a passionate observer, 3D printing beckons with the promise of a new era.

So, let’s buckle up, keep our eyes on the stars, and embrace the journey. The sky’s not just the limit—it’s the launching pad.

Until next time, may your flights be smooth and your innovations boundless! 🚀 ✈️