In a world that teeters on teh brink of resource depletion, where the intricate dance between consumption and conservation wields far-reaching consequences, a new maestro steps onto the stage: 3D printing. This avant-garde technology, once the stuff of science fiction, is now not only shaping objects but also shaping futures, offering tantalizing possibilities for lasting and circular economies. Imagine a world where the mantra “reduce, reuse, recycle” evolves from a noble aspiration to a dynamic reality, powered by printers that spin dreams into tangible, eco-kind products. Welcome to the dawn of a manufacturing revolution-where creativity meets conservation, and where every print is a step towards a more sustainable future.

Reimagining Resources the 3D Printing Revolution

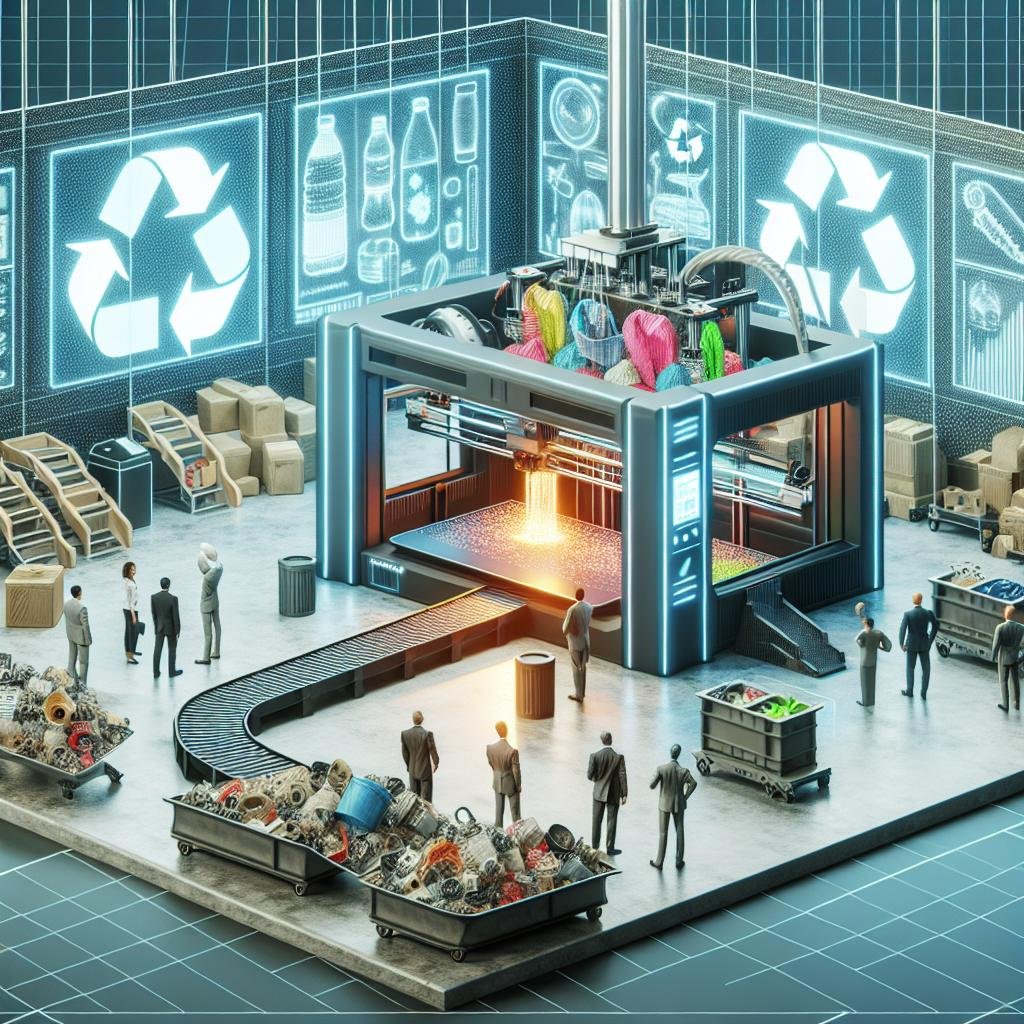

The advent of 3D printing technology has marked the beginning of a transformative era in how we view and utilize resources. This innovation is empowering businesses and individuals alike to cultivate sustainable practices by minimizing waste and maximizing efficiency. Additive manufacturing, as it’s also known, transforms the customary path of manufacturing by building objects layer by layer, only using the material necessary for the final product. This method significantly reduces excess and helps in achieving a circular economy by recycling waste materials back into the production cycle. Individuals and companies are seizing this chance to be more resource-efficient by experimenting with bio-plastics, recycled metals, and even concrete alternatives to ensure that materials travel a never-ending loop instead of ending up in landfills.

- Resource Efficiency

- Reduced Waste

- Creative material Use

Moreover, 3D printing accentuates the transition from a linear to a circular economic model by facilitating innovations that focus on product longevity and secondary use. Imagine furniture designed to be easily dismantled and reassembled into new pieces, or spare parts printed on-demand to extend the life of electronic devices. The accessibility of 3D printers also fosters community-level sustainability practices. Local makers can craft custom solutions specific to community needs, like fabricating low-cost prosthetics or creating parts for agricultural equipment, aligning with their unique environmental and economic circumstances. The implications for renewability and customization are plentiful, driving societies towards a more responsible and connected future.

| Aspect | Impact |

|---|---|

| Material Usage | Reduced |

| Community Involvement | Increased |

| Innovation in Sustainability | Enhanced |

Crafting a Greener Tomorrow with Additive Manufacturing

With the relentless push towards more sustainable practices, 3D printing technologies are spearheading a transformative approach that not only reduces waste but also enhances resource efficiency. By enabling localized production and customization, this innovation encourages eco-friendly manufacturing processes tailored to specific needs. Imagine a world where excess material can be minimized, raw materials sourced locally, and goods designed for durability and adaptability. This is the promise of additive manufacturing.

One of the exciting aspects of this revolution is its potential contribution to a circular economy. rather of a linear take-make-dispose model, 3D printing paves the way for the creation of sustainable products designed with their end-of-life in mind.Consider how products can be designed for disassembly and recycling,reducing not only material waste but also energy consumption during production. The potential is limitless with ideas such as:

- Material efficiency: Using only what is necessary without excess.

- decentralized production: Reducing transportation emissions and costs.

- Recycling and reusing: Incorporating recycled materials into new creations.

| aspect | Potential Impact |

|---|---|

| Waste Reduction | Up to 90% less material waste |

| Energy Efficiency | Lower energy usage by 50% |

| customization | Improved product lifespan by 30% |

from Waste to Wonder Exploring Circular Practices in 3D Printing

In the ever-evolving landscape of manufacturing, 3D printing is pioneering a shift towards a more sustainable and circular approach. By transforming waste into resources, this revolutionary technology supports an innovative cycle of use, reuse, and recycling. Gone are the days when printing materials were fresh out of the factory; today, we see an increasing trend of utilizing discarded plastics and metals as feedstock. This reduction in reliance on virgin materials not only cuts costs but also minimizes carbon footprints. Through ingenious practices like plastic filament recycling and metal powder reusability, 3D printing is becoming increasingly sustainable and environmentally responsible.

Furthermore, the possibilities of combining artistry with sustainable living are opening new avenues for creativity. Artists and designers are leveraging circular practices to create unique, eco-friendly pieces. These innovations are powered by technologies that support the creative use of reclaimed materials, bringing new life to what was once considered waste. Consider the following strategies in circular 3D printing:

- Utilizing biodegradable materials such as PLA.

- Employing reclaimed plastics and metals like PETG and recycling-based powders.

- Incorporating automated systems for meticulous material sorting and processing.

| Practice | Benefits |

|---|---|

| Recycled Filaments | Reduces plastic waste; cost-effective |

| Biodegradable Materials | Eco-friendly; reduces landfill impact |

| Closed-loop systems | Improves resource efficiency; reduces resource depletion |

Blueprints for a Sustainable Future Recommendations for Eco-Friendly Innovations

The realm of 3D printing is evolving rapidly, and its potential to foster a sustainable and circular economy is both innovative and promising. This technology allows for on-demand production, which significantly reduces waste by eliminating excess inventory. By using biodegradable or recycled materials as filament, companies can lower their ecological footprint, aligning manufacturing processes with eco-friendly principles. Among industries, it has already started to revolutionize areas like fashion, architecture, and automotive, by using less material and energy. In this transformative journey, fostering local production hubs means reducing the need for shipping and transportation, thereby cutting down on fossil fuel dependency. These production hubs act like community makerspaces, allowing individuals to create and innovate locally, fueling both community spirit and environmental stewardship.

Moreover, 3D printing encourages a mindset of sustainability thanks to its ability to repair, repurpose, and recycle. Rather than discarding broken items, they can be easily repaired with printed spare parts. Additionally, the ability to recycle 3D printed products into new filament offers a closed-loop system. Some companies are already embracing this idea, creating printed products designed to be recycled back into the production cycle. These innovations open up pathways for increased resilience and responsiveness to environmental challenges. Consider the following benefits of 3D printing for sustainability:

- Material Efficiency: Uses exact amounts necessary, reducing waste.

- Customization: Personalization reduces mass production and excess stock.

- Decentralization: Local production lowers carbon emissions and supports local economies.

| Key benefit | Impact |

|---|---|

| Renewable Filament | Reduces dependence on non-sustainable materials. |

| On-Demand Manufacturing | Decreases overproduction and inventory waste. |

| Closed-loop Cycle | Enhances material reutilization. |

Q&A

Q&A: 3D Printing for sustainable and Circular Economies

Q1: what exactly is 3D printing, and why is it considered a game-changer for sustainable and circular economies?

A1: Great question! 3D printing, also known as additive manufacturing, involves creating three-dimensional objects from a digital file by adding material layer by layer. It’s like magic in slow motion! For sustainable and circular economies, 3D printing is revolutionary because it allows for efficient use of resources, minimizes waste, and can even use recycled materials to produce new products. Imagine creating items only when needed and precisely where needed. That’s a win-win for the planet and production efficiency!

Q2: How does 3D printing help reduce waste?

A2: Ah, the beauty of layer-by-layer! Traditional manufacturing often involves cutting away excess material, which can be wasteful. In contrast, 3D printing only uses the material necessary for the object being made, significantly cutting down on waste. Plus, many 3D printers can use recycled materials, turning yesterday’s waste into tomorrow’s innovations. It’s like the ultimate eco-friendly craft project!

Q3: Are there any real-world examples of 3D printing being used in circular economies?

A3: Absolutely! Take, for instance, the fashion industry, where 3D printing is used to create stunning pieces using recycled plastics. Or consider construction, where companies are 3D printing entire houses with sustainable materials. There are even projects where broken parts are scanned, repaired, and re-used instead of tossed. These initiatives are just the beginning, showing how industries can transform waste and rethink production for a more sustainable future.

Q4: What challenges does 3D printing face in becoming a cornerstone of circular economies?

A4: Every innovation has its hurdles, right? For 3D printing, some challenges include the need for further development in recyclable printing materials, energy consumption during the printing process, and the scalability for mass production.Additionally,there are regulatory and standardization issues that need ironing out to ensure safety and quality. But as they say, every problem is an opportunity in disguise!

Q5: What can I do to support 3D printing in sustainable practices?

A5: You’re in luck – there’s plenty you can do! Start by supporting businesses and products that embrace 3D printing for sustainability. Vote with yoru wallet! You can also advocate for policies that encourage innovation in sustainable technologies. If you’re feeling adventurous,explore personal 3D printing projects at home using biodegradable or recycled filaments. Be a part of the shift – every action counts!

Q6: So, what’s the future looking like with 3D printing leading the charge in circular economies?

A6: The future is radiant and creatively responsible! With continued advancements, 3D printing holds the promise of more localized production, reduced carbon footprints, and innovation-driven economies that prioritize regeneration over waste. It’s like having a toolset for building a better tomorrow, where products are made with intention and cycles replace linear consumption.Buckle up, because the 3D printing revolution is just getting started, and it’s bring-your-own-imagination!

Conclusion: Embracing 3D printing could very well be a pivotal step toward achieving sustainable and circular economies. The technology brings hope and creativity into harmony,promising a future where Earth’s resources are cherished and efficiently used.Let’s 3D-print that future together!

The Conclusion

As we stand at the crossroads of innovation and responsibility, 3D printing emerges not just as a beacon of technological advancement, but as a powerful tool in our quest for a more sustainable world. By weaving the threads of creativity, efficiency, and resilience, it holds the promise of unraveling the complexities of a circular economy. From repurposing materials to fostering localized production,3D printing offers a path towards a future where waste is a relic of the past and resources are cherished treasures. As you explore the potential of this revolutionary technology,imagine the world we can build-layer by layer,innovation by innovation-a world where sustainability and progress are not just intertwined,but in harmony. Let us print the blueprint for a better tomorrow.